Introducing the Cone Crusher. Cone crushers take care of secondary and tertiary crushing applications. Fine and medium-sized aggregates (used in asphalt and concrete, for

获取价格

2024/3/20 Jaw crushers and cone crushers are exceedingly effective and flexible. They can handle a wide run of mineral metals, and this makes them fundamental within the mining industry. Their capabilities

获取价格

2023/10/20 However, cone crushers also have the following disadvantages: 1. The rotating body is higher, generally 2-3 times higher than the jaw crusher, so the

获取价格

Also is the most mainstream crusher type. Jaw crusher is usually used as a primary crusher and second-class crusher. Cone crusher is usually used as secondary crusher or three-stage crusher machine. Jaw crusher

获取价格

Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary

获取价格

Applications Suitable for Jaw Crushers. Jaw crushers are typically used in a scenario that requires a reduction ratio of 10:1. A jaw crusher 30” opening has a 3-inch minimum closed side setting. Jaw crushers have diverse

获取价格

2021/5/20 In general, fine jaw crusher and cone crusher have the following characteristics: The feeding granulation range of fine jaw crusher is relatively large,

获取价格

2016/1/17 The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether

获取价格

2019/5/30 The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers. Cone crushers have traditionally been used as secondary and ...

获取价格

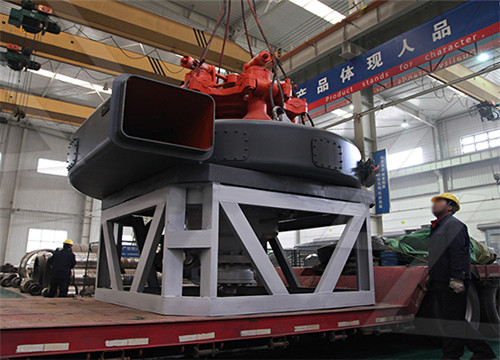

Introducing the Cone Crusher. Cone crushers take care of secondary and tertiary crushing applications. Fine and medium-sized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall. The Blackhawk 100 Cone Crusher is an example of a ...

获取价格

2022/3/22 In the mining industry, the most common crusher types are jaw crusher and cone crusher. Jaw crusher is usually used for primary crushing, and cone crusher is used for secondary crushing. ... There is an oil pressure difference between the oil pipes of the filter. Reason: The filter is blocked. Solution: if the difference is more than 0.04 MPa, ...

获取价格

Welcome to our blog post on the difference between smooth roll crushers and jaw crushers! If you’re in the mining or construction industry, chances are you’ve encountered these two types of crushing machines before. While both serve the same purpose of reducing large rocks into smaller stones or gravel, they have distinct characteristics ...

获取价格

TOP quality parts for cone crusher and jaw crusher. Symons cone crusher 2, 3, 4, 4 1/4, 5, 7. Sandvik CH420, CH430, CH440, CH660, CH880, CS420, CS430, CS440, CS660.

获取价格

2023/10/20 Which type of crusher is right for you? The best type of crusher for you will depend on your specific needs. When selecting coarse crushing equipment in the design, the nature of the ore, the particle size requirements of the product, the scale of the dressing plant and the configuration conditions of the equipment should also be

获取价格

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a

获取价格

CONE CRUSHER QM SERIES . Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw. The higher cavity density improves the

获取价格

2020/6/3 Cone Crusher vs. Jaw Crusher: Key Differences. While companies use both machines for crushing raw materials, several vital differences may make one type of crusher better than the other for your application. How They Work. The primary difference between the two is how they crush material.

获取价格

2023/2/3 The primary difference between an impact, cone, and jaw crusher is the type of crushing force they use. An impact crusher uses dynamic force to break down materials, whereas a cone crusher uses a ...

获取价格

2024/2/5 Cone Crusher, Impact Crusher: Usually between 125 mm and 150 mm: Further reduced to 20 mm to 40 mm. The material from the primary crusher is fed into secondary crushers for a more uniform and finer size. Tertiary Crushing: To obtain even finer material suitable for specific requirements. Fine Jaw Crushers, Cone Crushers

获取价格

What is the difference between a jaw crusher and a cone crusher? Primary vs. Secondary Crushing: Jaw crushers are primarily utilized for initial material reduction crushing tasks, while cone crushers are used in secondary crushing, refining materials that have already undergone primary crushing stages.

获取价格

A cone crusher, on the other hand, doesn't have a movable jaw. Instead, it has two plates that rotate around an axis. This allows the crusher to reduce the size of materials by breaking them into smaller pieces. Jaw crusher vs cone crusher. The main difference between jaw crusher and cone crusher is the shape of their crushers.

获取价格

2023/2/3 The primary difference between an impact, cone, and jaw crusher is the type of crushing force they use. An impact crusher uses dynamic force to break down materials, whereas a cone crusher uses a ...

获取价格

2024/2/5 Cone Crusher, Impact Crusher: Usually between 125 mm and 150 mm: Further reduced to 20 mm to 40 mm. The material from the primary crusher is fed into secondary crushers for a more uniform and

获取价格

What is the difference between a jaw crusher and a cone crusher? Primary vs. Secondary Crushing: Jaw crushers are primarily utilized for initial material reduction crushing tasks, while cone crushers are used in secondary crushing, refining materials that have already undergone primary crushing stages.

获取价格

A cone crusher, on the other hand, doesn't have a movable jaw. Instead, it has two plates that rotate around an axis. This allows the crusher to reduce the size of materials by breaking them into smaller pieces. Jaw crusher vs cone crusher. The main difference between jaw crusher and cone crusher is the shape of their crushers.

获取价格

2023/2/24 Unlike the Blake Jaw Crusher, the Dodge Jaw Crusher has a movable jaw that moves back and forth like a pendulum, while the fixed jaw remains in a stationary position. As the material is fed into the crushing chamber, it is crushed by the movement of the movable jaw against the fixed jaw.

获取价格

2024/2/18 Next Impact Crusher vs Jaw Crusher: What’s the Difference? Next. mmldigi February 18, 2024 10:46 am A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. Comprising type of jaw crusher—the robust Single-toggle and the efficient

获取价格

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be

获取价格

Jaw crusher is suitable for crushing various soft and hard materials with compressive strength between 300-350Mpa. The models and specifications of ZENITH jaw crushers are all complete. There are coarse jaw crusher and fine jaw crusher for customers to choose, mainly used for the primary crushing operation of materials.

获取价格

2020/2/28 It mainly crushes the small material discharge from the jaw crusher. In general, the jaw crushers are placed before the impact crusher. 2. Capacity. 1. Jaw crusher can crush various materials with compressive strength below 320MPa, particle size between 125mm – 750mm. capacity up to 500 TPH. Most jaw crusher manufacturers

获取价格

The jaw crusher handles the initial crushing, reducing the material to a size suitable for the cone crusher. The cone crusher then refines the material further, producing a more consistent and finer output. Conclusion. The size distribution produced by jaw and cone crushers differs significantly, with each crusher type offering unique benefits.

获取价格

Cone crushers. Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

获取价格

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of

获取价格

2021/11/1 Fig. 3 illustrates the operating principle and the main components of a cone crusher. A cone crusher basically comprises two bell-shaped manganese crushing liners placed inside each other. The concave is attached to the crusher frame and the mantle to the eccentric main shaft which is swaying around the geometric center point at

获取价格

2023/2/15 Mobile cone crushers are typically used in secondary and tertiary crushing stages in mining, quarrying, and recycling applications. The mobile cone crusher is designed to be easily transported between sites and is usually mounted on tracks, which provides flexibility in terms of the types of terrain that it can operate on.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين