2024/6/21 The cement storage and transportation system refers to the transfer, loading, unloading and storage facilities required to transport cement from the cement

获取价格

Screw Conveyor. Our TD type and DTII type heavy belt conveyors used in cement plants both have great performance in the long-distance

获取价格

Elecon product range for the cement industry includes: Stackers. Twin -boom rail mounted stacker. Bridge type Scraper reclaimer. Pylon type Scraper reclaimer. Semi portal and Full portal Scraper reclaimer. Circular

获取价格

4 AUMUND Group Equipment in the Cement Industry 6 Clinker Transport 10 Conveying of Raw Meal, Cement and Additives 12 Transport of Raw Material, Clinker, Additives

获取价格

Cement and clinker bucket elevators are specialized equipment used to vertically transport bulk materials in the cement manufacturing process. They consist of a series of buckets attached to a belt or chain, which

获取价格

The cement industry is an excellent proving ground for air cannon technology, as it presents such a demanding operating environment, including extreme temperatures and abrasive materials that affect

获取价格

2018/1/1 The AUMUND name is synonymous with the supply of high quality equipment to transport materials used in the manufacture of Portland Cement, so it’s little surprise to know that SAMSON Materials

获取价格

transportation process in the cement industry activities. To minimize the risk and improvement in material handling process by using risk assessment methods, proper

获取价格

高达$3返现 61795934-Material-Handling-System-in-Cement-Industry.docx - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document discusses material handling

获取价格

2024/6/21 The cement storage and transportation system refers to the transfer, loading, unloading and storage facilities required to transport cement from the cement factory to the construction site. In the construction of large and medium-sized projects, due to the large demand for cement, bulk cement is usually used, and cylindrical silos (i.e.

获取价格

2024/1/9 The cement production process emits approximately 0.9 tons of CO 2 per ton of cement (Hasanbeigi et al. 2010), accounting for about 5–8% of global CO 2 emissions and ranking as the second-largest CO 2 emissions source (Mikulčić et al. 2016; Kajaste and Hurme 2016).According to the Intergovernmental Panel on Climate Change (IPCC)

获取价格

2011/5/1 Being an energy intensive industry, typically this segment of industry accounts for 50–60% of the total production costs [17].Thermal energy accounts for about 20–25% of the cement production cost [18].The typical electrical energy consumption of a modern cement plant is about 110–120 kWh per tonne of cement [19].The main thermal

获取价格

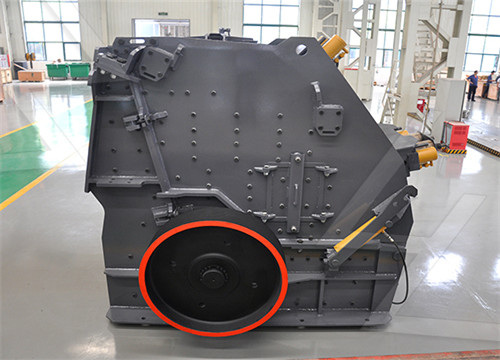

Water content below 10-12% seldom causes problems of stickiness in the types of crushers used within the cement industry. Hard materials causing severe abrasive wear are reduced with slow running machines such as jaw crushers and gyratory crushers, which function by developing mainly a compressive action.

获取价格

Cement and clinker bucket elevators are specialized equipment used to vertically transport bulk materials in the cement manufacturing process. They consist of a series of buckets attached to a belt or chain, which moves the materials from one level to another.

获取价格

The text is backed by over 100 years of research by the Portland Cement Association and other industry groups. It reflects the latest guidance on standards, specifications, and test methods of ASTM International (ASTM), the American Association of State Highway and Transportation Officials (AASHTO), and the American Concrete Institute (ACI ...

获取价格

2019/9/27 Cement equipment refers to the cement making machines that are applied to the cement manufacturing plant. Before learning the cement equipment, we learn the process of cement manufacturing process first. Cement manufacturing process. In general, we can divide the cement production line into three main steps: raw material

获取价格

2021/10/15 2.1. Carbon Footprint of Limestone Quarrying. Limestone is one of the largest produced crushed rocks which is the basic component of construction materials, such as aggregate, lime, cement, and building stones for the construction industry [].The energy required for lime quarrying is associated with the machine fuel, diesel, and

获取价格

2024/4/1 The requirements of clean transportation in cement industry are put forward in “Building materials industry carbon peak implementation plan”, “Make deep efforts to eliminate heavy pollution weather, ozone pollution prevention and control and diesel truck pollution control action plan” and “Opinions on promoting the implementation

获取价格

2014/8/18 Apart from limestone, other raw materials used in the cement industry are fly ash, slag, and gypsum. Transportation cost. In the cement sector, the manufacturing facilities and end-user markets ...

获取价格

2023/12/23 In the cement industry, centrifugal fans play a crucial role in various processes by providing the necessary air flow for combustion, material transport, and cooling. Different types of centrifugal fans are employed based on their specific applications. Here are some common types of process fans used in the cement industry:

获取价格

The cement industry is in the middle of adjusting to supply chain disruptions and conflicts around the world that came with the Covid pandemic. ... Cement is the primary material used in the construction of buildings, houses, highways, bridges and other constructed infrastructure. ... Truck is the most commonly used mode for finished cement ...

获取价格

storage piles. The material handling equipment used to transport clinker from the clinker coolers to storage and then to the finish mill is similar to that used to transport raw materials (e.g. belt conveyors, deep bucket conveyors, and bucket elevators). To produce powdered cement, the nodules of clinker are ground to the consistency of powder.

获取价格

2021/10/22 Challenges to achieving zero emissions in the cement industry stem in large part from the raw materials, such as limestone and crushed rock, that are widely available, and the well-established manufacturing technology used for cement production, which has been difficult to innovate. 11 While cement is just one constituent in products

获取价格

2023/12/23 In the cement industry, centrifugal fans play a crucial role in various processes by providing the necessary air flow for combustion, material transport, and cooling. Different types of centrifugal fans are

获取价格

The cement industry is in the middle of adjusting to supply chain disruptions and conflicts around the world that came with the Covid pandemic. ... Cement is the primary material used in the construction of

获取价格

storage piles. The material handling equipment used to transport clinker from the clinker coolers to storage and then to the finish mill is similar to that used to transport raw materials (e.g. belt conveyors, deep bucket conveyors, and bucket elevators). To produce powdered cement, the nodules of clinker are ground to the consistency of powder.

获取价格

2021/10/22 Challenges to achieving zero emissions in the cement industry stem in large part from the raw materials, such as limestone and crushed rock, that are widely available, and the well-established manufacturing technology used for cement production, which has been difficult to innovate. 11 While cement is just one constituent in products

获取价格

The level of the material in the feed bin is held constant by adjusting the material transport to and from the pelletizer to the grate. With increasing traveling grate speed the material feed rate increases and vice versa. 1.1.3 Pelletizer control

获取价格

Cement - Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be

获取价格

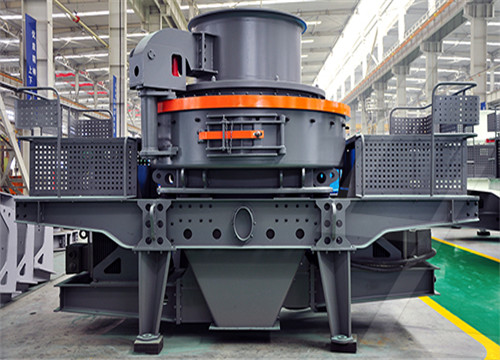

Previous Post Next Post Contents1 Coarse size reduction of raw materials in Cement Industry1.1 Size reduction machinery and methods1.1.1 A Machinery for size reduction in the coarse range (crushers) by application of compression:1.1.2 B Crushers for size reduction by impact:1.1.3 C For comminution in the fines range (grinding mills) by

获取价格

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions. This blended raw material is called the ‘raw feed’ or ‘kiln feed’ and is heated in a rotary kiln where it reaches a temperature of about 1400 C to 1500 C.

获取价格

2024/6/1 The heart of cement production is the kiln, where the raw materials are heated at high temperatures. The kiln operates at temperatures reaching around 1450 °C and allows for the chemical transformation of the raw materials into clinker [[37], [38], [39]].During this process, a series of complex reactions occur, including the

获取价格

2023/10/6 Decarbonizing the cement industry has never been more important.Globally, cement accounts for about 7 percent of total greenhouse-gas (GHG) emissions, one of the largest sectoral carbon footprints on the planet. 1 Sebastian Reiter, “Cement,” McKinsey Quarterly, August 1, 2022. Our research suggests that global

获取价格

Dust emissions are one of the most significant impacts of cement manufacturing and associated with handling and storage of raw materials (including crushing and grinding of raw materials), solid fuels, transportation of materials (e.g. by trucks or conveyor belts), kiln systems, clinker coolers, and mills, including clinker and limestone burning and

获取价格

In cement plant, vibrating feeder is usually used for raw material feeding before jaw crusher or other types of crushers, and disc feeder is often used for conveying small materials after the crusher crushing process. Conveyor. The conveyor is a kind of industrial equipment that can continuously and stably transport materials on a specific line.

获取价格

2019/2/14 From energy consumption point of view, cement industry is one of the most energy-intensive industries in the world. With a consumption level of 120 kWh/t of cement, the cement subsector accounts for approximately 10–15% of the total industrial energy used worldwide.

获取价格

Conditioning towers in the cement industry are used for cooling exhaust gases from the kiln before they are conveyed to the bag house. Inlet temperature from pre-heater to Gas Conditioning tower is 600 degree Celsius and outlet is 250 degree Celsius. This temperature is used to drying material in vertical raw mill.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين