The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts

获取价格

A complete size range, including the largest VRM available for raw grinding, ensure the ability to meet all possible capacity require-ments in a single mill even for the hardest

获取价格

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are

获取价格

In addition, the raw material grinding process will be supported by a QMR² 48/24. For the 4,000 tons per day kiln line Shiva Cement Ltd. contracted a quadropol® vertical roller mill for grinding pet coke with a QMK² 32/16.

获取价格

Grinding of cement raw material – material separation in cyclones. The cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill. For drying the material, hot gases are

获取价格

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and

获取价格

Raw Material Drying-Grinding. Drying of moisture in raw materials is required for effective grinding and subsequent handling of raw meal. This is achieved normally by ducting

获取价格

2016/10/5 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

获取价格

The raw material mill adopts high-fine sieving and grinding technology, and has a special structure of double-layer compartment device, active lining plate and grinding tail discharging device to meet the customer's

获取价格

Grinding aids (GAs) are polar chemicals introduced in cement mills in either liquid or powder form to improve on mill grindability efficiency. Studies have shown that some GAs not only help in grinding efficiency but also

获取价格

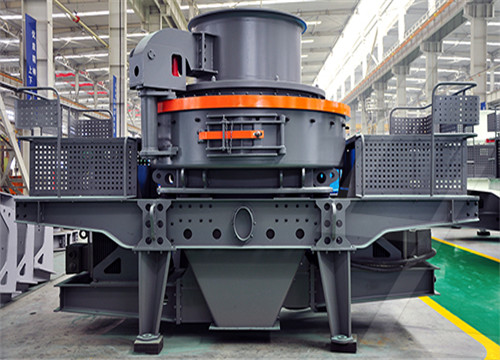

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

获取价格

2016/10/5 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals. ... This paper presents results regarding the grinding

获取价格

2012/6/1 Raw mills are used to grind the raw materials into the farine which is the semi product of clinker. It is then fed to the rotary burners which transforms it into clinker which is the semi product of cement. After the grinding process in a cement mill, the production process completes. In order to lower the cost of grinding and drying process ...

获取价格

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

获取价格

Raw mill is the grinding equipment applied in the raw material preparation process. In the wet process of cement production, raw materials should be ground into raw slurry with a water content of 30% – 40%. While in the dry process of cement production, they will be ground into dry powder in a cement raw mill.

获取价格

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plant.In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other

获取价格

2024/8/8 In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of grinding media emerges as a pivotal performance lever. This seemingly minor selection can dramatically influence the efficiency of the milling process, the quality of the output, and, ultimately, the bottom line.

获取价格

A medium-sized dry process roller mill. A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore

获取价格

For cement raw material preparation, our renowned raw mills with the proven MVR technology are perfectly suited and always adapted to the customer's particular requirements. ... Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ...

获取价格

2012/6/1 Raw mills are used to grind the raw materials into the farine which is the semi product of clinker. It is then fed to the rotary burners which transforms it into clinker which is the semi product of cement. After the grinding process in a cement mill, the production process completes. In order to lower the cost of grinding and drying process ...

获取价格

2016/11/7 In many industries the final product, or the raw material at some stage of the manufacturing process, is in powdered form and in consequence the rapid and cheap preparation of powdered materials is a matter of considerable economic importance. In some cases the powdered material may be prepared directly; for example by

获取价格

for the combined drying and grinding of very moist and sticky raw materials the aerofall mill is now used also in cement works. cement grinding in mills more than 2.8 m in diameter is performed mainly as a close-circuit operation. almost half the quantity of cement produced comes from closed-circuit grinding installations. the largest cement ...

获取价格

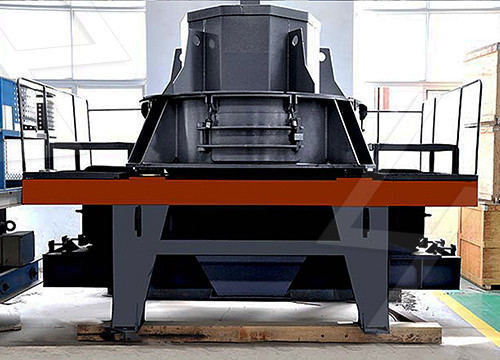

Raw materials grinding process is a first step of cement production which is has an important role in the first grinding step. Vertical Raw Mill is a main equipment that is used in grinding or ...

获取价格

This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries. Besides, the raw mill has two forms of milling, one is an open form, and the ...

获取价格

2016/11/7 In many industries the final product, or the raw material at some stage of the manufacturing process, is in powdered form and in consequence the rapid and cheap preparation of powdered materials is

获取价格

for the combined drying and grinding of very moist and sticky raw materials the aerofall mill is now used also in cement works. cement grinding in mills more than 2.8 m in diameter is performed mainly as a close-circuit operation. almost half the quantity of cement produced comes from closed-circuit grinding installations. the largest cement ...

获取价格

Raw materials grinding process is a first step of cement production which is has an important role in the first grinding step. Vertical Raw Mill is a main equipment that is used in grinding or ...

获取价格

This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries. Besides, the raw mill has two forms of milling, one is an open form, and the ...

获取价格

In cement: Grinding. The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials. The material may pass straight through the mill (open-circuit grinding), or coarser material may be separated from the Read More; cutlery. In cutlery: Cutlery manufacture

获取价格

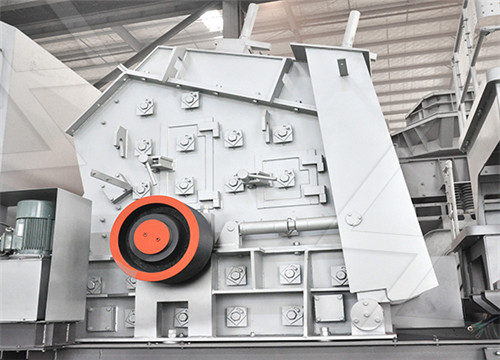

2019/10/11 The cement roller press and cement mill are used to grind the cement raw material to the required particle size and packaging. There are two types of cement mill including a ball mill and vertical cement mill. The packing machine is used to pack the finished cement product into a bag according to a certain weight.

获取价格

2013/2/26 Vertical roller mills (VRM) have become the standard for grinding raw materials in the cement manufacturing process. However, despite the fact that more than 10 years has passed since the installation of the first VRM for clinker grinding was almost completed, many cement producers are still favouring ball mills for cement production

获取价格

Raw materials in some plants are sampled automatically, and a computer calculates and controls the raw mix composition. The largest rotary kilns have outputs exceeding 5,000 tons per day. Grinding. The clinker and the required amount of gypsum are ground to a fine powder in horizontal mills similar to those used for grinding the raw materials.

获取价格

2022/11/3 HRM Raw Mill HRM,sub-brand of Sinoma, HRM vertical roller mill are new equipment designed since 1984, It through grinding rollers to roll press the materials(0-40mm)on the rotating grinding pan with pressure and grind them to be reached up to the relevant fineness. It has good advantages of high grinding efficiency,

获取价格

with the extraction of raw materials and ending with the finished product. From raw materials to cement Extracting raw materials Crushing and transportation Raw material preparation I: Storage and homogenisation Raw material preparation II: Drying and raw grinding Burning The burning of the raw meal at approx. 1,450°C is carried out

获取价格

Clinker grinding / Raw Material Grinding. VRPM can be integrate with existing Cement Mill circuit to have substantial saving in specific power consumption and increase in production capacity. We have experience of system engineering layout engineering which allows us to install the VRPM circuit within limited space in existing plant.

获取价格

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for dry-grinding the above-mentioned grinding stock.

获取价格

’s horizontal hammer mill is for pre-grinding and post-grinding in animal feed production, including pet foods and fish feed, as well as grain milling and other material size reduction processes. ... Raw material End product. End product Clear. No Results Found Related Products. No Results Found Services and training. Our services and ...

获取价格

The raw mix is produced in a raw mill by grinding the raw materials together to a fine powder. How long does it take to grind raw materials in a raw mill? The time taken to grind raw materials in a raw mill depends on various factors, including the size of the raw materials and the type of grinding plate and rollers used.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين