Experience. Innovation. Results. Gyratory CrusherHigh Performance GY SeriesCrusherSINCE 1946: Our journey started here, with the introduction of the Andreas Impact Crusher and the beginning of , now backed. by a reference list well

获取价格

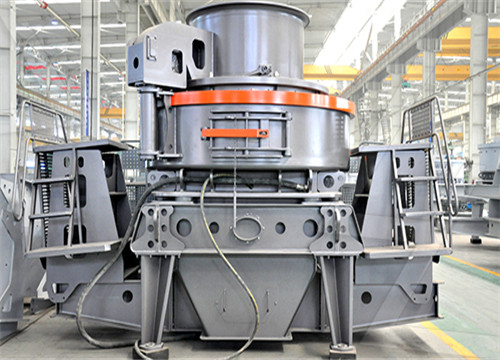

This primary crusher is designed for high performance and, at the same time, cost-effective operation with low servicing and maintenance costs. Our Gyratory Crusher Pro offers our customers high-performance crushing

获取价格

CG830i Gyratory crusher : 380 (419) 1,525 (60”) 2,700-6,000 (2,980 - 6,610) CG850i Gyratory crushers: 500 (550) 1,549 (61) 3,800-8,250 (4,180 - 9,075) The knowledge hub Over the last 150 years, we've learned a

获取价格

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

获取价格

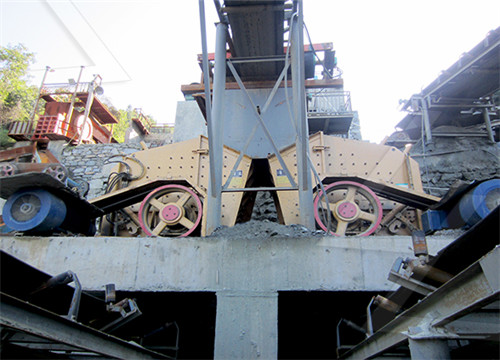

The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.

获取价格

Motor power 315 kw (430 hp) Sandvik CG810i crusher is built to be robust, reliable and efficient. ... Our range stationary gyratory crushers Stationary gyratory crushers. CG850i Capacity (by hour) 3,800 - 8,250 mtph

获取价格

But for hard rock mining, the use of gyratory crushers, ... The input pinion drive countershaft is supported by pinion bearings and powered by an electric motor. An external gearbox or belt drive arrangement reduces the motor

获取价格

Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Menu Close ... Get the maximum potential out of your size reduction process to achieve improved crushing performance and lower cost per ton. By using our unique simulation software, our Chamber Optimization ...

获取价格

Xingaonai Group Stone Crusher:X series gyratory crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies. ... 2、Long service life Low crushing cost. Super heavy-duty frame, integral heavy-duty main shaft, high-performance bearings and positive pressure dust-proof seal, the whole machine is ...

获取价格

CG830i Gyratory crusher : 380 (419) 1,525 (60”) 2,700-6,000 (2,980 - 6,610) CG850i Gyratory crushers: 500 (550) 1,549 (61) 3,800-8,250 (4,180 - 9,075) The knowledge hub Over the last 150 years, we've learned a thing or two about crushing and screening. As innovators and experts in the field, we have a deep understanding of technical and ...

获取价格

Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250-300 kW. Metso crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW. ... Lower installed cost than gyratory crushers. Can handle high abrasion with

获取价格

Our Gyratory Crusher Pro offers our customers high-performance crushing operations under toughest conditions from -40°C to 50°C - whether it is the heat of the Australian summer or the cold of the Norwegian winter.. Built for ultimate performance and easy maintenance, this hard rock crusher excels at the crushing of medium hard to hard rock

获取价格

The Gyratory Crusher TS is a high quality, modern design, durable gyratory crusher that was engineered from the ground up with an unwavering focus on performance, safety, maintenance and functionality, for the utmost reliability and efficiency in your projects. ... model, specifically designed for extreme applications, where extra motor power ...

获取价格

2023/2/28 Furthermore, the initial cost of a gyratory cone crusher can be higher than other types of crushers, which may not be feasible for all budgets. Types of Gyratory Cone Crushers. There are several types of gyratory cone crushers, each with its unique design and specific applications. The two most common types are standard and short

获取价格

rising energy costs, ensuring that a plant has the lowest total cost of ownership is vital. More sustainable technologies practices are required to make these hard, variable and low-grade ore bodies viable. 3. 4 ... world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability.

获取价格

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this presentation from MINExpo 2021, Josh Garrett, Product Manager for Crushing, explains how all TS Gyratory Crushers are built for strength, durability and the ability to adapt to

获取价格

The majority of gyratory crushers are used as primaries, i.e. they receive the initial feed from the mine or quarry. The same type of crusher with chamber modifications is used as a secondary crusher, particularly when following a large primary crusher. The fine-reduction gyratory crusher can also be used for tertiary crushing.

获取价格

2023/2/28 Furthermore, the initial cost of a gyratory cone crusher can be higher than other types of crushers, which may not be feasible for all budgets. Types of Gyratory Cone Crushers. There are several types of

获取价格

rising energy costs, ensuring that a plant has the lowest total cost of ownership is vital. More sustainable technologies practices are required to make these hard, variable and low-grade ore bodies viable. 3. 4 ... world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability.

获取价格

We have met this need with the digitally-enabled TSUV Mark 5 Top Service Gyratory Crusher, the world’s most OPEX and CAPEX-efficient gyratory crusher. In this presentation from MINExpo 2021, Josh Garrett, Product

获取价格

The majority of gyratory crushers are used as primaries, i.e. they receive the initial feed from the mine or quarry. The same type of crusher with chamber modifications is used as a secondary crusher, particularly when following a large primary crusher. The fine-reduction gyratory crusher can also be used for tertiary crushing.

获取价格

2023/5/11 Gyratory crusher comes in three basic types: fixed shaft type, slant discharge type, and central discharge type. The central discharge type (Fig. 1) is quite common.Gyratory crusher achieves discharge port adjustment and overload protection in two ways: (1) In a mechanical crusher that uses mechanical power, the upper end of

获取价格

Compared with other types of stone crushers, gyratory crushers have a higher capital cost but are often preferred for their ability to handle high-capacity operations and abrasive materials. ... The main shaft is the vertical shaft that transmits the rotary motion from the motor to the crushing head. It is made of forged or alloy steel and is ...

获取价格

Motor power 525 kw (700 hp) Sandvik CG820i crusher is built to be robust, reliable and efficient. ... Our range stationary gyratory crushers Stationary gyratory crushers. CG850i Capacity (by hour) 3,800 - 8,250 mtph (4,180 - 9,075 stph) Feed opening 1,549.0 mm (61.0 in.) Motor power 950 kw (1,275 hp) ...

获取价格

That means higher capacities, lower power requirements, and more evenly distributed wear patterns on all crusher wear parts for lower operating cost per ton. SUPERIOR® primary gyratory crushers are suitable for: The most demanding crushing applications; Stationary and semi-mobile applications; The hardest rock and ores; Surface and underground ...

获取价格

Metso's product family of primary gyratory crushers is called Superior™ MKIII primary gyratory crushers. The “MKIII” stands for the third generation of the Superior™ primary gyratory crushers has developed during over 100

获取价格

gyratory crusher Primary gyratory crusher basic concepts 4 ... • Start the crusher drive motor and allow the crusher to come to full speed • Run the crusher with no load (empty) until the return oil tempera-ture is above 65°F (18°C) ... best cost per produced ton, depending on the application and the wear rate. ...

获取价格

The gyratory crusher has capacities starting from 1200 to above 5000 t/h. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Therefore, primary gyratories require quite a massive foundation. The cone crusher is a modified gyratory crusher.

获取价格

2022/9/15 Gyratory Crusher; Principal, Construction and Working of Gyratory Crusher ... • 1. continuous in action 2. fluctuations in stresses are smaller 3. load on the motor is nearly uniform 4. power consumption per ton of material crushed is smaller and 5. requires less maintenance than a jaw crusher. • Since the capital cost of this crusher is ...

获取价格

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine Metso’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily

获取价格

Motor: Crusher weight: Power: Rotation speed: mm: mm: mm: t/h: mm: kW (Max.) r/min: t: PXZ 42-65. 1100: 900: 140-175: 1800-2850: ... Hydraulic gyratory crusher: Feed opening width: Discharge opening width: Belt conveyor capacity: Slewing crane: t/h: mm: mm: mm: t/h: ... High cost-effectiveness CITIC HIC's crushers have the capacities and ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين