Bornite (Cu5FeS4), covellite (CuS) and chalcocite (Cu2S) are important sources in the world, and many ore bodies also contain some malachite (CuCO3.Cu(OH)2), azurite

获取价格

Au extraction process route used for treating the Eburnean Tectonic province RGO is schematically shown in Figure 2.Comminution is first performed on the run-of-mine (ROM) to reduce the particle ...

获取价格

2017/9/7 Metallurgical processing of metalliferous ores in general and gold ores in particular, consists essentially of three stages, often colloquially referred to as: Bashing (crushing); Mashing (grinding); and.

获取价格

Many modern gold plants incorporate gravity circuits as part of their overall flowsheet, and it is estimated that about 10% of the new gold produced each year is recovered by this

获取价格

2017/8/1 The governing method for gold ore processing has been cyanide leaching since the late 19th century (Marsden and House, 2006). After decades of active

获取价格

The average annual outdoor temperature is 2.1 °С. Winter normally lasts for 5 months, and some years the winter period can be longer or shorter by 0.5 month. The coldest winter

获取价格

2019/8/22 Gold flotation. Flotation process is widely used for lode gold processing. In most cases, the flotation method has a good effect in sulfide-containing gold ore with

获取价格

2015/9/15 Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and

获取价格

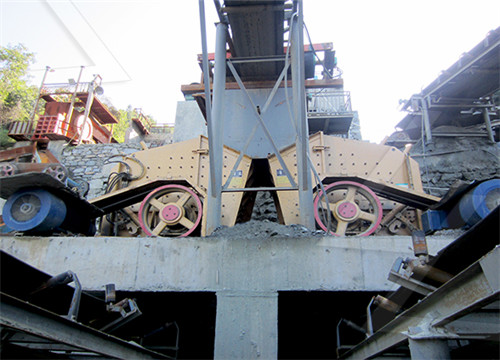

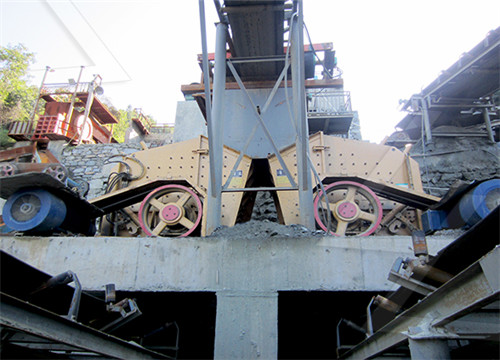

2022/5/19 01 Step #1: Crushing and Screening. The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll

获取价格

2013/1/2 Cyanide is a lixiviant, or reagent that is used to leach, often in tanks, gold from a solid matrix and form a gold cyanide complex. The gold cyanide complex is then extracted from the pulp or slurry by

获取价格

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the

获取价格

Download scientific diagram -Block diagram for gold extraction from ore from publication: Study on attrition of carbon particles during regeneration of activated carbon Cyanidation technology ...

获取价格

2016/3/8 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants. Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling

获取价格

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any process that

获取价格

2016/1/23 EXAMPLE . In our Gold Process Description EXAMPLE, the ore will be received by the crushing plant initially by rail haulage from the ABC Zone and later by truck from the DEF Zones.The 350 tonne live capacity coarse ore bin is sufficient for train or truck load surges and provides approximately five hours storage of ore, permitting 1 shift of

获取价格

2015/8/26 This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process. Starting from either open-pit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore). Having a quick look now at how porphyry ores

获取价格

of high-grade ore per year for 8 years. The deposit contains 0.12 ounces of gold per ton of high-grade ore and can be acquired at a cost of $10 per ton of ore (cost of mining ore at site). A sodium cyanide process is used to extract the gold from the ore, and various other processing techniques are used to produce 99.9% pure gold bullion from ...

获取价格

Gold processing - Mining, Concentrating, Refining: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by

获取价格

Pursuing precious metals has long been rooted in human history, with gold processing standing as a testament to our evolving mastery over the natural world. The transformation of gold from raw ore to a refined state of brilliance is not merely a matter of aesthetics but an intricate ballet of ore preparation and sophisticated chemical interactions. . Delving

获取价格

C s ∞ represents the ideal residual gold grade in the ore after the leaching operation, which is a function of the average particle diameter d̅ of gold ore (9) where r Au and r CN are the ...

获取价格

2019/8/22 Gold processing description from gold geology mineral property to how to extract gold from rock and placer deposit, related gold processing plant flow chart and layout design.

获取价格

2024/3/10 The gold ore CIP processing method, that is, the carbon slurry method for extracting gold, is an important type of modern gold extraction technology. Its core is to use activated carbon’s strong ...

获取价格

Multotec's Gold Industry Flow Sheet. We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

获取价格

C s ∞ represents the ideal residual gold grade in the ore after the leaching operation, which is a function of the average particle diameter d̅ of gold ore (9) where r Au and r CN are the ...

获取价格

2019/8/22 Gold processing description from gold geology mineral property to how to extract gold from rock and placer deposit, related gold processing plant flow chart and layout design.

获取价格

2024/3/10 The gold ore CIP processing method, that is, the carbon slurry method for extracting gold, is an important type of modern gold extraction technology. Its core is to use activated carbon’s strong ...

获取价格

Multotec's Gold Industry Flow Sheet. We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

获取价格

2021/11/5 High gold price has increased the focus on the development of refractory gold ores and concentrates. The launch of the compact Elution and Goldroom plant has completed Metso Outotec’s run-of-mine ore to doré process flowsheet and at the same time enabled us to provide a leading standardised solution for the forming of concentrated

获取价格

In the process of cyanidation of refractory gold ore containing arsenic, the wrapped gold cannot bond with a cyanide solution, which reduces the extent of gold extraction [2]. In addition, the ...

获取价格

extraction of gold from these ores is of particular impor-tance for all gold-mining and processing countries in the world [3], since the reserves of placer gold are depleted, oxidized ore is easily processed and the strategic needs to increase the size of difficult-to-process ores, while it should be kept in that reserves of these ores make up ...

获取价格

In a typical pyrytic gold ore, the gold is encapsulated within an iron sulfide crystal structure. Highly oxidized ores generally do not respond well to flotation. Advantages of the flotation process are that gold values are generally liberated at a fairly coarse particle size (28 mesh) which means that ore grinding costs are minimized.

获取价格

2015/10/1 A simplified schematic drawing of copper flotation flowsheet. Run-of-mine open pit ore will be crushed in a gyratory crusher. The crushed ore will be processed by means of semi-autogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate. The concentrate will be

获取价格

Take the follow 6 steps for help you design and build a high efficiency CIP or CIL gold processing plant to extract gold from the gold ore. 1. The concept of CIP or CIL gold processing plant 2. The application of CIP or CIL gold processing plant 3. Confirm the capacity 4. Design the flow chart 5. Purchase the equipment 6. Installation and operation

获取价格

You can easily edit this template using Creately. You can export it in multiple formats like JPEG, PNG and SVG and easily add it to Word documents, Powerpoint (PPT) presentations, Excel or any other documents.

获取价格

The flowsheet for the treatment of high-grade gold ores involves utilising proven processing paths. The flowsheet may be divided into four basic steps (Refer to Fig 1). 1. Crushing and grinding 2. Gravity concentration ... Fig 2: Gold Ore – Recovery Yield Curve Fig 3: Gold Ore – Grade Yield Curve Gold Grade Yield Curve 0 100 200 300 400 500 ...

获取价格

---Diamond Processing Plant---8TPH Diamond Mining Process in Angola 18TPH Alluvial Gold Diamond Mining Process in Angola 50TPH Alluvial Diamond Mining Process in Central African 50TPH Diamond Extraction Process Flow Chart 60TPH Alluvial Diamond Extraction Process in Venezuela 75TPH Diamond Dense Medium Separation Process

获取价格

A novel porous gold polymer composite was prepared by the functionalization of a glycidyl methacrylate-based copolymer (pGME) with ethylene diamine (pGME-en), and activation by gold (pGME-en/Au ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين