and silica were obtained after spiral chute, magnetic separation and electric separation. Rajan Girija Rejith et al. [20] reported the recovery of heavy minerals from the KV and KS

获取价格

2024/1/5 Gravity Separation T ests of a Complex Rutile Ore Zhenxing Wang 1,2 , Y ongxing Zheng 1, 2, *, Xiang Huang 3 , Xiangding Wang 3 , Jieli Peng 1,2 and Zhe Dai 1,2

获取价格

2022/2/28 Gravity separation is a method in which materials/minerals are separated based upon the difference in particles density [].Water as a medium is an important factor

获取价格

Gravity separation is the most well-proven and accepted technique of concentrating minerals and has been used as a primary form of mineral concentration for centuries.

获取价格

2020/3/26 The principal beneficiation route of different rare earth-bearing minerals includes gravity separation, magnetic separation, electrostatic separation, and froth

获取价格

The complex rutile ore containing TiO 2 and ZrO 2 exhibited a high economical value. To effectively recover TiO 2 and ZrO 2 from the raw sample, a complete gravity separation

获取价格

2018/6/8 In addition, the efficiency of the rutile-slag separation and purity of the separated rutile crystals were enhanced significantly with increasing the gravity coefficient. Accordingly, the high-purity rutile

获取价格

2013/10/21 T o cite this article: Particulate Science and T echnology (2013): Gravity Separation of Silica Sands for Value Addition, Particulate Science and T echnology: An

获取价格

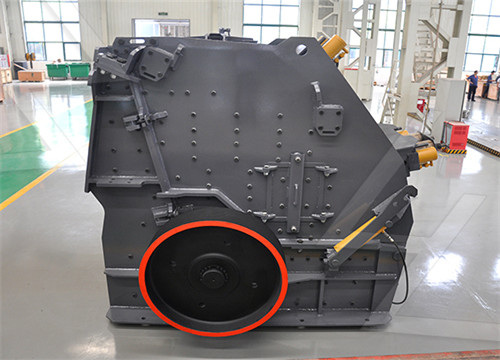

JXSC has been engaged in the production and sales of gravity separation equipment since 1985. It is a professional China manufacturer of crushers and beneficiation equipment. The types of gravity-separating machines

获取价格

gravity separation of rutile and silica Posts Related to gravity separation of rutile and silica are ilmenite and rutile iron ores ILMENITE (Iron Titanium Oxide) - Amethyst Galleries' Mineral Gallery Even though rutile is the more common mineral and has ... both minerals can be concentrate...

获取价格

Rutile (TiO2) is a red to black, ... Various methods which include magnetic, gravity and electrostatic separation as well as chemical processes, are then used to separate the sands into individual mineral species. ... from

获取价格

2024/7/11 Gravity separation is suitable for processing hard cassiterite, soft cassiterite, and wolframite in tin ore. Hard cassiterite usually contains a high tin content and a large density, significantly different from the density of waste rock so that gravity separation can achieve a good separation effect. Although soft cassiterite has a low tin ...

获取价格

1. Gravity separation In the rutile ore beneficiation process, there are two main uses for gravity separation: one is for the sorting of rutile ore with coarser grain size, another one is for the tailing work of fine-grain rutile, generally used for pre-treatment before flotation, which can effectively remove the slime and can remove part of the gangue.

获取价格

The gravity separations are simple and separate mineral particles of different specific gravity. As the density of gold mineral is much bigger than gangue mineral, for the gold mine which has gold particles people often use the gravity separation process.

获取价格

Silica sand or quartz sand, its main component is SiO2 and the content below 98.5% is called silica sand. High-purity silica sand that meets the requirements is often obtained by mineral processing and purification, including washing and desliming, magnetic separation, gravity separation, flotation and other combined processes.

获取价格

1 Description of gravity separation. Gravity beneficiation is a method of sorting ore in a certain fluid medium according to the difference in mineral density. The gravity separation process is carried out in a fluid medium, usually water, and sometimes heavy medium (heavy liquid or soliquiod).

获取价格

Gravity beneficiation process is a method to achieve separation based on differences in particle density and sedimentation speeds under gravity.Compared with other separation methods, such as flotation or magnetic separation, gravity separation can effectively concentrate heavy minerals such as zircon, rutile, and ilmenite by taking advantage of

获取价格

The separation process of rutile ore is complex, and it is difficult to obtain high-purity products through single separation. Multiple beneficiation methods are often used for joint beneficiation: such as magnetic separation, flotation, gravity separation, electric separation, etc., to obtain high-quality rutile concentrate.

获取价格

2020/5/1 High-purity rutile (TiO 2) possessing favorable dielectric properties was sustainably recovered from Ti-bearing blast furnace slag through phase transformation and super-gravity separation in this study. Firstly, the phase transformation behavior of Ti was studied, the favorable conditions for transformation from perovskite to rutile were

获取价格

2020/1/16 In such a way, this work aims through gravity separation to concentrate the mineral phase hematite. The Wilfley shaking table was used to process 500 g of the tailing. Three different materials were obtained after the separation process: hematite concentrate, middling, and gravity separation tailing (GST).

获取价格

Complete beach sand beneficiation flow mainly includes crushing, gravity separation, magnetic separation, drying and electric separation. The whole beach sand process is widely used in rutile, monazite, garnet, ilmenite and zircon sand separation plants.JXSC supports customized process flow and equipment to maximize useful mineral recovery.

获取价格

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

获取价格

2020/5/1 High-purity rutile (TiO 2) possessing favorable dielectric properties was sustainably recovered from Ti-bearing blast furnace slag through phase transformation and super-gravity separation in this study. Firstly, the phase transformation behavior of Ti was studied, the favorable conditions for transformation from perovskite to rutile were

获取价格

2020/1/16 In such a way, this work aims through gravity separation to concentrate the mineral phase hematite. The Wilfley shaking table was used to process 500 g of the tailing. Three different materials were obtained after the separation process: hematite concentrate, middling, and gravity separation tailing (GST).

获取价格

Complete beach sand beneficiation flow mainly includes crushing, gravity separation, magnetic separation, drying and electric separation. The whole beach sand process is widely used in rutile, monazite, garnet,

获取价格

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

获取价格

JXSC has more than 38+ years of experience in manufacturing mineral gravity separation equipment. Mainly includs jig separators (mineral jig concentrator), mobile jig concentrator plants, Gemini shaker tables, shaking tables (gravimetric tables, gold shaker table), spiral chutes (spiral separators), and centrifugal concentrators.It is very suitable for fine and

获取价格

2019/5/15 3.2 Gravity separation process. The density of chromite ore is slightly higher than that of its other magnetic gangue ore. Therefore, the separation of ferrochromium from other minerals can be realized by gravity separation. Use spiral chute to separate the concentrate process tailings and the scavenging process concentrate

获取价格

In a Dense Media Separation (DMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond (3.52 g/cm3), to which the diamond bearing material is added to begin the separation process of the heavier minerals from the lighter material.

获取价格

nite, rutile, zircon, quartz, magnetite, and sometimes gold. Due to its relatively high specific gravity (4.9–5.5), monazite is beneficiated along with other heavy minerals by means of gravity separation. Monazite is further sepa-rated from other heavy minerals by a series of magnetic and electrostatic separation processes. However, these

获取价格

The processing of the dredged mineral sands that separates out the heavy mineral grains from the silica sand is by using a variety of hydraulic gravity separation and magnetic equipment. The heavy mineral concentrate separated from the silica sand is then separated by electrostatic and magnetic separation to produce the end products.

获取价格

2016/5/9 Magnetic and Electrostatic Separation. Concentrates containing rutile, ilmenite, magnetite, zircon and possibly silica are sized over a vibrating screen and collected in separate storage hoppers ahead of dry processing, as each size is treated separately. Low intensity magnetic separation pulls out metallic iron and magnetite.

获取价格

2024/1/4 This complete setup is Coltan(Ta-Nb), Tin, Tungsten Washing Concentration Plant. It is configured with a Vibrating Feeder to feed raw material and remove oversized rocks.. Trommel Scrubber to wash off the sticky mud from raw ores, and screen out three size ranges, the Ta-Nb, Tin grains will be released more easily from the

获取价格

2019/5/14 The density difference between the rutile ore and its associated gangue minerals is not significant, thus it is not likely to obtain high-grade concentrates by using gravity separation process alone. A more workable way is that using gravity separator to remove low-density ore or slime partly, doing initial rutile concentration.

获取价格

Ilmenite and rutile are used in the manufacture of titanium dioxide pigment and titanium metal. Titanium dioxide pigment has high opacity and brilliant whiteness, which is principally used in paints, paper and plastics. ... The non-magnetic fraction of the WHIMS output passes to the wet gravity separation circuit to remove silica and trash ...

获取价格

2024/8/14 Each process has its advantages and disadvantages when separating limonite ore. Gravity separation offers a low-cost method but may need help recovering fine particles or efficiently removing impurities.Magnetic separation is highly selective but requires large equipment and may produce tailings with lower iron grades.Flotation has

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين