1.4 Crusher Size and Power rating: The size of a jaw crusher is usually expressed as gape x width. The common crusher types, sizes and their performance is summarized in

获取价格

to improve the efficiency of the present design. The purpose of this project is to evaluate the kinematic and static force analysis of a single toggle jaw crusher that employs the

获取价格

2017/6/30 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

获取价格

increase the factor of safety of the jaw crusher. NX-CAD software shall be used for 3D modeling of the jaw crusher and ANSYS software shall be used to do the finite element

获取价格

Figure. 2.Elevation View of Jaw Crusher II. Literature review Figure 1.Typical Jaw Crusher The working principal of Jaw Crusher is based on modern design. The crushing machine are consists of two Jaws, one

获取价格

2022/9/20 This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

获取价格

2023/2/21 A hydraulic jaw crusher is a type of jaw crusher that uses hydraulic pressure to crush materials. It has a movable jaw that is operated by an eccentric shaft, as well as a fixed jaw that is positioned opposite

获取价格

1.8 Objective of Present Work. The objective of the present work is to strive for a design and analysis of commercially available swing jaw plates (including stiffening elements),

获取价格

Average throughput rate of single-toggle jaw crusher, standard version, tolerance ± 10% Double-toggle jaw crushers Design Double-toggle jaw crushers are equipped with a

获取价格

This crusher would best suit the small recycling plants and small industries and also shopping malls for crushing small and simple materials like paint cans, soda cans, aluminium tins, machining scrap, sheet metal waste,

获取价格

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

获取价格

Components of jaw crusher In this machine, various parts (components) are inter-linked together by bolting, welding and trapping (confining) to build a functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher.

获取价格

2023/2/15 The Blake jaw crusher is the most commonly used jaw crusher in the stone crushing industry. It has a high crushing capacity, and it is easy to operate and maintain. Construction and Design: The Blake jaw crusher consists of a heavy-duty frame that carries a fixed jaw and a movable jaw. The movable jaw is pivoted at the top and is

获取价格

2024/2/5 There are mainly two types of jaw crushers: the single toggle and the double toggle (or Blake crusher). The single-toggle jaw crusher features a moving jaw suspended on the eccentric shaft. It’s known for its efficiency in crushing but tends to be more susceptible to wear because of the high motion of the jaw.

获取价格

2018/8/7 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals ...

获取价格

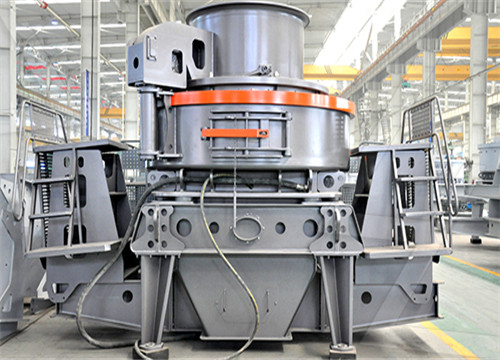

2023/2/23 Introduction. An aggregate crushing plant is a machine that processes a wide range of raw materials into high-quality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges. Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and

获取价格

Agarwalla manufactures a wide rage of quality crushing machines, ... you can customise your crusher to suit your site requirement as per your project guidelines to get the best solution. ... With proper selection and design of the system, the life of jaw plates may be enhanced. Preferably discharge height should be optimum and jaw lines should ...

获取价格

Figure. 2.Elevation View of Jaw Crusher II. Literature review Figure 1.Typical Jaw Crusher The working principal of Jaw Crusher is based on modern design. The crushing machine are consists of two Jaws, one jaw fixed and the other moving. The openings between the jaws are smaller at the bottom side and the wider at the top side.

获取价格

management. The crushing of used water bottles will also ensure that the bottles are no used beyond the shelf life of its plastic. Therefore this project will prove to be a useful asset in many ways. Index Terms - Bottle Crusher, Can Crusher, Crusher, Crusher Design, Jaw Crusher I. INTRODUCTION Plastic recycling is the process of recovering ...

获取价格

Parker have been engineering rock crushers for over 100 years and today thousands of jaw crushing machines and units have been installed around the world. ... The RockSledger down-thrust single toggle design provides a more aggressive crushing motion and subsequently higher capacities are achieved. Six standard models in the RockSledger

获取价格

A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. ... Breaking up large rocks into smaller pieces for construction projects. 2. Separating minerals from ore to extract valuable metals like gold or silver. 3. Recycling materials like glass, plastic, or rubber that would otherwise end up in ...

获取价格

JXSC, as your jaw crusher manufacturers, custom crushers for your project needs. There are many types of jaw crusher machine, and they are chosen for particular scenes based on their qualities. Each model is engineered with specific features to handle different materials and operational requirements effectively.

获取价格

2023/2/28 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industry.They are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes. The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore

获取价格

Parker have been engineering rock crushers for over 100 years and today thousands of jaw crushing machines and units have been installed around the world. ... The RockSledger down-thrust single toggle design

获取价格

A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. ... Breaking up large rocks into smaller pieces for construction projects. 2. Separating minerals from ore to extract

获取价格

JXSC, as your jaw crusher manufacturers, custom crushers for your project needs. There are many types of jaw crusher machine, and they are chosen for particular scenes based on their qualities. Each model is

获取价格

2023/2/28 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industry.They are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes. The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore

获取价格

This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes. This paper involves the process of designing the crusher considering forces required for crushing and ergonomic factor that an operator needs. The design of this machine is such that it would require optimum load to

获取价格

Size Reduction) A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue) material.Waste material can be discarded or recycled

获取价格

Fig. 1 Design of can crusher machine 1.1 Type of can crusher Fig. 2 Several tin can crusher 1.2 Crusher A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces. Crushers may

获取价格

2024/2/22 A jaw crusher is a sturdy machine that breaks down big rocks and ores into smaller pieces. It has two main parts: a fixed jaw that doesn't move and a swinging jaw that does. ... Rental jaw crushers are practical for many projects, giving you access to up-to-date equipment without a long-term commitment. ... From their tough design to their ...

获取价格

2021/5/6 A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point. The motion is, however, a more complex one than the

获取价格

2023/2/23 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush large rocks and ores into smaller pieces for further processing. A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the

获取价格

increase the factor of safety of the jaw crusher. NX-CAD software shall be used for 3D modeling of the jaw crusher and ANSYS software shall be used to do the finite element analysis of the jaw crusher. I. INTRODUCTION Jaw crusher is a machine designed to reduce large solid particles of raw material into smaller particles. Crushers are major

获取价格

What is a Jaw Crusher? As we introduced in a recent blog post about all the different types of crushing equipment available, jaw crushers are sometimes also referred to as “rock breakers,” which speaks to their brute force. They are almost exclusively used as primary crushers because they excel at breaking up some of the largest and hardest materials

获取价格

2020/5/5 D.P. Patel and K.S. Parmar "Swing jaw plate in jaw crusher machine," International Journal of Engineering Development and Research, Vol. 4, No. 1, pp. 123-127, 2016. Show more Recommended publications

获取价格

2024/4/19 The rotating shaft connects the two jaws; the moving jaw presses the material against the stationary jaw. On the contrary, Blake jaws crushers vs gyratory crushers, the bottom is where the moving jaw is pivoted in the latter type of crusher. This machine is known for its high crushing capability and its ability to handle hard types of

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين