When the dry ball mill is running, the material enters the first bin of the mill by the feeding device. The bin is equipped with stepped liner or corrugated liner and steel balls of

获取价格

MINING. Ball Mill Liners for Mineral Beneficiation. Polycorp has a long, successful heritage in the mining industry, and is recognized as an international supplier of premium Mill

获取价格

Ball mill Most ball mills, even in primary applications, have a finer ore feed size; this requires some impact but not enough to increase the media consumption or even break

获取价格

2019/8/14 5. The size of the ball mill is large, and it is necessary to carry out lifting work during the process of replacing the ball mill liner. The hoisting ball mill liner is the

获取价格

Download Alloy Specifications for FC ProLiner™. FC ProLiner™ liners are produced to ASTM international specifications and offer good corrosion resistance and excellent abrasion resistance while offering medium

获取价格

When the ball mill installs the liner, a layer of 1:2 cement mortar should be applied between the inner wall of the cylinder and the liner, and the liner bolts should be tightened while

获取价格

key factors affecting mill throughput and grinding efficiency: mill speed, ball loading, and liner lifter face angle (angle between the lifter face in contact with a grinding ball and the

获取价格

2017/10/25 The critical speed, Nc, in revolutions per minute, is a function of the mill diameter, D, expressed as: Nc = 42.3/√D (meters) or Nc = 76.63/√D (feet) In practical terms, one must assume some mill

获取价格

2020/5/19 The ball mill liners are located on the inner surface of the ball mill barrel, which protects the barrel from the direct impact and friction of the grinding media and the material. The ball mill liners’ material and

获取价格

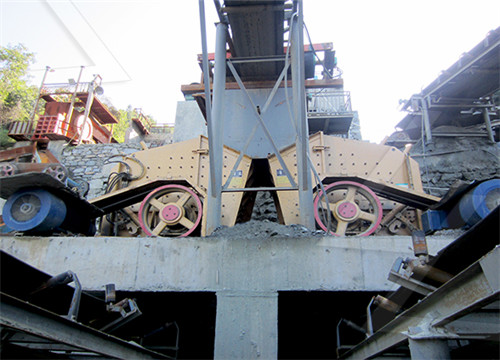

Ball Mill is a mineral processing machine for milling the materials into powders after they are crushed. +8613917147829 ... There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the ...

获取价格

The ball mill cylinder is a hollow barrel, which is rolled and welded by several steel plates. The two ends of the cylinder are connected to the ball mill trunnion with end covers. As the main part of the ball mill, it has to

获取价格

The workshop needs to have good ventilation conditions and suitable temperature. Then the installer can enter the ball mill barrel to start the operation. When removing the old ball mill liner, first remove the used lining screws, then remove the old ball mill liner one line after one line, and then lift the used ball mill liner.

获取价格

2021/1/1 Ball mill is a kind of raw material processing machinery which plays the role of grinding. Its working principle is that the movement and force are transmitted to the barrel of ball mill through ...

获取价格

STEEL MILLING BALLS FOR BALL MILLS Specifications _____ Date of validity:1998.01.01 1. FIELD OF APPLICATION ... cement and other materials in ball mills. 2. NORMATIVE REFERENCES This standard hasthe references on the following documents: GOST 12.2.003-91 Occupational safety standard system.Industrial

获取价格

Liner of ball mill is made of high-quality wear resistant material with high strength, wear resistance and long working life. The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard.

获取价格

The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials. Vertical ball mill can be widely used for dispersion and grinding of solid or powder materials in paint, medicine, building materials, chemical industry and other industries.

获取价格

Afquip Africa offer Mill Liners for SAG, AG, Rod and Ball Mills in a range of material specifications according to client requests, Mill type and Liner Profiles which include Manganese, Manganese Chrome, High Chrome, Ni-Hard 4 and or other specific requirements. ... Afquip Africa is capable of offering Mill Liner designs services which

获取价格

2015/8/6 Ball Mill The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material ...

获取价格

Dry ball mill: the material is brought out by the air flow drawn out of the barrel; Wet ball mill: the material is discharged out of the cylinder through the discharge part with the ... is equipped with stepped liner or corrugated liner and steel balls of

获取价格

High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation. A list of the primary material of construction ...

获取价格

2021/1/1 Ball mill is a kind of raw material processing machinery which plays the role of grinding. Its working principle is that the movement and force are transmitted to the barrel of ball mill through reducer, transmission shaft and hollow shaft by motor. ... Yao Y M. 2010 Kinematic analysis of ball mill ball and its influence on liner plate [D ...

获取价格

Compared with the metal lining of the mill, the harder the ore is, the more wear-resistant the rubber lining of the mill is than the metal lining, so the rubber lining is more suitable for the environment where the ore hardness is higher in the mill. Steel ball diameter: The steel ball used for rubber-lined mills should generally be around ...

获取价格

Dry ball mill: the material is brought out by the air flow drawn out of the barrel; Wet ball mill: the material is discharged out of the cylinder through the discharge part with the ... is equipped with stepped liner or corrugated liner and steel balls of

获取价格

High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation. A list of the primary material of construction ...

获取价格

2021/1/1 Ball mill is a kind of raw material processing machinery which plays the role of grinding. Its working principle is that the movement and force are transmitted to the barrel of ball mill through reducer, transmission shaft and hollow shaft by motor. ... Yao Y M. 2010 Kinematic analysis of ball mill ball and its influence on liner plate [D ...

获取价格

Compared with the metal lining of the mill, the harder the ore is, the more wear-resistant the rubber lining of the mill is than the metal lining, so the rubber lining is more suitable for the environment where the ore hardness is higher in the mill. Steel ball diameter: The steel ball used for rubber-lined mills should generally be around ...

获取价格

overflow ball mills and grinding ball mills. By using special alloy steel segments moulded into rubber, composite plates greatly reduce the liner breakage risk, present in the grinding process where balls of over 100mm are used. In addition, composite linings are up to 35-50% lighter than their metal equivalents. This translates into an

获取价格

The mill liner is installed inside the ball mill barrel to protect the inner wall of the barrel from the impact of materials and grinding media (steel balls, steel sylpebs, steel rods, etc.) to avoid premature damage to the barrel.As an important part of the ball mill, the mill lining needs to be designed according to the materials to be processed and different grinding

获取价格

Ball mill liner or ball mill linning is lined with ball mill barrel, to protect the wall of ball mill barrel from being damaged by the impact of material and steel balls. At the same time, the movement state of the grinding medium in the barrel can be adjusted through different liner shapes, which can help the grinding medium to better grind the materials, and enhance

获取价格

The design of ball mill linings plays a crucial role in optimizing the efficiency and performance of the milling process. The ball mill, a key equipment for grinding materials, operates by rotating a cylinder filled with steel grinding balls. Understanding why ball mill lining design matter is essential for improving overall productivity and minimizing wear []

获取价格

A section cut-through of ball mills. A ball mill is a type of grinder filled with grinding balls, used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

获取价格

The material is crushed by the balls which are embedded in a container or a compartment. This type of grinder is also used for mixing and blending materials for paints, ceramics and pyrotechnics etc. ... This is because a ball mill liner protects the barrel of a ball mill by reducing the friction of abrasive materials and body on it ...

获取价格

When the ball mill installs the liner, a layer of 1:2 cement mortar should be applied between the inner wall of the cylinder and the liner, and the liner bolts should be tightened while wet. The gaps between the liners are also smoothed with sand and grout. 2. Before installing the liner of the ball mill, the liner should be inspected and trimmed.

获取价格

Unique designs various ball mill drive options, including standard shaft mount, gearwheel, pinion direct drive ball mills and more. ... Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with ...

获取价格

2022/5/18 Cone ball mill is the horizontal barrel rotating device. The material is evenly entered into the first chamber by the feeding device through the incoming hollow shaft spiral, which has a step ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين