1997/1/1 Abstract. A series of processes has been developed to recover the gold from electronic scrap containing about 200~600 ppm Au. First, mechanical beneficiation

获取价格

e cient manner. The use of an acidic ferric chloride solution, ffi. along with simultaneous electrowinning, results in a higher weight percentage of gold in the remaining solid

获取价格

2024/3/22 Stir daily for a week. For gold flakes recovery, use a solution of hydrogen peroxideand muratic acidto dissolve the adhesive on computer parts, then process with sodium bisulfatefor gold precipitation.

获取价格

Download Free PDF. Download Free PDF. ... Table 4 Summary of selected US patents related to gold extraction/recovery US Patent No. Title 4,578,163 Gold recovery

获取价格

2022/8/1 develop a gold recovery process compa rable to the cyanidation carbon in the pulp process. Ion Ion exchange may be an efficient proce ss to recover gold from the halide lixivium.

获取价格

2016/2/29 If the solution is rich enough can be treated by zinc powder and the precipitated obtained (cement) obtained will be sent to retorting and smelting. For gold extraction the strength of cyanide solution ranges

获取价格

2016/2/4 Researchers at University of Saskatchewan in Canada have found a cheap, fast, and environmentally-friendly way to extract gold from materials while producing re-usable waste — a technology that might

获取价格

2019/3/12 In the present chapter, we introduce the adsorptive recovery of gold from. printed circuit boards (PCBs) of spent mobile phones, a typical e-waste, and actual. gold ore, a primary resource of

获取价格

Various methods such as gravity concentration, flotation, panning, pyrometallurgy, cyanidation etc are available for the extraction of gold metal from its ores. Amongst these methods, cyanidation is the most common

获取价格

高达$3返现 Gold Extraction and Recovery Processes - Free download as PDF File (.pdf), Text File (.txt) or read online for free. Gold minerals, Gold extraction methods, Refractory ore processing, Gold recovery from solution,

获取价格

Gold can be found in complex sulfide minerals in particular, pyrite and arsenopyrite (Asamoah et al, 2018). In refractory gold ores, the gold is highly encapsulated in the sulfide matrix and pre-treatment is an important process to recover gold from the sulfide minerals. The sulfide minerals interfere with recovery of gold thus it is imperative

获取价格

2023/3/15 In this research, the recovery of gold and silver, as well as secondary metals from a mineral concentrate using a native consortium through a bioleaching process was evaluated.

获取价格

waste activated carbon at Stawell Gold Mines which can profitably recover the 150 to 200 grams of gold per ton of waste carbon whilst minimising carbon dioxide emissions. An ideal process would allow the gold to be recovered on site, however, there is also merit in a process which could reduce the cost of transport and/or processing by increasing

获取价格

2012/3/1 Download full-text PDF Read full-text. Download full-text PDF. Read full-text. Download citation. Copy link Link copied. ... This is the initial step in a gold recovery process in which all acces-

获取价格

2021/4/1 In addition, the total recovery of gold in the whole process is 98.06%, which is lower than the total recovery of gold by the thiourea leaching and pyrite enhanced chlorination roasting, this may be due to a little gold lost in the two stages roasting process. Download: Download high-res image (399KB) Download: Download full-size image; Fig. 12.

获取价格

1997/1/1 PDF A series of processes has been developed to recover the gold from electronic scrap containing about 200~600 ppm Au. ... A process for the recovery of gold from processed gold-plated printed ...

获取价格

2021/6/7 A novel and sustainable technology to recover gold from thiosulfate medium using ionic liquids, i.e., Cyphos IL 101 (Cy IL 101) and Cyphos IL 102 (Cy IL 102) diluted in toluene, has been developed. Gold was extracted into the ionic liquid phase as [{P66614+}3{Au(S2O3)23–}] and stripped using NaCl solution. The recyclability of ionic

获取价格

2024/2/8 Chemical composition of e-waste. We begin with chemical analyses of an end-of-life CPU, a core component of a wide range of electronic devices and thus in e-waste (Fig. 1a and Supplementary Fig. 2 ...

获取价格

Scalable and selective gold recovery from end-of-life electronics Heng S 1, Y C 1,2, S G 1, Y Wang 1, Jiaz Cao 1, ... yet up t.He we show a photocatalytic process that allows for

获取价格

2021/8/19 Electronic e-waste (e-waste) is a growing problem worldwide. In 2019, total global production reached 53.6 million tons, and is estimated to increase to 74.7 million tons by 2030. This rapid increase is largely fuelled by higher consumption rates of electrical and electronic goods, shorter life cycles and fewer repair options. E-waste is classed as a

获取价格

2020/11/11 Gold is a highly required material for a wide range of personal and industrial applications. The high demand for gold, together with the shortage of natural resources and high pollution potential of wastes generated during mining and ore processing activities led to search for alternative sources of gold. A possible source is represented

获取价格

1994/8/1 The gold may then be recovered by electrowinning or reduction.Other work on a mixed-metal intensive cyanide leachate type solution (700 ppm Au, 400 ppm Ag, 200 ppm Cu, 150 ppm Ni, Fe, and Zn) has ...

获取价格

2023/10/31 Electronic waste (e-waste) has emerged as a valuable secondary source of metals, including precious metals (PMs), surpassing those found in natural ores. The objective of this study is to explore the use of cellulose-based adsorbents, specifically dithiocarbamate-modified cellulose (DMC) and proline-incorporated DMC with epoxy

获取价格

waste copper slag. This process is simpler than conventional pyrometallurgical process as the addition of any external collectors are not required.47 Hydrometallurgy Metal separation and recovery using hydrometallurgical processes have lower capital cost and environmental impact than pyrometallurgy, and offer greater scope for selective metal

获取价格

2020/11/11 Gold is a highly required material for a wide range of personal and industrial applications. The high demand for gold, together with the shortage of natural resources and high pollution potential of wastes generated during mining and ore processing activities led to search for alternative sources of gold. A possible source is represented

获取价格

1994/8/1 The gold may then be recovered by electrowinning or reduction.Other work on a mixed-metal intensive cyanide leachate type solution (700 ppm Au, 400 ppm Ag, 200 ppm Cu, 150 ppm Ni, Fe, and

获取价格

2023/10/31 The increasing global demand for precious metals (PMs), such as gold (Au), silver (Ag), palladium (Pd), and platinum (Pt), has led to the exploration and utilization of secondary sources due to the depletion of primary sources, global economic growth, and technological advancements [1,2,3,4].One significant secondary source of metals,

获取价格

waste copper slag. This process is simpler than conventional pyrometallurgical process as the addition of any external collectors are not required.47 Hydrometallurgy Metal separation and recovery using hydrometallurgical processes have lower capital cost and environmental impact than pyrometallurgy, and offer greater scope for selective metal

获取价格

Outline of the Process. The gold refining technique described here is the rather ancient wet chemical method whereby the gold-bearing scrap is dissolved in aqua-regia. m is gold solution is then filtered and the jewelers bench dirt, sandpaper grit, grinding wheel grains and similar material remains on the filter as a solid sludge, together with ...

获取价格

2024/1/13 One common challenge during the fine gold recovery process is the loss of gold particles due to various factors. These may include improper equipment setup, incorrect techniques, or inadequate understanding of fluid dynamics. Regularly monitor the separation process, make necessary adjustments, and continuously refine techniques to

获取价格

2021/4/1 Cyanide-refractory ores constitute 30 % of the world’s gold mineral resource base. With the global decrease in the availability of high-grade and free-milling ores, low-quality ores, including ...

获取价格

2019/2/27 Currently, the SART process has demonstrated to be the best option to treat gold-copper ores using cyanide, due to its capability to recover cyanide and produce a saleable copper product.

获取价格

2015/8/6 What is cyanide and why do we need cyanide-free gold leaching process? Cyanide (CN –) has been used since 1889 to recover gold from hard rock. As sodium cyanide (NaCN), it reacts with gold, oxygen (O), and water (H 2 O) to form a gold cyanide complex (Na [Au(CN) 2] ) and sodium hydroxide (NaOH). The chemical reaction dubbed

获取价格

2022/3/1 Microorganisms can be applied at different stages of the gold recovery process. During the leaching stage, they play a key role by producing lixiviants (thiosulfate, cyanide and iodine) that dissolve gold (Amachi, 2008; Kaksonen et al., 2014; Reith et al., 2007). A case in point is cyanide-producing bacteria.

获取价格

2020/11/1 The addition of 15 g/L of activated carbon to the pregnant leach solution (PLS) could provide 100% recovery of gold from solution onto activated carbon, i.e. holistic recovery of 90%.

获取价格

2020/3/18 A process flow sheet for the extraction and recovery of HNO 3 and Au from the gold-bearing aqua regia solution is presented in Fig. 7. As seen in the figure, both HNO 3 and Au can be extracted over other metals /components (HCl and Cu, Ni, Co, Zn) by using TBP at room temperature.

获取价格

2019/12/26 Haoyu Li a State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization, Kunming University of Science and Technology, Kunming, China;b Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming, Yunnan, China;c Key Laboratory of Unconventional Metallurgy,

获取价格

The complete recovering process only requires muriatic acid, hydrogen peroxide and bleach. Image source: sreetips. Move on to the Next Page video: How To Recover Gold From Computer Scrap with Household Chemicals. Next Page. Pages: 1 2.

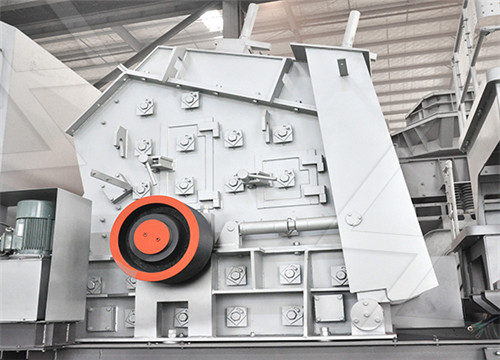

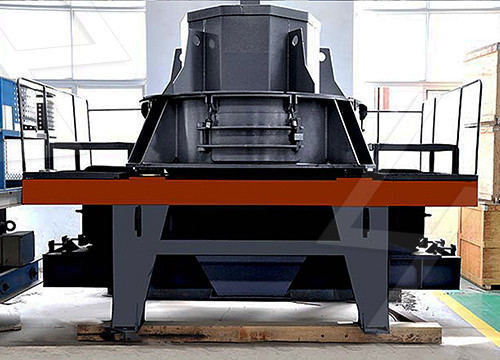

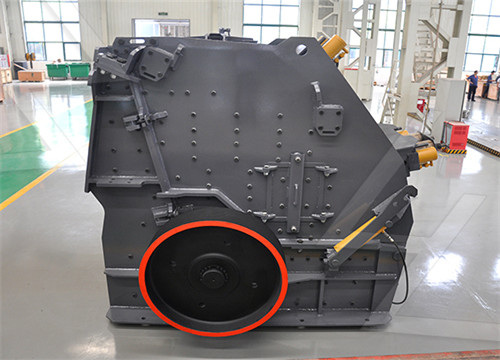

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين