Notes on the manganese ores of Brazil. January 1, 1951. Brazil has been a small but consistent source of manganese ore for world markets during the last five decades. Production both for export and for domestic use is likely to increase. Deposits can be

获取价格

2022/9/1 The present paper provides an overview of the artisanal and industrial phases of gold mining in Brazil, starting from the 18th century. Its objective is to present

获取价格

3 kg of Fe-Si-Mn (60$ Mn) =Total1.38 kg Mn= 13«38 k. At a recovery rate of 70$, total needed is 19*10 kg Mn. If the steel production of Brazil in the year 2000. is 66.3 million

获取价格

2021/12/1 Gold production in Minas Gerais during the 18th century, ... Usina Wigg's manganese ore production vis-à-vis, Brazil's production from 1895 to 1930 the 18th

获取价格

Brazil has been a small but consistent source of manganese ore for world markets during the last five decades. Production both for export and for domestic use is likely to

获取价格

The plant for the efficient processing of extracted manganese ore from highly oxidised, iron and silicate-rich sedimentary rock will increase the annual output at the mine from

获取价格

2023/3/8 The process system boundary and process diagram for manganese recovery are depicted in Fig. 1. As demonstrated in the figure, before the leaching

获取价格

Download scientific diagram Scheme of Manganese ore processing at Azul mine, Carajás, Pará, Brazil [3]. from publication: A Review of the Production of Ferromanganese in

获取价格

2017/9/12 The use of innovative allmineral technology is making a substantial contribution towards increasing production output at Brazil’s Espaigão mine. Starting in

获取价格

2024/5/7 Introduction to Manganese Ore: Manganese ore is a key raw material in the production of ferrous alloys, primarily steel. It’s also utilized in non-ferrous applications such as batteries ...

获取价格

CIL (Carbon In Leach), the gold carbon leaching method, is the carbon leaching method for gold extraction.Normally, the CIL process can concentrate gold from 2.5–3.5 g/t in ore to 2000 to 6000 g/t in carbon.

获取价格

2023/12/19 Since its first ore shipment in 2006 25, the project has progressively mined these deposits for manganese ore to feed its 1 Mt-per-annum plant for the production of manganese concentrate. The company anticipates that mining activity for 2019–2020 will continue at mines planned in selected areas of the Chugga Far North,

获取价格

PRODUCTION AND STOCKS The production of manganese ore at 2,904 thou-sand tonnes during 2019-20 increased by about 3% as compared to that in the previous year. There were 131 reporting mines during the year 2019-20 as against 148 in the previous year . Besides, manganese ore production was reported as associ-ate mineral by 12 mines

获取价格

Crushing screening: In the crushing and screening stage of lithium ore, a three-stage and one closed-circuit crushing and screening process, or a two-stage and one closed-circuit crushing and screening process can be adopted.Specifically, it is necessary to refer to the particle size of the raw ore and equip a reasonable lithium ore crushing process.

获取价格

2021/3/18 A reasonable grinding process is determined by the three most important factors: the hardness of the gold ore, the gold ore inlay, and the requirements for the particle size of the grinding product. The grinding process of the CIP gold processing plant is the same as that of the non-ferrous metal ore. There are also one and two stages of

获取价格

The current production is on average 5,000 t/m. The Plant produces tonnages which average at 35% lumpy and 35% fines product with 30% being produced as discard material. Fig. 9: Aerial view of the mining complex. Processing Plant. Ore is processed on site at a plant designed for low production volume of under 15,000 tons per month.

获取价格

The typical gold processing plant begins with a cone crusher, to reduce the particle size of the ore. Next, it is loaded on a conveyor belt, where an overbelt magnet removes tramp metal from the gold mining process. The ore goes for preliminary screening, followed by stream sampling, which is a process that uses a hammer sampler. A semi ...

获取价格

Types of Ore beneficiation plant, iron ore,gold ore,copper ore beneficiation machine. ... and own a professional and experienced engineer team and two large-scale modernized production bases. We supply suitable and practical equipments from crushing, grinding to beneficiation machines and other corollary equipments like vibrating feeder, belt ...

获取价格

2020/1/6 Comilog has been recovering manganese ore from the Moanda mine for nearly 60 years (Credit: Désirey Minkoh/Afrikimages) Brazil. With an annual production of about 1 million tones, Brazil is the fifth-largest manganese producer in the world. Vale is the largest manganese producer in Brazil, accounting for nearly 70% of the country’s market ...

获取价格

Value of manganese ore exported from Ghana 2010-2021; ... Basic Statistic Gold mine production volume in Ghana 2011-2021; Premium Statistic ...

获取价格

2018/6/1 Brazil is the second-largest producer of iron ore and pellets in the World. In 2014, 411.8 Mt of iron ore and 54.7 Mt of pellets were produced. ... Brazilian Iron Ore and Production of Pellets. ... Beneficiation and concentration steps are required to prepare these materials for the pelletizing process. A general view of Brazilian types of iron ...

获取价格

Manganese ore process flow: The manganese ore raw materials are crushed at production site. The massive manganese ore will go through the loading device to the hopper, and then feed evenly into the jaw crusher for primary crushing by vibrating feeder. The crushed materials send to the cone crusher for medium and fine crushing through []

获取价格

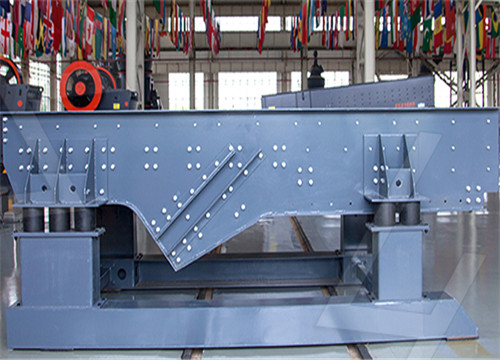

2022/1/13 This setup is for the manganese ore process:raw bin+vibration feeder, jaw crusher, belt conveyor, cone crusher, belt conveyor, vibration screen, belt conveyo...

获取价格

Value of manganese ore exported from Ghana 2010-2021; ... Basic Statistic Gold mine production volume in Ghana 2011-2021; Premium Statistic ...

获取价格

2018/6/1 Brazil is the second-largest producer of iron ore and pellets in the World. In 2014, 411.8 Mt of iron ore and 54.7 Mt of pellets were produced. ... Brazilian Iron Ore and Production of Pellets. ... Beneficiation and concentration steps are required to prepare these materials for the pelletizing process. A general view of Brazilian types of iron ...

获取价格

Manganese ore process flow: The manganese ore raw materials are crushed at production site. The massive manganese ore will go through the loading device to the hopper, and then feed evenly into the jaw

获取价格

2022/1/13 This setup is for the manganese ore process:raw bin+vibration feeder, jaw crusher, belt conveyor, cone crusher, belt conveyor, vibration screen, belt conveyo...

获取价格

The main source of Mn in raw materials for SiMn production is Mn-ore and Mn-rich slag from the high carbon FeMn production. The amount of slag per tonne of SiMn metal is mainly determined by the ore/slag ratio. Increasing share of FeMn slag at expense of Mn-ore will lead to larger slag/metal ratio in the SiMn process.

获取价格

Production of Ferro- Manganese. satyendra; June 19, 2018; ... which are very similar to the iron pyro-metallurgical processes. In its production process, a mixture of Mn ore, reductant (a form of C) and flux (CaO) are smelted at a temperature which is higher than 1200 deg C to enable reduction reactions and alloy formation. ... a cone of fast ...

获取价格

2016/2/29 Process Development Considering the different gold minerals present alone or combined with the host rock, it will be necessary to discharge the unwanted material in order to increase the concentration of gold in an economically manner. This part treats the strategy of beneficiation as a combination of several processes. Joining

获取价格

2021/8/6 1 Main equipment of manganese ore process plant. The main manganese mining equipment is 2 sets of PE400 mm×600 mm jaw crusher, 2 sets of CXK1 600 mm×7 630 mm tank washing machine, 2 sets of ZD150 mining single-shaft vibrating screen, FG -12 high-grade spiral classifier. 2 Existing problems in the manganese

获取价格

【Process Introduction】 Manganese ore belongs to the weak magnetic minerals, which can be recovered by high-intensity magnetic separator. Xinhai applies the magnetic process to separate manganese ore, including two stages, rough separate the high-intensity magnetic ore and concentrate the medium intensity magnetic ore, thus improve the

获取价格

Tin(Cassiterite) ore processing refers to the process of extracting tin from ore. Gravity separation, magnetic separation and flotation are mainly used to grade tin concentrate and remove other impurities.. In order to achieve high efficient, low-cost beneficiation flow, JXSC will custom process and equipment according to ore characteristics.

获取价格

2024/4/26 Cone crushers are capable of producing finer-sized ore particles compared to jaw crushers. The crushed ore obtained from the crushing stage is typically in larger size fractions and needs to be further processed through screening. 2. Screening. Screening is the process of separating the crushed ore into various size fractions.

获取价格

2024/4/9 The process flow diagram for the electrolytic production of manganese includes seven process stages: Leaching Ore or Concentrate with Sulfuric Acid After crushing to a fraction of 0-20 mm and averaging carbonate manganese ore, a belt conveyor feeds it into an intermediate bin with a batch-weighing feeder for grinding in a ball mill.

获取价格

2024/8/14 Rotary scrubber. The rotary scrubber is used to clean and screen ore with large mud content but is challenging to wash. The long washing cylinder allows the material to stay inside for a long time, with a vigorous scrubbing ability. The high-pressure washing water washes the inner wall, thoroughly and powerfully dispersing the material completely.

获取价格

2021/11/5 High gold price has increased the focus on the development of refractory gold ores and concentrates. The launch of the compact Elution and Goldroom plant has completed Metso Outotec’s run-of-mine ore to doré process flowsheet and at the same time enabled us to provide a leading standardised solution for the forming of concentrated

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين