May 1, 2024. In the dynamic landscape of mining and metallurgy, the iron ore beneficiation process stands as a cornerstone, pivotal in transforming raw ore into high-grade iron products. This ...

获取价格

2023/1/1 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore. More than 85% of the hematite ore reserves

获取价格

2024/8/14 iron ore contain high sulfur, phosphorus Beneficiation. The common processes used to remove sulfur from iron ore concentrates are flotation and roasting. At

获取价格

2020/2/8 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making.

获取价格

THE CHALLENGE. CDE undertook its largest mining project to date in late 2016, converting almost 18 million tonnes of lowgrade iron ore into saleable product for SIMEC in South Australia. SIMEC required an advanced

获取价格

2024/8/2 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high

获取价格

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of

获取价格

2021/5/20 The potential iron loss in ore beneficiation of three hypothetical ores with a rich fraction consisting of haematite containing 1% Si and 67% Fe and having a fraction consisting of 70% SiO 2 and 10%,

获取价格

Iron ore beneficiation tailings plant design, Australia Helping to deliver your project vision, we provide core services from early analysis through to complete ... redesigned wash

获取价格

2024/5/1 The evolution of iron ore beneficiation process technology underscores the industry’s commitment to innovation and sustainability, driving continuous improvement in ore processing efficiency and ...

获取价格

The presentation discusses recent growth of the Australian iron ore industry and the place of beneficiation in that growth.The changes in the beneficiation processes utilised since the start of the industry in 1966 are discussed in four stages: first generation plants - heavy media processes second generation plants - jigs and spiral processes third generation

获取价格

Metofabrik is one of India’s leading manufacturers of machinery essential for the Iron ore and silica sand washing industry. We specialise in iron ore beneficiation plants, silica sand washing plant and more. We at

获取价格

2014/3/1 Beneficiation of iron ore by flotation – review of industrial and potential applications. International International Journal of Mineral Processing 10, 183 – 204.

获取价格

2015/3/28 Processes for Beneficiation of Iron Ores. satyendra; March 28, 2015; 0 Comments ; Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing,; Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth’s crust averaging from 2 % to 3 % in sedimentary rocks to 8.5 % in

获取价格

2021/5/20 The potential iron loss in ore beneficiation of three hypothetical ores with a rich fraction consisting of haematite containing 1% Si and 67% Fe and having a fraction consisting of 70% SiO 2 and 10%, 15% and 20% Fe. In this calculation, the poor fraction is discarded and the iron loss is presented per ton of DR-pellet feed.

获取价格

Efficiently remove silica, alumina, clay, and other contaminants from your feed material to increase the Fe value in the final ore. Our iron ore beneficiation projects have increased the Fe content from 43% in the feed to above 60% in the final iron ore product, ensuring increased efficiencies in steel production for our customers.

获取价格

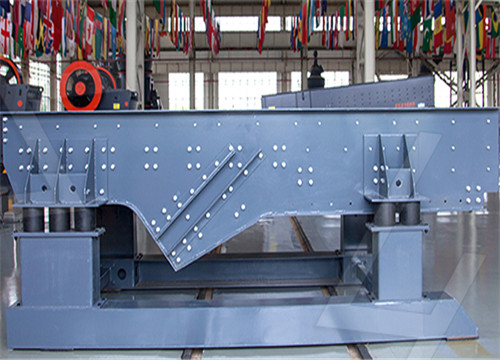

Our modular beneficiation systems have been proven over the years across the countries helping our customers maximise the quality and value of their ores. Feed point efficiency The feed hopper features an integrated belt feeder to ensure the efficient transfer of material from the hopper to the next stage of processing.

获取价格

2018/10/4 Magnetic Separation and Iron Ore Beneficiation. Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron. ... This cleaning occurs even though the variation in force due to the alternating poles within the drum does not produce the same degree of particle motion on the drum as is seen in the ...

获取价格

2021/7/2 Keeping the above characteristics in view, several west coast lateritic bauxite mines of India employ dry crushing−screening process to bring down silica content from the metallurgical grade bauxite [].Recently, a bauxite mine of Guinea known as AGB2A has also adopted the dry beneficiation procedure to cut down silica from about 7% to

获取价格

2024/3/16 Iron ore is essential in steel making; however, high-grade ores have diminished, making low-grade ores inevitable. These low-grade iron ores need further beneficiation to upgrade the iron content. Currently, traditional physical and chemical methods are utilized and are not environmentally friendly. Bio-beneficiation techniques

获取价格

2018/9/25 Several methods/techniques such as jigging, washing, magnetic separation, gravity separation, and flotation etc. are being used to enhance the iron percentage in the Iron ore and to reduce its gangue content. ... The reasons for choosing jigging for the iron ore beneficiation over other processes include (i) relatively easy

获取价格

2021/7/15 Read this blog to learn about ore washing and ore washing equipment. ... ore washing remains a common and cost-effective means of beneficiation, as water usage is enhanced by the greater use of water recovery. ... is composed of an extra-heavy steel pipe shaft with inner and outer renewable and reversible abrasion-resistant hard

获取价格

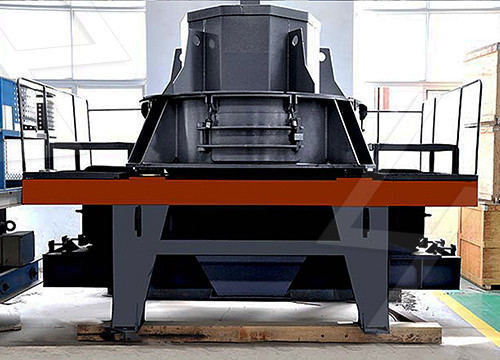

2022/3/8 This setup is for the iron ore process, the size range of the iron ore is 0-230mm, main machines as below:Hopper+vibration feeder (with grizzly bar)- jaw cru...

获取价格

2024/3/16 Iron ore is essential in steel making; however, high-grade ores have diminished, making low-grade ores inevitable. These low-grade iron ores need further beneficiation to upgrade the iron content. Currently, traditional physical and chemical methods are utilized and are not environmentally friendly. Bio-beneficiation techniques

获取价格

2018/9/25 Several methods/techniques such as jigging, washing, magnetic separation, gravity separation, and flotation etc. are being used to enhance the iron percentage in the Iron ore and to reduce its gangue

获取价格

2021/7/15 Read this blog to learn about ore washing and ore washing equipment. ... ore washing remains a common and cost-effective means of beneficiation, as water usage is enhanced by the greater use

获取价格

2022/3/8 This setup is for the iron ore process, the size range of the iron ore is 0-230mm, main machines as below:Hopper+vibration feeder (with grizzly bar)- jaw cru...

获取价格

2020/7/23 At present, iron ore of around +64% Fe is used for production of iron through blast furnace and direct reduction (IBM 2019). To produce +64% Fe from low- and medium-grade ores, crushing and washing are compulsory. During washing of iron ore, to improve the quality of lumps and fines, iron ore slimes are generated.

获取价格

From Canada’s Labrador Trough region, across India, Brazil and Africa, to Australia’s iron rich Pilbara, our teams deliver unrivalled expertise in fine iron ore beneficiation. Mineral Technologies can assist you to deliver a comprehensive range of testing, plant design, equipment development and support services across all stages of your ...

获取价格

Mineral Processing. Swapan Kumar Haldar, in Mineral Exploration (Second Edition), 2018. 13.2.4.3 In-Stream Analyzer and Process Control. Mineral beneficiation, particularly base and noble metals, is sensitive to optimum use of reagents, recovery of metals, and clean concentrate.High fluctuation of feed grade at flotation cells yields loss of metals to tailing.

获取价格

The current industrial practice of iron ore washing is oriented towards product with 2.5-3.0 A1 2 O ... Iron ore beneficiation facilities in the country are highly inadequate i.e.,

获取价格

2021/6/22 This 700TPH iron ore wash beneficiation plant in South Australia was designed to beneficiate extremely abrasive haematite held in stockpiles of low-grade iro...

获取价格

2024/8/14 The chemical formula of niobium-iron ore-tantalite is AB 2 O 6, both of which are referred to as niobium-tantalum. ... General tantalum-niobium beneficiation process. Washing operations are essential for processing ores with a high content of fines or primary mud. Australia Greenbus mine weathered pegmatite alluvial clay coarse

获取价格

2024/8/14 Diamond ore can be divided into rock ore or sand ore, and its beneficiation line equipmentmainly include: crushing, washing, screening, and gravity separation machines. Diamonds can be separated from metal elements in metal ores through the beneficiation production line, and undergo a series of refining and

获取价格

2022/10/20 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

获取价格

2024/8/2 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This

获取价格

2024/8/14 Common types of iron ore are magnetite, hematite, limonite and siderite. Among them, hematite, as a weak magnetic iron ore, has uneven particle size and high content of fine particles. Hematite ore is an important iron ore resource in my country. In the early 1960s, hematite ore was mainly processed by roasting-magnetic separation and

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين