Clinker – 11. Finish mill – 12. Cement – 13. Quality control – 14. Packing and distribution – 15. Emission abatement (dust, NO x, SO 2, etc) – 16. Maintenance – 17. Process – 18. Materials analysis –19. Plant capacity summary – 20. Storage capacity 15. Cement

获取价格

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the eff

获取价格

Raw milling must produce sufficient feeq to sustain the required kiln production, meeting targets for fineness, chemica lcomposition and

获取价格

/ Plant / Factory Manager Job Description. Plant / Factory Manager Job Description. A plant manager, also known as a factory or operations manager, has the general

获取价格

together in a raw mill to a particle size of 90 micrometres, producing “kiln feed” Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is

获取价格

Part Three: Raw Mill. Process of Raw Mill The proportioned raw material is feed first to a grinding mill. In the mill, particles ground in to very fine sizes. In the grinding unit, drying, grinding and mixing takes place

获取价格

2012/4/30 2.1.3 Process Description. ... The objective of this article is the development of a novel raw material mix proportion control algorithm for a cement plant raw mill, so as to maintain preset ...

获取价格

2021/1/1 The raw mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier. The hot gases from the pre heater enter the mill and are used for

获取价格

Maintenance is often the largest controllable operating cost in the cement industry and hence a critical business function. Maintenance should be regarded in best practice organizations not simply as a cost to be

获取价格

2018/3/8 Manager Production, Raw Mill Ibeses Plant (Cement) Position : manager production, raw mill ibeses plant (cement) we're looking for manager production, raw

获取价格

Plant / Factory Manager Job Description 2018 - Job ... / Plant / Factory Manager Job Description. Plant / Factory Manager Job Description. A plant manager, also known as a factory or operations manager, has the general responsibility of maintaining a manufacturing plant's operations including storage and shipping of products. ...

获取价格

• At least 2 to 5 work experience as Production Supervisor in Cement industry Specific Knowledge • Good knowledge of cement process and quality • Knowledge of vertical roller mill operation and process • Knowledge of Mechanical and electrical equipment’s • Basic knowledge on preventive maintenance tools and parameters.

获取价格

In a cement plant, nearly 35% heat is lost, primarily from the preheater and cooler waste gases. This corresponds to around 70 to 75 MW of thermal energy. This energy can be tapped by installing a Waste Heat Recovery Power Plant (WHRPP). Size of WHRPP is influenced by the moisture content present in raw material and fuel (coal).

获取价格

2024/2/23 The operation of the cement raw mill is a critical step in cement production. By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process. Therefore, the efficient operation of the cement raw mill directly impacts the

获取价格

2022/3/3 Rolling mill cracks, tubing failure, pump failure, spoke breakage ... A machine with a lower health score is flagged to the plant supervisor or plant engineer with a diagnostic assessment of the probable cause for the anomaly and a recommendation on improving the same. ... Predictive Maintenance as a Service for your cement plant can

获取价格

2021/10/14 S Agarwal and NK Tiwary review manpower status and requirements of the cement industry, modes of training, methodology and the NCB’s initiatives in providing a skilled technical human resource base, besides upgrading existing manpower skills.. The cement industry in India has undergone a paradigm shift in recent years. It is the second

获取价格

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

获取价格

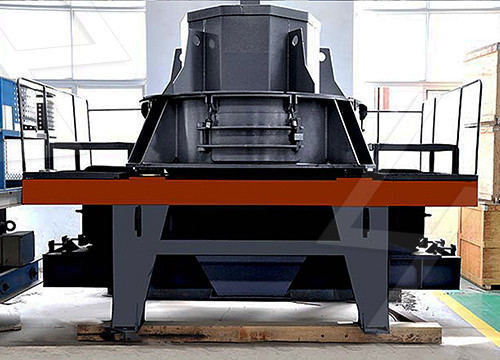

AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System. Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants.Compared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play

获取价格

This is very important, particularly in the situation when the moisture content of raw material is on higher side and the deficiency of hot gas in mill can effect on mill throughput or reduce mill outlet material temperature below 80 o C. Rotary feeders (gravel gate), double flap valve are used to stop/minimize cold air leakage into mill system ...

获取价格

2012/4/30 2.1.3 Process Description. ... The objective of this article is the development of a novel raw material mix proportion control algorithm for a cement plant raw mill, so as to maintain preset ...

获取价格

2018/3/8 Manager Production, Raw Mill Ibeses Plant (Cement) Position : manager production, raw mill ibeses plant (cement) we're looking for manager production, raw mill ibeses plant (cement). description. responsible for production planning, operation and entire management of the production process assigned to him. ensuring quality and iso

获取价格

During 2021, crews simultaneously erected a vertical raw mill, a preheater tower with an advanced kiln line and cooler, an automated clay storage system, an alternative fuel storage facility and finally, a fully automatic integrated laboratory and control center. ... Plant Manager, National Cement Company of Alabama, Inc., Guy Sidos, President ...

获取价格

In the diagram above of a precalciner kiln, raw meal passes down the preheater tower while hot gases rise up, heating the raw meal. At 'A,' the raw meal largely decarbonates; at 'B,' the temperature is 1000 C - 1200 C and intermediate compounds are forming and at 'C,' the burning zone, clinker nodules and the final clinker minerals form.

获取价格

The main difference to cement mill operation is the need to dry rawfeed and assure transport of stightly moist materialwithin a mill. ... (201312) describe a plant trialusing an extremely-coarse raw mix, following laboratory tests in which calcareous raw materialwas ground more coarsely. ... pragmatic trend to converge on a ‘standard ...

获取价格

2018/3/8 Raw Mill Process Cement Togo - Vetura Mining Machinery. Manager Production, Raw Mill Ibeses Plant (Cement) Position : manager production, raw mill ibeses plant (cement) we're looking for manager production, raw mill ibeses plant (cement). description. responsible for production planning, operation and entire

获取价格

During 2021, crews simultaneously erected a vertical raw mill, a preheater tower with an advanced kiln line and cooler, an automated clay storage system, an alternative fuel storage facility and finally, a fully automatic integrated laboratory and control center. ... Plant Manager, National Cement Company of Alabama, Inc., Guy Sidos, President ...

获取价格

In the diagram above of a precalciner kiln, raw meal passes down the preheater tower while hot gases rise up, heating the raw meal. At 'A,' the raw meal largely decarbonates; at 'B,' the temperature is 1000 C - 1200

获取价格

The main difference to cement mill operation is the need to dry rawfeed and assure transport of stightly moist materialwithin a mill. ... (201312) describe a plant trialusing an extremely-coarse raw mix, following laboratory tests in which calcareous raw materialwas ground more coarsely. ... pragmatic trend to converge on a ‘standard ...

获取价格

GRINDING BALL MILL MAINTENANCE COURSE; CEMENT HYDRAULIC MAINTENANCE COURSE; ... and efficiency of the plant assets, a manager ensures that a company does not need to invest in excess assets to produce its products. The objective of maintenance is not only to prevent the plant machinery and equipment from failure and breakdowns,

获取价格

Dust emissions are one of the most significant impacts of cement manufacturing and associated with handling and storage of raw materials (including crushing and grinding of raw materials), solid fuels, transportation of materials (e.g. by trucks or conveyor belts), kiln systems, clinker coolers, and mills, including clinker and limestone burning and

获取价格

2023/7/4 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding. It is an energy-efficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axis.

获取价格

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

获取价格

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills. Closed circuit ball mill with two compartments for ...

获取价格

Part Three: Raw Mill. Process of Raw Mill The proportioned raw material is feed first to a grinding mill. In the mill, particles ground in to very fine sizes. In the grinding unit, drying, grinding and mixing takes place simultaneously. Hot gas from clinker burning unit is passed into the grinding unit to assist the drying and grinding process.

获取价格

1.3 Technical Features of Cement Plant 07 1.4 Technical Features of Power Plant 08 ... Raw mill Cement Mill by M/s Polysius, Germany. Line-IV Cement plant was commissioned in the year 2009. Pyro processing equipment has been supplied by M/s FL Smidth, Denmark; Coal mill by M/s Gebr. ... S.NO. DESCRIPTION UNIT-I to IV

获取价格

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4.

获取价格

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

获取价格

Before you send inquiry. Please provide us with project information as much as possible: For a complete project: the material availability, the required output capacity, the process technology, your budgetary and financing status, the estimated starting time, etc.. For singular machinery: the model, the capacity, your budgetary information, other

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين