2023/9/30 The global decrease in ore mineral grades and increase in ore mineralogical complexity has triggered the modern mining industry and research

获取价格

2024/8/1 1. Introduction. Sulfides are ubiquitous in various metal deposits and are usually important carriers of useful metal elements (Jean and Michael, 1985, Hyland and

获取价格

2024/3/10 The gold ore CIP processing method, that is, the carbon slurry method for extracting gold, is an important type of modern gold extraction technology. Its core is to use activated carbon’s strong ...

获取价格

2022/3/1 In the context of its processing, gold deposits are typically classified, for the purposes of simplification, as: 1) free milling, and 2) refractory ores (including

获取价格

Bornite (Cu5FeS4), covellite (CuS) and chalcocite (Cu2S) are important sources in the world, and many ore bodies also contain some malachite (CuCO3.Cu(OH)2), azurite

获取价格

2022/10/15 The gold leaching percentage and thiosulfate consumption of cobalt-glycine system are 94.85 % and 17.38 kg/t-ore, it has higher gold leaching percentage

获取价格

Using life cycle assessment to evaluate some. 2 e/t Au, 260,000 t water/t Au and 1,270,000 t waste solids/t Au for non-refractory ore. The embodied energy and greenhouse gas

获取价格

2013/2/20 Developments of Processing Technologies for Refractory Gold Ores. ... School of Metallurgical Science and Engineering, Central South University, Changsha

获取价格

2015/9/15 Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized

获取价格

Shaxi Copper Mine in Anhui, was the largest gold-producing mine in China, producing approximately 946.4 thousand ounces of gold and an estimated 4.3 million metric tons

获取价格

Precious metals mineral processing plant refers to gold, silver, and platinum group metals, especially the gold mining and peocessing plant solutions, including flotation and gravity separation, CIL, CIP process,

获取价格

Pursuing precious metals has long been rooted in human history, with gold processing standing as a testament to our evolving mastery over the natural world. The transformation of gold from raw ore to a refined state

获取价格

2024/8/1 1. Introduction. Sulfides are ubiquitous in various metal deposits and are usually important carriers of useful metal elements (Jean and Michael, 1985, Hyland and Bancroft, 1989, Maddox et al., 1998, Abraitis et al., 2004, Deditius et al., 2008, Prol-Ledesma et al., 2010).Pyrite, the primary sulfide mineral in gold deposits, also serves as

获取价格

2024/3/20 Master the gold processing steps with our comprehensive guide. Explore the essential steps for gold processing in our latest blog post. ... The World Gold Chamber says that in 2020, the nations that delivered the foremost gold were China, Russia, Australia, the United States, and Canada. ... The gold ore straight from the mine gets

获取价格

China. Jiangxi 1000t/d fluorite ores processing project; Shandong 2000t/d gold project; Hebei 3600t/d Lithium ores processing project; Gansu 1000t/d copper project; Europe. ... Flotation is a method that is widely used in gold ore processing plant to process the rock gold , commonly used in dealing with highly floatable sulfide minerals ...

获取价格

Heap leaching of gold ore is to crush low-grade gold ore to a certain size (or granulate) and pile it on a leak-proof bottom mat paved with materials such as asphalt, concrete or plastic cloth, and use low-concentration cyanide, alkaline solution, Solutions such as non-toxic solvents or dilute sulfuric acid are sprayed on the mine pile to dissolve the gold, and the

获取价格

Lipu Heavy Industry Co.,Ltd - Mining Machines Ball Mill ... اقرأ أكثر

获取价格

2019/6/15 1. Introduction. The use of dilute sodium cyanide or potassium cyanide solutions for the leaching of gold and silver from their ores was known as early as 1888 (Marsden and House, 2006).Cyanidation process has been the most successfully practiced method for gold extracting from ores over the past 100 years.

获取价格

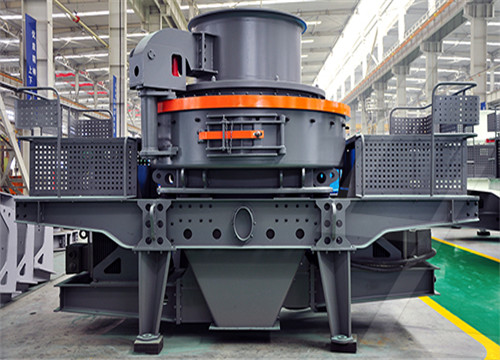

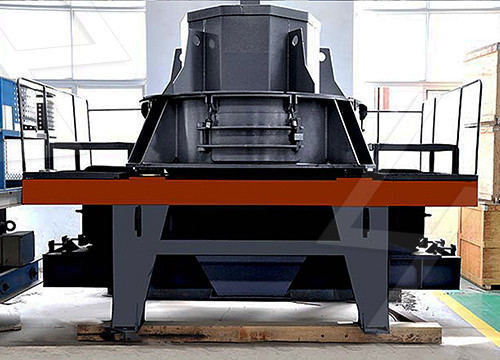

It is a professional China manufacturer of crushers and beneficiation equipment. ... Gold Ore Processing. Carbon-in-pulp ... and solutions. China Mining Equipment Manufacturer. Contact Tel: +86-13879771862 E-Mail: [email protected] Main Equipment. Crushing Screening; Grinding Classifying;

获取价格

2021/4/1 Typically, gold is encapsulated or finely disseminated in refractory gold ores and the direct cyanidation is not effective for gold extraction from these ores, even after the ore is ground to exceeding small particles (Nazari, 2017, Corrans and Angove, 1991).Especially for sulfide refractory gold ores, in order to recover gold, many

获取价格

chalcopyrite. These ores are often refractory, as the gold is encapsulated within the sulfide matrix. In order to recover the gold, the host matrix must be destroyed. Over the past 100 years, roasting or smelting has been the dominant method for oxidising sulfide bearing gold ores and concentrates. However, with the cost associated with treating SO

获取价格

Here is the brief introduction of this very popular gold ore processing technology in the world. We do beleive that your gold ore processing business will be more sucessful by choosing Zenith. 1. The CIL process technology. The ore is ground and concentrates are produced by means of conventional flotation and gravity circuits.

获取价格

2016/2/29 Process Development Considering the different gold minerals present alone or combined with the host rock, it will be necessary to discharge the unwanted material in order to increase the concentration of gold in an economically manner. This part treats the strategy of beneficiation as a combination of several processes. Joining

获取价格

1 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the over-crushing of ore, and at the same time it can increase the output per unit volume. 1. Large row of ore mouth design, stronger processing capacity for lithium ore, up to 160t/h; 2. Equipped with an automatic control system PLC, reducing labor costs, real

获取价格

chalcopyrite. These ores are often refractory, as the gold is encapsulated within the sulfide matrix. In order to recover the gold, the host matrix must be destroyed. Over the past 100 years, roasting or smelting has been the dominant method for oxidising sulfide bearing gold ores and concentrates. However, with the cost associated with treating SO

获取价格

Here is the brief introduction of this very popular gold ore processing technology in the world. We do beleive that your gold ore processing business will be more sucessful by choosing Zenith. 1. The CIL process technology. The ore is ground and concentrates are produced by means of conventional flotation and gravity circuits.

获取价格

2016/2/29 Process Development Considering the different gold minerals present alone or combined with the host rock, it will be necessary to discharge the unwanted material in order to increase the concentration

获取价格

1 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the over-crushing of ore, and at the same time it can increase the output per unit volume. 1. Large row of ore mouth design, stronger processing capacity for lithium ore, up to 160t/h; 2. Equipped with an automatic control system PLC, reducing labor costs, real

获取价格

2023/12/6 A 10TPD Mobile Gold CIL Plant is a compact and portable gold processing plant that can be used to extract gold from ore samples or tailings. It is designed to be easy to transport and set up, making it ideal for small-scale gold mining operations or use in remote locations. Processing Capacity The plant has []

获取价格

The principal technology is the cyanide process, in which gold is leached from the ore by treatment with a solution of cyanide. The first step is comminution (grinding) to increase surface area and expose the gold to the extracting solution. The extraction is conducted by dump leaching or heap leaching processes. Sodium cyanide is produced on a billion

获取价格

2023/6/12 10TPH Oxidation Gold Ore Processing Plant in Tanzania. 4. Gold sulfide ore ... because it dissolves very slowly in cyanide solutions. Therefore, it is usually roasted to decompose gold telluride compounds. ... No.168, Wutong Street, High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China. Phone No./WhatsApp:

获取价格

Where high grade feeds or solutions are treated the number of adsorption stages is consequentially higher. If the feed grade is 18 Au g/tonne the following would be expected. (assuming 50% stage efficiency). ... When dealing with processing a copper gold ore there are a number of processes that can be considered. In order to eliminate unlikely ...

获取价格

2015/9/15 Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page

获取价格

2022/3/1 The aim of this paper is to present a systematic review of the mineral processing of gold ores, with special focus on alternative leaching reagents to cyanide that can facilitate more sustainable extraction. ... This process is non-toxic and is faster than typical cyanide-based solutions when used on several ores, concentrates and tailings. A ...

获取价格

refractory gold minerals; locking of submicroscopic gold in sulfide and sulfarsenide mineral structures. Gold process mineralogy address all issues related to gold ore processing by the detailed study of an ore or a mill product. The methodology is widely used as a predictive tool in feasibility studies and during the process

获取价格

2016/1/1 Early work examined acidic thiocyanate solutions to recover gold and uranium simultaneously from South African gold ores (Fleming, 1986). Several studies on leaching rates, mechanisms, and thermodynamics of the thiocyanate system have been published by Monhemius and coworkers ( Barbosa-Filho and Monhemius, 1994a ,

获取价格

2023/6/28 Establishing a GOLD CIP PLANT with a production capacity of 100 tons per day requires careful planning and execution. This article aims to highlight potential challenges associated with investment, site selection, infrastructure, equipment requirements, operation, and support services. Moreover, it emphasizes the significance

获取价格

Gold carbon-in-pulp(CIP) is a typical gold beneficiation process for the effective recovery of gold-bearing minerals with a high oxidation degree and low grade of raw ore. Gold CIP has become a widely used gold extraction method worldwide because of its advantages of high adsorption rate, high recovery rate, and low investment cost.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين