Pyrometallurgy is a branch of extractive metallurgy. It consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable metals. Pyrometallurgical treatment may produce products able to be sold such as pure metals, or intermediate compounds or alloys, suitable as feed for further processing. Examples of elements extracted by pyrometallurgical processes incl

获取价格

2021/1/26 Modern pyrometallurgy looks much different from ancient. ... cesses and equipment allowed for easier extraction of met als from. ... explained why aluminum, iron, and titanium are among the last.

获取价格

2019/4/11 In pyrometallurgical process, Al- and Si-bearing minerals in iron and aluminum ores are easily transformed into sodium aluminosilicates in the presence of

获取价格

2020/10/31 This leads to a high oxygen and aluminum content in the alloy. With a melt separation with high basicity slag treatment, the Al 2 O 3 inclusions can be effectively removed from the alloy melt, and the slag

获取价格

2022/11/1 Because aluminum is highly recyclable and durable, nearly three-quarters of the aluminum produced in China is recycled. Furthermore, AD produced annually by

获取价格

2016/4/25 The extraction of metals from a primary or a secondary resource is achieved by pyrometallurgy and hydrometallurgy. Currently, most of metal production

获取价格

2019/4/11 In pyrometallurgical process, Al- and Si-bearing minerals in iron and aluminum ores are easily transformed into sodium aluminosilicates in the presence of Na2O constituents, which alters the leaching behaviors of Al2O3 and SiO2. It was confirmed that sodium aluminosilicates with different phase compositions synthesized at various

获取价格

2021/1/26 Pyrometallurgy has existed in one form or another for several thousand years. From paintings on the walls of ancient Egyptians, we know that the idea of heating metals (such as gold) to shape them existed even in ancient times [].It is a massive production industry with 16.5 million metric tons of copper by pyrometallurgical

获取价格

Aluminium extraction is based on the fuse salt electrolysis. (Slide 23-31) While 'separation is the essence of metal extraction'. The scope extends beyond separation. ... Pyrometallurgy Operation, purpose and basis of separation Calcination removal of H20/CO2 decomposition Roasting conversion of form, chemical reaction

获取价格

A problem with pyrometallurgy is that metals cannot be recovered individually but as metal alloys [39]. Due to the vigorous reducing activity of lithium and aluminum, it is difficult to recover during the reduction smelting process, and the slag-forming agent enters the slag phase, which requires further treatment [36].

获取价格

2023/11/1 Aluminum is an important lightweight and high-value metal that is widely used in the transportation, construction, and military industries. ... This review briefly describes the distribution and proportions of bauxite deposits in China, the Al extraction process, and the hazardous solid waste that is generated. ... including the

获取价格

2022/9/7 As highlighted by many authors, 179,180,181 the simple remelting of aluminum and its alloys in reverberatory or rotary furnaces requires only 5% of the energy need of the primary extraction from the Hall–Héroult process. 182 There are many unwanted elements upon aluminum re-melting such as Cu, Mn, Fe, as well as C and H

获取价格

The Preparation of Aluminum. The preparation of aluminum utilizes a process invented in 1886 by Charles M. Hall, who began to work on the problem while a student at Oberlin College in Ohio.Paul L. T. Héroult discovered the process independently a month or two later in France. In honor to the two inventors, this electrolysis cell is known as the

获取价格

2023/6/30 To understand the basic principles of copper extraction from ores; To understand the basis of it s purification by electrolysis; To identify some common uses of copper; Extracting copper from its ores. The method used to extract copper from its ores depends on the nature of the ore. Sulfide ores such as chalcopyrite (\(CuFeS_2\)) are

获取价格

2023/3/28 Lithium extraction with process 1 Process 1 for LCO cathode. The recycling process 1, shown schematically in Fig. 1a, was applied for the LiCoO 2 material. XRD patterns in Fig. 2 show that ball ...

获取价格

2023/6/30 Introduction. Aluminum is too high in the electrochemical series (reactivity series) to extract it from its ore using carbon reduction. The temperatures needed are too high to be economic. Instead, it is extracted by electrolysis. The ore is first converted into pure aluminum oxide by the Bayer Process, and this is then electrolyzed in solution in

获取价格

2022/8/12 Antimony is classified as a critical/strategic metal. Its primary production is predominated by China via pyrometallurgical routes such as volatilization roasting—reduction smelting or direct reduction smelting. The performance of most of the pyro-processes is very sensitive to concentrate type and grade. Therefore, technology

获取价格

Electrowinning of copper. Non-ferrous extractive metallurgy is one of the two branches of extractive metallurgy which pertains to the processes of reducing valuable, non-iron metals from ores or raw material. Metals like zinc, copper, lead, aluminium as well as rare and noble metals are of particular interest in this field, while the more common metal, iron, is

获取价格

An analytical review of scientific literature devoted to assessing the efficiency of recycling of mining and metallurgical wastes showed that they are mainly focused on solving such problems as ...

获取价格

Introduction and the Significance of Electrometallurgy. J.W. Evans, in Reference Module in Materials Science and Materials Engineering, 2016 Abstract ‘ Electrometallurgy ’ is the group of technologies used for extraction of metals from solutions, including molten salt solutions (‘electrowinning’), or for the purification of metals by electrochemical dissolution

获取价格

2022/8/12 Antimony is classified as a critical/strategic metal. Its primary production is predominated by China via pyrometallurgical routes such as volatilization roasting—reduction smelting or direct reduction

获取价格

Electrowinning of copper. Non-ferrous extractive metallurgy is one of the two branches of extractive metallurgy which pertains to the processes of reducing valuable, non-iron metals from ores or raw material. Metals like zinc, copper, lead, aluminium as well as rare and noble metals are of particular interest in this field, while the more common metal, iron, is

获取价格

An analytical review of scientific literature devoted to assessing the efficiency of recycling of mining and metallurgical wastes showed that they are mainly focused on solving such problems as ...

获取价格

Introduction and the Significance of Electrometallurgy. J.W. Evans, in Reference Module in Materials Science and Materials Engineering, 2016 Abstract ‘ Electrometallurgy ’ is the group of technologies used for extraction of metals from solutions, including molten salt solutions (‘electrowinning’), or for the purification of metals by electrochemical dissolution

获取价格

2024/4/1 Pyrometallurgy is based on the use of high temperatures to recover valuable metals. ... if the objective is to achieve effective separation between the active material and the aluminum foil, the most cost-effective energy treatment is incineration. ... These attributes translate to elevated recovery efficiency and substantial metal

获取价格

General Principles of Production of Metals by Pyrometallurgy In pyrometallurgy, metals are extracted by converting sulfides into oxides and then reducing oxides into metals, using carbon or carbon monoxide as reducing agents. The reactions for lead, zinc, and iron are given below. The reader is cautioned that the following chemical reactions are

获取价格

2023/8/3 Pyrometallurgy is the extraction and purification of metals by heat-based methods. It entails the heat treatment of minerals, metallurgical ores, and concentrates in order to cause physical and chemical alterations in the materials, allowing for the recovery of valuable metals. ... factories for the electrolytic reduction of aluminum are also ...

获取价格

2013/7/18 More metals became known and new techniques were introduced for their extraction. Among these, metallothermic reactions became prominent in the 19th century immediately after the discovery of the electric current and its use to liberate the alkali metals from their salts. ... they were used to produce aluminium from alumina that resisted all ...

获取价格

2022/11/20 Finally, solvent extraction is the most important of the separation and purification methods. Solvent extraction provides the advantages of a high recovery rate, a mature process application, and environmental friendliness compared to other technologies. However, current solvent extraction applications are dependent on acid-base conditions.

获取价格

In the processing of metal ores to metals which are in common industrial use – steel, aluminium, nickel, copper, titanium, and many others, metal oxides or other compounds are converted to the metallic state by a reduction process and separated from gangue materials before or after reduction. ... Two major metallurgical routes to produce ...

获取价格

Pyrometallurgy, extraction and purification of metals by processes involving the application of heat. ... The aluminum takes the oxygen from the manganese dioxide and reduces the manganese dioxide to metallic manganese and creates aluminum oxide and a lot of heat. 3MnO +2Al 3Mn+Al2O3

获取价格

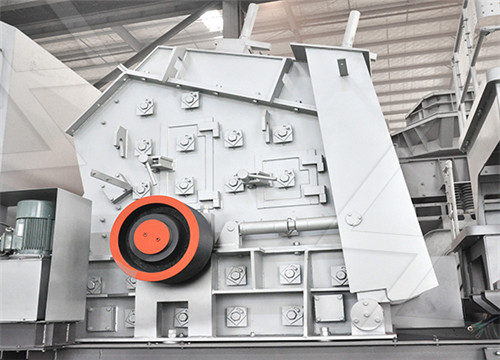

2023/2/10 Using pyrometallurgy, extraction of Au and Cu is carried out from waste electronic gadgets (Ilyas et al., 2013; Sun et al., 2016; Islam et al., 2020). In pyrometallurgy, smelting is a vigorous process that includes modern equipments like Noranda reactor system, Outokumpu flash smelting, and continuous smelter.

获取价格

2020/6/18 Considering that the low recovery efficiency and the massive loss of valuable metals by the traditional pyrometallurgical process smelting low‒nickel matte. Therefore, this paper focuses on ...

获取价格

2023/2/5 While hydrometallurgy involves using water for the extraction of metals, pyrometallurgy is a heat-based extraction and purification ... such as cobalt and nickel, can be recycled. Lithium, aluminum, and manganese end up in the slag and are not recovered, as this is not economically feasible. Is hydrometallurgy a better option for

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين