Product features. in gear/pinion mill drives:The Metso QdX4TM Mill Drive provides the next step in the evolution of change in mill drive architecture, while allowing the system

获取价格

A complete range of gear and pinion sets, inspections, design, installation and alignment services to drive your mill’s performance Introducing a new name Metso Outotec is

获取价格

The Metso QdX4™ Mill Drive features internal torque splitting capability transmitting motor input power to the pinion shaft and equally dividing into two mill pinions. This type of torque splitting gear box technology has

获取价格

Go gearless to meet your business objetives by exceeding standard availability targets in your grinding operations. ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous

获取价格

The Quadrex Mill Drive was created in partnership with CMD and Ferry Capitain Engineering as a large mill drive solution for the mining industry. Internal torque splitting

获取价格

system to account for the inherent starting capacity of electric motors. The Incher drive power P inch is defined as 0.5 * IC engine power. Speeds are normally 1800 rpm (exact)

获取价格

tem for a new, high-capacity vertical roller mill, and explains the thinking behind the decisions made. After a summary of the most important functions of the drive for a

获取价格

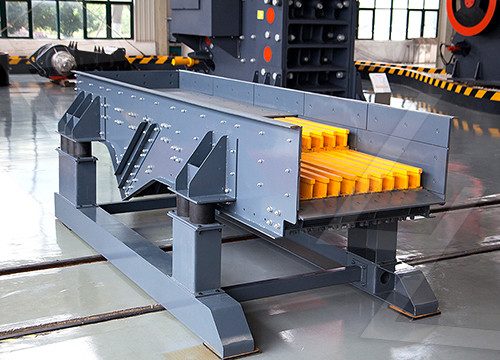

Supplied as an individual component or as a fully optimised system comprising a girth gear, mill drive gearbox, pinion and barring drive, our pinions are manufactured double ended for reversible and extended

获取价格

Presently it is possible to transmit energies of more than 3000 kW with gear and single pinion drive [84, 85, 86]. Recently, KHD Humboldt Wedag AG constructed a tube mill with gear and double pinion drive with a power

获取价格

Single-pinion drives must be able to withstand the acting forces permanently. FLENDER MDSS is a standardized gear unit that was optimized to meet the high requirements of

获取价格

» counter shaft pinion drive system for mill » crusher for oman limestone processing » used mini gold wash plant for sale in uk » design of reinforced concrete structures gambhir ; Contact Us. Tel: 86-21-58386256; Office Add: Pudong New Area, Shanghai, China. Postcode: 201201; E-mail: [email protected] Random Read

获取价格

2017/10/20 For a rack and pinion drive system, the maximum force that can be transmitted is largely determined by the tooth pitch and the size of the pinion. These systems are well-established linear drive

获取价格

Our GMD eliminates all mechanical components of a conventional mill drive system, such as ring-gear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the

获取价格

The material fed through the mill is crushed by the impact and ground as a result of the friction between the balls. The drive system can either consist of a central drive (central gear unit: helical gear unit or planetary gear unit) or a girth gear unit with pinion design (central gear unit: helical gear unit).

获取价格

2 Metso d4 TM Mill Drivesystem 7 MW 7 MW 14 MW 28 MW 7 MW 4 MW 7 MW 7 MW 7 MW 4 MW 7 MW 7 MW SAG mill 32 ft. single drive The natural progression in gear/pinion mill drives: The Metso QdX4TM Mill Drive provides the next step in the evolution of change in mill drive architecture, while allowing the system to be built with components that are

获取价格

2016/7/15 Greetings All- As the Atlas mill rebuild continues I find that the bushings on the spindle and counter shaft are worn to varying degrees. I would like to replace them and it looks like McMaster Carr has "Oil Embedded Sleeve Bearings" (often called "Oilite" bearings) that come in the sizes that...

获取价格

Mill drive gearboxes are designed to complement the girth gear to deliver cost effectiveness across the entire system; Gear cases machined from rigid housings to ensure optimum shaft alignment, reduced noise and dynamic deflections ... Simple lubrication and cooling allows the system to operate at various speeds including barring, with use of ...

获取价格

A complete range of gear and pinion sets, inspections, design, installation and alignment services to drive your mill’s performance Introducing a new name Metso Outotec is proud to announce the launch of our new rebranded offer: Metso Outotec Gears and Pinions. You can expect the same quality supported by decades of gearing and OEM expertise.

获取价格

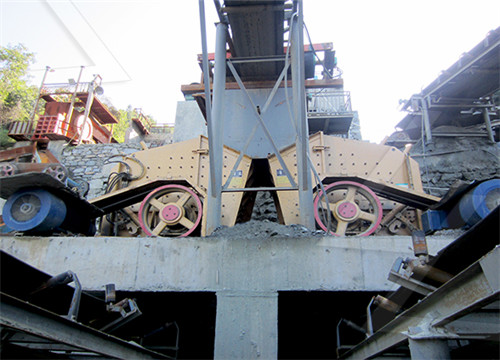

Tumbling mills are most commonly rotated by a pinion meshing with a girth ring bolted to one end of the machine (Figure 7.10).The pinion shaft is either coupled directly or via a clutch to the output shaft of a slow-speed synchronous motor, or to the output shaft of a motor-driven helical or double helical gear reducer. In some mills, electrical thyristors

获取价格

A: Large concrete surface at mill drive end, Fig. 2A, with increased tendency towards cracking. Shaft position shst, impairment of tooth contact, and risk of wear. B : Mostly common foundation block, Fig, ZB, for mill and drive unit. Risk of foundation cracking negligible. No impairment of tooth con- tact possible. 11.

获取价格

Single-pinion drives must be able to withstand the acting forces permanently. FLENDER MDSS is a standardized gear unit that was optimized to meet the high requirements of the application. For the girth gear/pinion drive, a FLENDER gear unit with input shaft on both sides from the standard range is generally used as the main gear unit.

获取价格

2023/12/11 Transmission shafts are essential engine parts for diverse applications. Read on for a detailed explanation of their design, manufacturing, and types.

获取价格

2015/7/28 Ball Mill PINION SHAFT BEARINGS. Pinion shaft bearings are of the SKF anti-friction type mounted in a common twin bearing assembly. Bearings are fixed in place so that the pinion shaft of the mill is always in alignment with the drive components. V-belt driven mills are furnished with an outboard bearing of similar construction.

获取价格

A: Large concrete surface at mill drive end, Fig. 2A, with increased tendency towards cracking. Shaft position shst, impairment of tooth contact, and risk of wear. B : Mostly common foundation block, Fig, ZB, for mill and drive unit. Risk of foundation cracking negligible. No impairment of tooth con- tact possible. 11.

获取价格

Single-pinion drives must be able to withstand the acting forces permanently. FLENDER MDSS is a standardized gear unit that was optimized to meet the high requirements of the application. For the girth gear/pinion drive, a FLENDER gear unit with input shaft on both sides from the standard range is generally used as the main gear unit.

获取价格

2023/12/11 Transmission shafts are essential engine parts for diverse applications. Read on for a detailed explanation of their design, manufacturing, and types.

获取价格

2015/7/28 Ball Mill PINION SHAFT BEARINGS. Pinion shaft bearings are of the SKF anti-friction type mounted in a common twin bearing assembly. Bearings are fixed in place so that the pinion shaft of the mill is always in alignment with the drive components. V-belt driven mills are furnished with an outboard bearing of similar construction.

获取价格

2016/10/22 The motor and pinion shafts are connected together through a flexible coupling. This drive is the most compact, resulting in minimum floor space. In cases where motors must be placed away from the mill a pilot shaft extension with flexible couplings can be provided. Ball Mill SPEED REDUCER DRIVE

获取价格

Put simply – the Pinion E-Drive System sets a new benchmark for integration. Bike Selection. 6 ADVANTAGES FOR E-BIKES WITH THE NEW PINION MOTOR.GEARBOX.UNIT . A Powerful Brushless Motor. A wear-free brushless electric motor for industrial applications made in Germany, completely redesigned to fit the

获取价格

2023/3/3 The girth gear is a large ring gear that is mounted on the exterior of the mill shell and rotates the mill shell itself. The pinion is a small gear that is mounted on the counter-shaft and meshes with the girth gear, rotating the mill shell. Together, they form a vital part of the power transmission system of the mill.

获取价格

The lifetime of a rack and pinion drive is an important consideration, especially with high duty cycle applications. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. Lubrication is critical to prevent metal-to-metal contact on the rack pinion tooth flanks.

获取价格

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills. Ball Mill Drive Options. At Orbis Machinery we offer a variety of drive options to suit your needs: Standard shaft mount reducer and belt drive; Gearwheel and pinion

获取价格

The Gearless Mill Drive system consists of the ring motor with its feeding cycloconverter, pre-installed in an E-house. It also includes the excitation rectifier, the automation sys-tem (for mill and motor) including HMI, monitoring and diagnostic system, MCC’s (for mill and drive auxiliaries),

获取价格

Internal torque splitting capability of the Quadrex Mill Drive transmits motor input power to the pinion shaft and evenly divides among two mill pinions. Since the early 1960s, this form of torque splitting gear box technology has been in use. ... To test the Quadrex Mill Drive torque dividing system under the most severe operating conditions ...

获取价格

2023/6/20 Test / E-Bike: With the Pinion E-Drive System or the Pinion MGU, there is an exciting new name in e-bike drives. As a combination of gear shift and mid-engine, it is currently unique on the market. ... the torque on the drive shaft is not directly comparable with other drives. This is why one speaks here of a "comparable drive torque of approx ...

获取价格

2015/7/28 Along the shaft that connects the motor to the pinion gear are two bearings these are the INBOARD and the OUTBOARD pinion bearings, they may be one of two types a HYDRODYNAMIC, or a ROLLER BEARING. The hydrodynamic bearing is very similar to the Hydrostatic bearing that is employed as a trunnion bearing they both make

获取价格

Presently it is possible to transmit energies of more than 3000 kW with gear and single pinion drive [84, 85, 86]. Recently, KHD Humboldt Wedag AG constructed a tube mill with gear and double pinion drive with a power input of 6700 kW (about 9000 HP) . Fig. 8.0. shows a gear cutting machine made by the MAAG-Gear Wheel Co., Zurich, Switzerland.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين