2023/11/1 Mineral processing methods such as hand sorting, jigging, electrostatic, and magnetic separation were utilized in the past as part of the process flowsheet for

获取价格

2024/6/5 Step-by-Step Barite Ore Processing. 1. Crushing and Screening: - Crushing: The extracted barite ore is transported to a primary crusher where it is broken down into smaller pieces. - Screening ...

获取价格

2024/8/14 Barite ore crushing and washing. In the crushing and washing process of barite ore, efficiency is key. If the barite ore contains a large amount of mud, the ore washing machine needs to be added.

获取价格

2023/3/20 In an efficient barite processing plant, barite ore needs to go through processes such as crushing, screening, and beneficiation. Each process will vary slightly based on the above factors. Barite Crushing

获取价格

Barite Beneficiation Process. Barite, a mineral composed of barium sulfate (BaSO4), is brittle with large tubular crystals. Barite beneficiation aims to remove impurities and improve the properties of barite for its intended

获取价格

Barite is a mineral composed of barium sulfate, BaSO4. It is usually colorless or milky white, but can be almost any color, depending on the impurities trapped in the crystals during

获取价格

Barite Mineral Processing. and. Recovery. Barite is a mineral composed of barium sulfate (BaSO4) and is a highly sought-after commodity. It is unusually heavy for a non-metallic mineral, and its high specific gravity

获取价格

2024/8/14 1. Gravity separation. The process has the advantages of simple equipment, good stability, no beneficiation agent, low cost, and less environmental pollution.The barite gravity separation method is mainly

获取价格

2. Barite is a strategic non-metallic mineral resource, which occupies an important position in national economic and social development. This paper briefly describes the distribution,

获取价格

During barite mineral processing, flotation processes are required to concentrate finely ground barite ore, utilizing a rougher-cleaner flowsheet design. Barite can be efficiently floated with Arkema’s custom flotation

获取价格

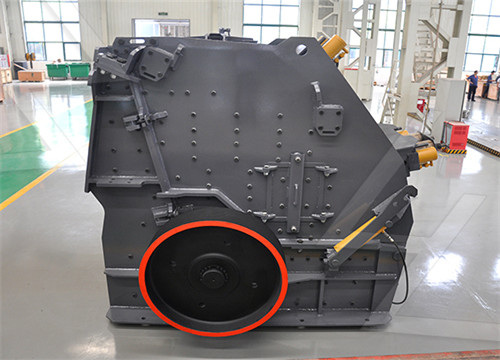

2023/9/5 The process involves crushing and grinding barite ore to reduce the desired size. It mainly involves using jaw crushers, impact crushers or cone crushers to reduce the size of barite raw material. After

获取价格

2024/4/1 The barite type ore is composed of banded barite, fluorite, bastnaesite, magnetite, and hematite (Fig. 4 g and h, Fig. 8). In addition, magnetite and hematite show veins crosscutting the barite, fluorite, and bastnaesite (Fig. 8). Barite is the main mineral with the abundance of approximately 20 %–65 %.

获取价格

why kayden’s barite recovery process is successful: Kayden’s barite and polishing centrifuges have adjustable pool plates, which combined with the VFD panel allowing the technician to make multiple adjustments to optimize the amount of barite recovered.

获取价格

2021/8/4 Barite Processing ♦ Crushing process Barite is fragile and breakable, so during crushing process we recommend jaw crusher to avoid generating plenty of powder. The raw materials can get better crushing effects through one stage crushing by jaw crusher. ♦ Screening process The particle size of crushed barites is not even, and the ore

获取价格

2024/8/14 Barite ore crushing and washing. In the crushing and washing process of barite ore, efficiency is key. If the barite ore contains a large amount of mud, the ore washing machine needs to be added. Commonly used log washers and spiral sand washers use high-pressure water jets to remove the mud and clay attached to the barite ore,

获取价格

2023/9/5 Barite, also known as barium sulfate (BaSO4), is a mineral that has a wide range of industrial applications due to its unique properties ... Barite can replace pre-existing minerals in rocks through a process called metasomatism. In this case, barium-bearing fluids react with the minerals in the host rocks, replacing them with barite ...

获取价格

2023/4/1 The raw barite-bearing aggregates were chosen using a stratified random sampling procedure across the study site, which ensured that all probable barite-containing ores were sampled. ... This covers beneficiation and statistical modelling of the barite processing, and the application of Response Surface Methodology (RSM) in the

获取价格

Barite is a strategic non-metallic mineral resource, which occupies an important position in national economic and social development. This paper briefly describes the distribution, reserves and production of barite mineral resources in the world and China. The development of barite separation process in recent years is summarized emphatically.

获取价格

2023/6/27 This setup is a barite processing plant configured with a vibrating grizzly feeder, jaw crusher, log washer, spiral sand washer, vibrating screen, and belt conveyors. The materials under the grizzly bar of the vibrating feeder go to 2 spiral sand washers through the material guide chute, the material above the grizzly bar feed to the jaw crusher.

获取价格

JAM Group Co. is a leading barite mining, processing, and supplying company. The company operates several barite mines in Iran and is one of the largest exporters of barite in the region. ... and it is also used as a contrast agent in medical imaging procedures. It is able to absorb X-rays and CT scans differently than surrounding tissues ...

获取价格

2021/6/1 Barite is a non-metallic mineral which is simply barium sulfate (BaSO4) and is largely used by the oil and gas industry as a weighting agent in drilling mud during drilling operations.

获取价格

2018/9/17 Summary. Barite is one of the most common weighting materials used in drilling fluids for deep oil and gas wells. Consequently, the main source of solids forming the filter cake is “barite particles,” the weighting material used in drilling fluids. Barite is insoluble in water and acids such as hydrochloric acid (HCl) and formic, citric, and acetic

获取价格

Barite Process Methods. Gravity Separation: For the gravity separation of barite, the process of crushing, screening and jigging. Then the high grade (over 80%) concentrate will be produced. The jig is the main equipment for the separation and purification of barite ore, which is energy-saving, high efficiency, and environment protection. In ...

获取价格

JAM Group Co. is a leading barite mining, processing, and supplying company. The company operates several barite mines in Iran and is one of the largest exporters of barite in the region. ... and it is also used as a contrast agent in medical imaging procedures. It is able to absorb X-rays and CT scans differently than surrounding tissues ...

获取价格

2021/6/1 Barite is a non-metallic mineral which is simply barium sulfate (BaSO4) and is largely used by the oil and gas industry as a weighting agent in drilling mud during drilling operations.

获取价格

2018/9/17 Summary. Barite is one of the most common weighting materials used in drilling fluids for deep oil and gas wells. Consequently, the main source of solids forming the filter cake is “barite particles,” the weighting material used in drilling fluids. Barite is insoluble in water and acids such as hydrochloric acid (HCl) and formic, citric, and acetic

获取价格

Barite Process Methods. Gravity Separation: For the gravity separation of barite, the process of crushing, screening and jigging. Then the high grade (over 80%) concentrate will be produced. The jig is the main equipment for the separation and purification of barite ore, which is energy-saving, high efficiency, and environment protection. In ...

获取价格

2024/8/14 2. Magnetic separation. For barite ore containing magnetic iron minerals with fine particle size, strong magnetic separation is often used to separate iron-containing minerals and barite.This process has the advantages of high production efficiency, low energy consumption and less environmental pollution.

获取价格

2023/11/16 Barite crystallites were observed within 30 seconds and grew with time to form rod-shaped crystals as shown in Fig. 1b.The Raman measurements during the experiments showed the signature of pure ...

获取价格

2023/3/20 In an efficient barite processing plant, barite ore needs to go through processes such as crushing, screening, and beneficiation. Each process will vary slightly based on the above factors. Barite Crushing Process Barite is brittle and fragile, so we often use jaw crushers for primary crushing. A good crushing effect will be obtained by

获取价格

2021/12/25 Barite is a strategic non-metallic mineral resource, which occupies an important position in national economic and social development. This paper briefly describes the distribution, reserves and production of barite mineral resources in the world and China. The development of barite separation process in recent years is summarized emphatically.

获取价格

2024/8/14 When magnetic minerals (such as iron oxides) are the main gangue minerals, a magnetic separation process can be used to separate barite and gangue minerals. The resulting concentrate has a high BaSO4 content, which can be used as a requirement. Barite raw material for barium-based pharmaceuticals with very low iron

获取价格

Barite Mining and Processing. Mining and processing of barite involve several key steps. 1. Exploration and Geology. The process begins with geological surveys to identify potential barite deposits. Barite is commonly found in sedimentary rocks, often associated with other minerals like fluorite and calcite. Geologists use various tools and ...

获取价格

Many barite deposits are known worldwide, but some are uneconomic because barite can be mined more cheaply in China. Uses. By far, the principal use for barite is as a "weighting agent" in oil and natural gas drilling. In this process, barite is crushed and mixed with water and other materials. It is then pumped into the drill hole.

获取价格

2024/8/16 Rare-earth element - Processing Ores: All rare-earth ores contain less than 10 percent REO and must be upgraded to about 60 percent in order to be processed further. ... In the case of Mountain Pass bastnasite, a hot froth flotation process is used to remove the heavier products, barite (BaSO4) and celestite (SrSO4), by letting them

获取价格

2023/5/29 The processing of barite involves several steps to produce a high-quality product. Here's a general overview of the process: 1.Mining: Barite is typically extracted through open-pit or underground ...

获取价格

2010/5/20 The mixture of barite and coke powder was shaped by a laboratory extruder and the reduction process was isothermally carried out at four temperatures, ranging 850–1000 °C. The effect of extrusion process on conversion of barite was evaluated by iodometry method. Also, a modified kinetic model was used to analyze the

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين