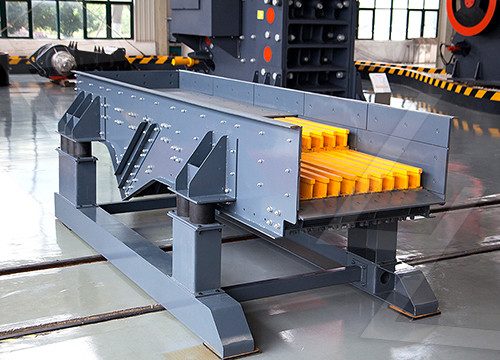

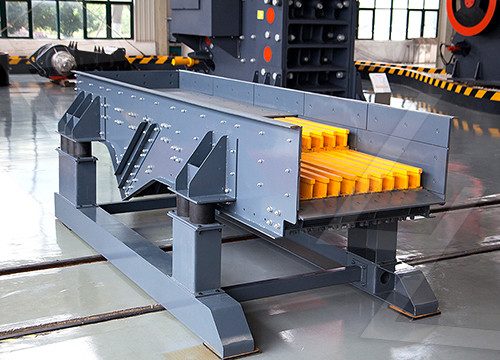

The feeding equipment is vibrating feeder. The sand making equipment includes silica sand making machine, and the cleaning equipment includes various sand washing machines and screening dehydration equipment.

获取价格

OUR proven silica sand washing solutions ensures: Guaranteed precision and maximum process efficiency – the precision of the cut points and careful attention to all material transfer points maximises retention of in

获取价格

2023/3/17 Identify the source of silica sand. Remove impurities from the silica sand. Separate silica from other minerals. Dry the silica sand. Set up a silica sand processing plant. Choose the right equipment for

获取价格

2023/8/10 A cationic collector is added to the silica sand slurry, making mica and feldspar minerals hydrophobic and forming a froth layer. The froth layer is skimmed off the surface of the flotation cell. The

获取价格

2022/6/18 It can be said that all high-quality silica sand is produced by wet beneficiation process. The commonly used purification processes for high-purity quartz sand include washing and classifying, scrubbing,

获取价格

2016/5/9 Silica sand low in iron is much in demand for glass, ceramic and pottery use, and for many of these applications clean, white sand is desired. Impurities such as clay slime, iron stain, and heavy

获取价格

Silica sand washing and desliming technology. The silica grade in quartz sand determines the quality of the final product, but the silica grade will gradually decrease as the quartz

获取价格

2023/3/17 When it comes to washing silica sand, there are several types of equipment available, including sand screws, log washers, and hydrocyclones. Sand screws are ideal for washing fine sands and

获取价格

2023/8/10 4. Silica sand drying process Dry the purified silica sand to reduce its water content to a certain level. Pack the selected silica sand for easy storage and transportation. Features of silica sand dryer:

获取价格

Hence, soda ash is a flux—a substance that can reduce the melting point of another substance. A flux such as soda ash is required for making glass because the melting point of silica sand is exceptionally high at 3,110

获取价格

2016/5/9 Silica sand low in iron is much in demand for glass, ceramic and pottery use, and for many of these applications clean, white sand is desired. Impurities such as clay slime, iron stain, and heavy minerals including iron oxides, garnet, chromite, zircon, and other accessory minerals must not be present. Chromium, for example, must not ...

2018/4/3 Ferrous foundries (those dealing with iron and steel) usually use silica sand, sometimes known as quartz sand. Silica sand has long been used in core making, so switching to using the same aggregate throughout the casting process has made the process of managing foundry supplies easier. Silica sand is the most commonly used

获取价格

When silica sand washing machine working, the electric motor drives the impeller slow rotation through the V-belt, reducer, gear reducer, sand and stones are carried into the washed tank trough the feeder tank, tumbling by the impeller, grinding each other to remove the impurities which cover on the gravel surface, while destroying the vapor ...

获取价格

100TPH Silica Sand Mining Spiral Washing Separator Recovery Process Plant Log Washer Machine, You can get more details about 100TPH Silica Sand Mining Spiral Washing Separator Recovery Process Plant Log

获取价格

2022/6/18 It can be said that all high-quality silica sand is produced by wet beneficiation process. The commonly used purification processes for high-purity quartz sand include washing and classifying, scrubbing, magnetic separation, flotation, acid leaching, and microbial leaching. #1 Washing and Classifying

获取价格

It can also be used to remove clay minerals such as mica and secondary iron from quartz sand. The most typical process is flotation with hydrofluoric acid as activator and amine cationic collector under strong acidity (pH2-3). ... Sinonine high purity silica sand washing plant can work 7x24 hours to Meet the needs of customers in large ...

获取价格

2024/8/14 Using magnetic separation in sand washing plants can improve product quality, purity and production efficiency, while achieving resource recovery and environmental protection.These advantages make magnetic separation a commonly used process in sand washing plants. It effectively removes unwanted iron particles from the

获取价格

Raw ore information in this silica sand washing project is as follows: 1. Raw sand contains 5% clay 2. Maximum feeding size of raw sand is 20mm 3. Finished silica sand size the customer need is less than 2mm 4. Raw sand contains 1% Fe2O3, customer’s requirement for removing Fe2O3 is less than 0.02% 5. Feeding capacity is 100 tons per hour 6. Over

获取价格

2020/11/2 The operation of processing silica sand deposits is basically the same as processing hard rock. In a small silica sand washing plant, a jaw crusher is used to crush the raw ore to about 25mm. In large-scale silica sand washing plant, it is better to use two-stage crushing, and impact crusher is better than jaw crusher.

获取价格

Silica sand washing and desliming technology. The silica grade in quartz sand determines the quality of the final product, but the silica grade will gradually decrease as the quartz sand particle size becomes finer, while the grade of metal minerals such as impurity minerals such as iron and aluminum will gradually increase, especially for quartz sand

获取价格

Silica Sand Mining introduces. Foundry silica sand is the quartz as the main mineral composition, particle size of 0.020 mm to 3.350 mm refractory particles, according to the mining and processing methods of different can be divided into artificial silica sand and sand washing, sand washing, selection of natural silica sand such as sand (flotation).

获取价格

Raw ore information in this silica sand washing project is as follows: 1. Raw sand contains 5% clay 2. Maximum feeding size of raw sand is 20mm 3. Finished silica sand size the customer need is less than 2mm 4. Raw

获取价格

2020/11/2 The operation of processing silica sand deposits is basically the same as processing hard rock. In a small silica sand washing plant, a jaw crusher is used to crush the raw ore to about 25mm. In large

获取价格

Silica sand washing and desliming technology. The silica grade in quartz sand determines the quality of the final product, but the silica grade will gradually decrease as the quartz sand particle size becomes finer, while the grade of metal minerals such as impurity minerals such as iron and aluminum will gradually increase, especially for quartz sand

获取价格

Silica Sand Mining introduces. Foundry silica sand is the quartz as the main mineral composition, particle size of 0.020 mm to 3.350 mm refractory particles, according to the mining and processing methods of different can be divided into artificial silica sand and sand washing, sand washing, selection of natural silica sand such as sand (flotation).

获取价格

2019/10/25 Our sand is ideal for fracking, which requires smaller sized sand to fill the cracks during the process. Our silica sand is naturally occurring and costs less than other brands. It also has a high purity (greater than 99%), exceeding purity levels of our competitors. The Characteristics of Silica and Washed Sand Silica Sand

获取价格

Scrubbing Scrubbing is the way to remove film iron and impurity minerals on the surface of quartz by mechanical force and crush these mineral aggregate. The Quartz Sand(Silica Sand) gets further purification by classification. There are two kinds of methods rob scrubbing and mechanical scrubbing.

获取价格

2024/3/5 Mining Process of Silica Sand. The mining process of Silica Sand involves sophisticated mining plants, geological assessments, and advanced technologies like 3D modeling to ensure efficient extraction and quality control. At these mining plants, state-of-the-art equipment is utilized to extract silica sand from the earth’s crust.

获取价格

Silica Sand Washing Grading. Industrial Abrasives, Water Filtration, Glassmaking, Ceramics Industry all need high-precision silica sand. We design washing - drying - screening productin line help customers obtain high-quality silica sand. Square swing screen with a multi-layer screen design, which can obtain up to 5 sizes of silica sand

获取价格

2023/7/6 There are several techniques used to wash silica sand, including: (Before we have introduced the 6 methods for removing iron from silica sand). Scrubbing: This technique is used to remove clay and other impurities from the surface of the sand particles.. Washing: This technique involves washing the sand with water to remove

获取价格

1 Next, we have to wash the sand. Sand grains are cleaned to remove unwanted clay particles and silt. Clean sand is then pumped to settling tanks where flocculants are added to remove the remaining particles. Unusable sand containing particles infiltrating the material is reused as industrial sand, along with clay particles and silt.

获取价格

Products. AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant.

获取价格

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

获取价格

2023/11/7 Sand washing is a common process used in the construction industry to remove impurities and dust particles from sand, ensuring a cleaner and more efficient production of concrete and other building materials. 2. On a microscopic level, sand grains are not perfectly smooth, but rather have small protuberances and edges. When these

获取价格

2015/3/31 This report examines the various requirements for setting up a Silica Sand Manufacturing Plant. This includes manufacturing process, raw material requirements, land, labour, machinery, costs ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين