Stone crushers are designed to achieve high crushing efficiency, allowing for the rapid processing of materials and increased productivity in various industrial applications.

获取价格

2023/2/28 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications. These plants find application in

获取价格

2024/8/14 Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable operation, low failure rate, and not easy to be crushed. Disadvantages: The structure

获取价格

2023/7/28 1. Jaw Crushers. Source: . Initiating our exploration, the first stone crusher we encounter is the jaw crusher. This type of machine boasts a simplistic yet highly effective design, employing

获取价格

Learn different techniques and equipment used for crushing stone and their various applications. Identifying Rock Types and Their Hardness. There are two critical factors

获取价格

Contact us today to discuss your rock crushing application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry

获取价格

2023/2/22 In this article, we will discuss the different types of stone crusher machines and their applications. Jaw Crusher. Primary Jaw Crusher: This type of jaw crusher is used for the first stage of crushing

获取价格

2024/4/3 The correct installation of stone crusher is imperative for safe and efficient long-term operation. As key equipment in crushing applications, stone crusher

获取价格

2019/11/11 Crushed stone: The term “crushed stone” usually refers to stone that has a mixture of stone dust in it. This type of stone is best used for a base when heavy compaction is needed. As a result, it is

获取价格

2023/2/24 Stone crushing is an essential activity that involves the crushing of large stones into small pieces or gravel to be used in construction or other applications. Stone crusher plants are among the

获取价格

2020/1/3 Robust demand for stone crushers in quarries. Proliferating demand for crushed rocks and aggregates needed for across a host of application verticals has sustained its manufacturing and

获取价格

3. Suitability for Specific Applications. The suitability of stone crusher machines for specific applications is crucial for achieving optimal results. Different projects may require crushers capable of handling specific stone types, processing varying hardness levels, or meeting specific output requirements.

获取价格

Types: Small portable jaw crusher with vibrating screen; Small portable jaw crusher with belt conveyor; Small portable hammer crusher; Application: The small portable rock crushers widely used to crush and screen various rocks, stone, aggregates, construction materials and ores, including limestone, granite, marble, gypsum, basalt, iron ore, copper

获取价格

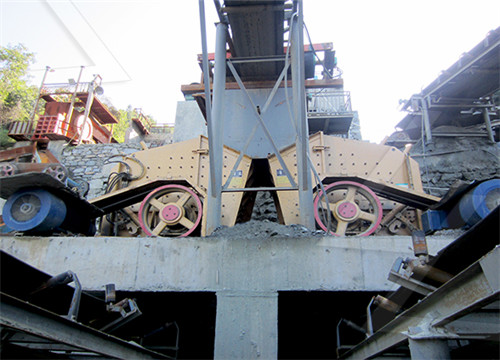

2024/7/15 Then the crushed material will hit aprons again in the crushing chamber, which is "stone on stone" crushing way. The outstanding feature of impact rock crusher is that it can fully utilize natural cleavage of material to produce a wonderful cubic product which is desirable for many of today's specifications.

获取价格

Hammer Mills Williams manufactures a large variety of hammer mills and hammer crushers well-suited to handle limestone crushing applications. As the manufacturer holding the very first hammer mill patent to utilize mid-air impact crushing, Williams takes great pride in providing quality, rugged machines for many applications.

获取价格

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece.

获取价格

2024/3/19 Construction: They are heavily involved in the production of high-quality aggregates used in the construction of concrete, roadways, and other infrastructure projects.They are employed in the crushing of hard rocks, such as quartzite, granite, and basalt, into various sized gravel, crushed stone, and sand particles.

获取价格

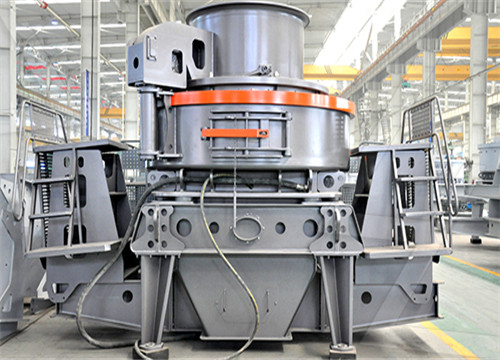

2024/3/1 A stone crushing plant needs essential primary crushers like jaw and gyratory crushers as well as fine-crushing equipment like impact crushers and ball mills. Other critical heavy-duty machines for the effective operation of a stone mill include the belt conveyors, vibration feeder, vibrating screens, and a central control system for all these ...

获取价格

2020/7/27 Each grade has a unique application. When you need crushed stone, it’s handy to know what the different grades mean. The information below provides a general overview to help you choose the right material for your project. Crushed Stone Grade 1-10. Generally, as the grade number goes up, the size of the stone goes down. #1 – The # 1

获取价格

2021/4/16 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per ...

获取价格

Industry: Quarry Application: Stone Crusher Problem: Extreme weather conditions are common in quarries; pair that with repetitive contact with abrasive materials and the result is frequent failings of traditional rubber v-belts in stone crushers. Solution: Fenner Drives HPC product line offers a solution with the NuTLink V-belt because of its unique blend of

获取价格

2023/2/24 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; ... They are commonly used in quarrying, mining, and recycling applications. Mobile Cone Crushers: Mobile cone crushers are designed to crush hard and abrasive stones or materials. They are ideal for

获取价格

2020/7/27 Each grade has a unique application. When you need crushed stone, it’s handy to know what the different grades mean. The information below provides a general overview to help you choose the

获取价格

2021/4/16 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The

获取价格

Industry: Quarry Application: Stone Crusher Problem: Extreme weather conditions are common in quarries; pair that with repetitive contact with abrasive materials and the result is frequent failings of traditional rubber

获取价格

2023/2/24 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; ... They are commonly used in quarrying, mining, and recycling applications. Mobile Cone Crushers: Mobile cone crushers are designed to crush hard and abrasive stones or materials. They are ideal for

获取价格

The PTH Crusher is the ultimate stone crusher for continuous use in hard stone and demanding soils with outstanding performance. Zum Inhalt wechseln. ... Stone crusher for particularly tough applications. 0:54. PTH Crusher in road construction - Erzberg Austria 4:58. PTH Crusher 2500HD PTH Ripper on grant stone

获取价格

For stone crushing applications, Schutte Hammermill offers a range of robust and versatile equipment tailored to meet the unique demands of the industry. Our mills play a crucial role in the size reduction process for various types of stones, ensuring consistent and precisely controlled particle sizes. The ruggedly constructed SC Series Stone ...

获取价格

In 1883 Mr. Blake challenged Mr. Gates to crush 9 cubic yards of stone in a contest to see which crusher would finish the job faster. The Gates crusher completed the task 40 minutes sooner! ... Jaw Crushers: Ideal for heavy-duty primary crushing applications. Cone Crushers: Perfect for secondary and tertiary crushing with precise output.

获取价格

Learn different techniques and equipment used for crushing stone and their various applications. Identifying Rock Types and Their Hardness. There are two critical factors influencing choice of crushing techniques and equipment. Hardness of the rock and abrasiveness. Hardness of the rock is typically measured using the Mohs scale, where

获取价格

FAE stone crusher applications Applications for stone crushers for tractors. In places where rocks are an issue, FAE has the answer. Whether its forestry maintenance, plantation, vineyard or orchard maintenance, agriculture tilling or soil reclamation, FAE has the right product for the job. FAE stone crushers are also highly useful for ...

获取价格

SPECIALTY TYPES #57 - Contains particles about ¾ inch in diameter. #67 - Contains particles ¾ inch or less in diameter. #411 - #57 stone and #10 stone screenings mixed together.. There are also more specialty types, but these are some common ones. Classified by Washed vs. Unwashed Gravel . Some gravel is still mixed with stone dust or clay and

获取价格

Features of Williams Impact Crushers. Williams Patent Crusher manufactures a variety of industrial-grade impact crushers that deliver superior performance with increased efficiency. Our crushing machines offer a lot of value to your application because of the many features we have designed with our customers in mind.

获取价格

The jaw chamber configuration can be set up specifically for either processing construction demolition debris or quarrying applications. The J-1170 Stone Crusher features a heavy duty variable speed VGF and integrated prescreen giving excellent production throughput in quarrying, mining, demolition and recycling applications.

获取价格

2021/3/25 The right primary crusher for an application depends on several factors: Material to be crushed Feed size Desired product size Capacity required Compressive strength of the feed Moisture content The material and its characteristics, e.g., its hardness, density, shape and condition, will affect the type of crusher that needs to be used. ...

获取价格

2024/7/17 Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor transport and downstream processing. The three main types of primary crushers are jaw crushers, gyratory crushers, and hammer crushers. Jaw Crusher

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين