2024/5/28 The iron ore raw materials are evenly fed by the TSW feeder, enter the high-energy jaw crusher for coarse crushing, and then enter the cone crusher CS for secondary crushing. The intermediate crushed stone enters the vibrating screen for

获取价格

2023/3/31 Generally, jaw crusher is used as coarse crushing equipment in small-scaled iron ore processing plants or quarries. 3. The gyratory crusher adopt continuous crushing, with its outstanding

获取价格

2024/4/26 These processes involve breaking down the mined ore into smaller fragments and separating it based on size. Let's explore the crushing and screening stages in more detail: 1. Crushing. Crushing is

获取价格

China’s concentrators generally adopt the three-stage crushing process of coarse crushing, medium crushing, and fine crushing to crush iron ore. 1.2m or 1.5m jaw crushers are mostly used for coarse breaking, cone

获取价格

A typical iron ore fines crusher flow sheet is shown in Figure 1, using a high-capacity sizer as a primary crusher followed by screening and cone crushers. HiStorY Batch crushing

获取价格

3 Screening machines for iron ore and coal. The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. ... after the scrubber and

获取价格

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ... as the production continues through an on

获取价格

2023/7/1 Download Citation Innovative solutions to improve the efficiency of coarse crushing in iron ore mining and processing plants The need to increase the capacity

获取价格

Iron exist in nature all in compounds state, especially in the state of iron oxide but has more impurities. Such as hematite, magnetite, siderite, limonite, etc. IRON ORE CRUSHING PROCESSING. 1.Crushing and

获取价格

Iron Ore Crusher Working Process. Iron ore dressing, according to the type and nature of ore, can have a variety of different processes. Concentrator generally used coarse crushing, middle crushing and fine crushing three stage. In the iron ore crushing production line, in order to improve the production efficiency of iron ore crusher, reduce ...

获取价格

When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the

获取价格

Crushing, a form of comminution, one of the unit operations of mineral processing. Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.. Beneficiation is any

获取价格

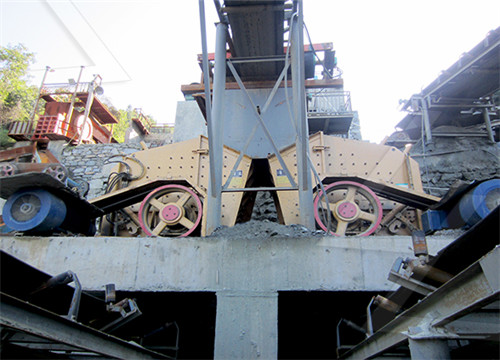

In iron ore crushing process include coarse crushing, medium crushing, fine crushing and pulverizing. In iron ore crushing plant , jaw crusher is often to be selected, in medium crushing process, processer usually use impact crusher, and in the fine crushing, short-head type cone crusher is suitable.

获取价格

The rock/ore crushing processing plant requires applying different crushers, including jaw crushers, impact crushers, cone crushers, roll crushers, sand making machines, etc. ... Mine rock ore crushing: iron ore, copper ore, gold, lead-zinc, coal, manganese ore, silica ... Application: Primary crushing, which is the first step coarse crushing ...

获取价格

2022/1/1 Some examples of different iron ore crushing and screening flowsheets are provided below: 8.2.3.1. Rio Tinto iron ore processing plants. Rio Tinto Iron ore processing plants in the Pilbara region of Western Australia do not involve any chemical treatment. Flow sheets for the ... fed from the coarse ore stockpile, remove as much

获取价格

This means that the number of crushing stages can be reduced depending on the feed size accepted by primary grinding stage. Image of a “Classical” 3-stage ore crushing prior to rod mill [image: (135-5-1)] Diagram of Typical 1-2 stage ore crushing prior to AG-SAG mill [image: (135-5-2)] Calculation of Reduction Ratio in Crushing

获取价格

2022/10/20 Therefore, if a 24-h supply of ore that has passed the coarse crushing plant is kept in reserve ahead of the mill, the mill can be kept running without stop if the shutdowns were less than 24 h at mine and coarse crushing plants. ... Iron ore sintering plants are associated with the manufacture of iron and steel, often in integrated steel

获取价格

3 Screening machines for iron ore and coal. The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. ... after the scrubber and after the tertiary comminution stage to separate the iron ore into a dry coarse fraction (8 – 40 mm) and a wet fine fraction (> 1 ...

获取价格

A typical iron ore fines crusher flow sheet is shown in Figure 1, using a high-capacity sizer as a primary crusher followed by screening and cone crushers. HiStorY Batch crushing plants The history of mobile crushing plants started with roadside crushing and screening operations and more particularly gravel quarries located near the road works.

获取价格

Then iron ore is fed into primary crusher offers Mbalam iron ore a technological process in the iron ore crushing plant line. Iron Ore – AIMR 2011

获取价格

To sum up, crusher and Iron ore crusher in malaysia all belong to crushing equipment. Crusher and ball mill is an integral part of beneficiation equipments, crusher is mainly used to do the work at earlier stage, the ball mill is used to do the coarse grinding and fine grinding at later stage. Our potash processing plant is popular on the market of mining,

获取价格

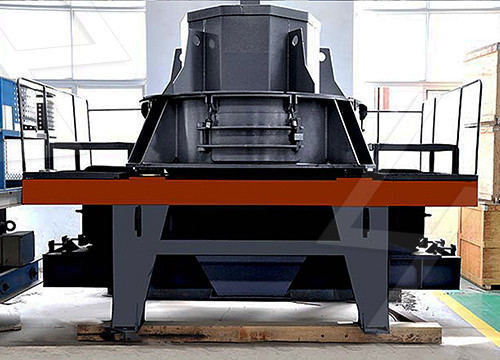

IRON ORE CRUSHING PLANTS DESIGN. 1. Feeding: Iron ore is evenly fed to the jaw crusher by a vibrating feeder for coarse crushing. 2. Primary Crushing: Coarse crushing of iron ore by the jaw crusher. 3. Secondary Crushing: Coarse crushed materials are conveyed to the cone crusher by a belt conveyor for further crushing. 4.

获取价格

K3 series Portable Crushing Plant uses modular vehicle design, able to be transported without disassembly. ... basalt, limestone, quartzite, pebble, iron ore, copper ore, mine waste, construction waste, etc. Advantages. 1. Modular Vehicle Design The coarse crushing module adopts the vibrating feeder of larger specifications, equipped with ...

获取价格

Then iron ore is fed into primary crusher offers Mbalam iron ore a technological process in the iron ore crushing plant line. Iron Ore – AIMR 2011

获取价格

To sum up, crusher and Iron ore crusher in malaysia all belong to crushing equipment. Crusher and ball mill is an integral part of beneficiation equipments, crusher is mainly used to do the work at earlier stage, the ball mill is used to do the coarse grinding and fine grinding at later stage. Our potash processing plant is popular on the market of mining,

获取价格

IRON ORE CRUSHING PLANTS DESIGN. 1. Feeding: Iron ore is evenly fed to the jaw crusher by a vibrating feeder for coarse crushing. 2. Primary Crushing: Coarse crushing of iron ore by the jaw crusher. 3. Secondary Crushing: Coarse crushed materials are conveyed to the cone crusher by a belt conveyor for further crushing. 4.

获取价格

K3 series Portable Crushing Plant uses modular vehicle design, able to be transported without disassembly. ... basalt, limestone, quartzite, pebble, iron ore, copper ore, mine waste, construction waste, etc. Advantages. 1. Modular Vehicle Design The coarse crushing module adopts the vibrating feeder of larger specifications, equipped with ...

获取价格

Technological Process of iron ore crushing plant is: Iron ore----- transported by the dump truck ----- Vibrating feeder ----- Jaw crusher (Primary crusher) ----- Spring cone crusher (Secondary crusher) ----- Circular vibrating screen ----- finished product as the customer required ... so it is the ideal choice of the iron ore coarse crushing. 2 ...

获取价格

A DELKOR APIC jig was supplied as part of a contract to provide plant engineering for the complete crushing, screening and jigging plant for iron ore beneficiation. The jig, was at the time of the contract, the largest in the iron ore beneficiation industry in India, and is an important reference for 4 m wide APIC jigs.

获取价格

Processing materials: iron ore, ironstone, hematite, brown iron. This stone crushing plant also uses a jaw crusher, cone crusher, vibrating screen, belt conveyor, and other related machines. The stone crushing plant is customized to the hardness of iron ore.

获取价格

2016/3/10 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2-in. size, but they work much more efficiently if their feed is ½ in. or less.

获取价格

CE Africa series Jaw Crushers are mainly applied to coarse crushing in mine and aggregate industries, with the processing capacity ranging from 60 to 1,500t/h as coarse crushing when cooperating with CE Africa’s series grizzly feeders, so it can meet the requirements of small and middle-large size coarse crushing in most cases.

获取价格

2023/2/15 Coarse-grained hematite refers to iron ore with an embedded particle size of 2mm or more. It is easy to extract iron from this kind of haematite by using gravity separation and magnetic separation. Medium-grained hematite refers to iron ore with an embedded particle size between 0.02 and 2mm. This type of hematite is also relatively

获取价格

Reducing Grinding Energy and Cost - Magnetite Iron Ore Design Case Study A. Jankovic and W. Valery Metso Process Technology Innovation, PO Box 1028, Eagle Farm Qld, 4009, Australia

获取价格

2023/7/1 Download Citation Innovative solutions to improve the efficiency of coarse crushing in iron ore mining and processing plants The need to increase the capacity of crushing and processing ...

获取价格

Iron Ore Process Plant. The world’s iron ore resources are concentration australia wide, Brazil, Ukraine, Russia, Kazakhstan, India, the usa, Nigeria, Canada as well as other countries. ... cone crusher come with an excellent fine crushing power to minish iron ore size. In coarse crushing, 2.1m or 2.2m gyratory crusher is usually being ...

获取价格

2019/8/23 150TPH Iron Ore Processing Plant in Malaysia 150TPH Hematite Ore Crushing Plant in South Africa. ... The permanent magnet large-diameter magnetic separator can effectively separate 0-3mm coarse-grained iron ore with a trailing yield of 30-50% and a tailings grade of 8% or less. Stage grinding, stage selection, coarse-fine

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين