2024/6/11 Here are key maintenance activities that should be regularly performed on coal mills: 1. Regular Inspections. - Visual Inspection: Conduct routine visual inspections

获取价格

pulverizers is ¾” to 1”. Raw coal feed should never exceed 1¼”, raw coal this size can plug throats and cause vibration. Raw coal that is too fine can plug the pulverizer or delivery

获取价格

Proper Ventilation: Ensuring adequate ventilation in the coal mill area helps disperse coal dust and reduce the risk of ignition. Ventilation systems must be designed to handle the

获取价格

2011/8/1 In essence, the performance of a pulverizer is a delicate balancing act between the HGI, fuel fineness, and throughput. 1. A typical MPS-89 pulverizer found in many coal-fired power plants ...

获取价格

YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in

获取价格

By adhering to these best practices and implementing robust safety measures, the risks associated with coal mills can be significantly reduced. Regular maintenance, effective

获取价格

2023/8/11 The design of its coal mills focuses on ease of maintenance, with features such as easy access to internal components and efficient cleaning mechanisms.

获取价格

高达$3返现 The document provides standard maintenance procedures for performing preventative maintenance on a coal mill. It outlines the responsibilities of the maintenance engineer and steps to check components

获取价格

Nomenclature-Bowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill. If the number is odd then its deep bowl mill 3 - number of rollers three nos. X - frequency of power supply 50 cycles.In USA ’x’ means 60 cycles. R- Raymond, name of the inventor

获取价格

Construction And Maintenance Of Coal Mill Crusher BOWL MILL : Download free PDF books about BOWL MILL or

获取价格

Our mission at National Mill Maintenance is to exceed our customers' expectation on every job by providing value-added Mill Maintenance, Field Services, and Hydraulic Services to customers through knowledge,

获取价格

As a result maintenance downtime is reduced and work is easy and safe. Our MPS vertical mills. MPS 4750 BC cement mill, Holcim Val de Seine, France ... MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine. MPS 3070 BK coal mill, Jaypee Cement Balaji, India. MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum ...

获取价格

A ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill. A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production. In this article, we will discuss the importance of regular maintenance, pre-maintenance steps, the ball mill maintenance procedure,

获取价格

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performance.

获取价格

Bowl Mill has long been recognized as the most advantageous design of the coal pulverisers and include low initial cost, low maintenance cost, removal of tramp iron, low power consumption, easy maintenance, wide range output, quiet operation. The basic features of Bowl Mill (Puveriser) supplied by BHEL are:

获取价格

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM 12.2 D). 1980 Delivery of first modular coal mill (LM 26.3 D). 1985 Delivery of first self-inerting coal grinding plant (LM 21.2 D) for the

获取价格

2021/3/12 During start-up and maintenance the rollers can be lifted by tensioning cylinders. ... Commissioning of many coal mills is currently in progress. In the Ukraine an MPS 200 BK for coal grinding was commissioned in early 2013. All performance warranties were fulfilled. The warranties were based on a Hardgrove index of 40, the performance

获取价格

2020/12/21 C. Wang, "A Study of Condition-based Maintenance for HP983 Medium Speed Mills of Milling System In Coal-burning Power Station. Master thesis," Huazhong University of Science and Technology, Wuhan, 2007. ... Y. Li, L. Tian, Y. Gao, and Y. Li, "Monitoring Model of Coal Mill in Power Plant Based on Big Data and BP Neural

获取价格

and low maintenance. The mill heads are cast integral with trunnions which are supported in special heavy duty water-cooled bearings. Pressurized air seals between the rotating mill and inlet/outlet boxes prevent leakage of coal dust or air from the mill. Each mill is completely enclosed in an insulated sound-attenuating housing

获取价格

2015/11/1 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills. In this paper, a dynamic coal mill model is developed using conservation laws and empirical relations. The physical processes occurring inside the mill such as grinding, pneumatic transport ...

获取价格

The digital transformation of industrial processes offers new possibilities for improving plant performance and reliability. Machine learning and deep learning algorithms have been applied to monitor plant health and develop better maintenance and testing strategies. This paper focuses on the application of these techniques to a coal-fired power plant in South

获取价格

1998/3/30 This paper describes how an integrated approach to maintenance of the Babcock 10E Coal Mill has been developed at National Power's Blyth 'B' Station on the North East coast of England. The paper gives details of the types of mechanical problems experienced with the plant, and the various engineering, maintenance, and monitoring

获取价格

and low maintenance. The mill heads are cast integral with trunnions which are supported in special heavy duty water-cooled bearings. Pressurized air seals between the rotating mill and inlet/outlet boxes prevent leakage of coal dust or air from the mill. Each mill is completely enclosed in an insulated sound-attenuating housing

获取价格

2015/11/1 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills. In this paper, a dynamic coal mill model is developed using conservation laws and empirical relations. The physical processes occurring inside the mill such as grinding, pneumatic transport ...

获取价格

The digital transformation of industrial processes offers new possibilities for improving plant performance and reliability. Machine learning and deep learning algorithms have been applied to monitor plant health and develop better maintenance and testing strategies. This paper focuses on the application of these techniques to a coal-fired power plant in South

获取价格

1998/3/30 This paper describes how an integrated approach to maintenance of the Babcock 10E Coal Mill has been developed at National Power's Blyth 'B' Station on the North East coast of England. The paper gives details of the types of mechanical problems experienced with the plant, and the various engineering, maintenance, and monitoring

获取价格

Abstract: In order to monitor the wear condition of grinding roller of coal mill in power plant and improve the reliability of production equipment, it is necessary to establish a state monitoring model with high accuracy and good prediction effect. It has been shown that the power of coal mill can reflect the wear degree of grinding roller. If the voltage and power

获取价格

2021/5/12 Babcock is helping to keep South Africa’s power going, following the award of a mill maintenance contract at a major power station. Babcock’s diverse scope of work for the five-year contract covers the day-to-day upkeep of the milling plant as well as outage repairs, quality and inventory support, and on-site training and upskilling of the

获取价格

109 Commerce Drive Fort Collins, Colorado 80524 Ph: 970-221-4888 Ext 101 - Sales Ext 102 - Engineering Ext 103 - Accounting

获取价格

2021/5/14 The mill operates 24-hours a day and is responsible for the grinding, drying, transporting and classification of the coal. Babcock’s mill maintenance specialist says that the reliability of the mill is essential to ensure correct coal fineness, dryness and throughput, with the performance of the milling plant significantly impacting on plant ...

获取价格

By using the criticality and output measurement, paper devices a predictive maintenance policy for a coal pulverizing mill. Keywords: Predictive maintenance, FMECA, Coal pulverizing mill, t ...

获取价格

2020/5/27 Visual inspections and planned maintenance can extend the life of equipment in the prep plant by steve fiscor, editor-in-chief Compared to working sections in an underground mine, preparation plants are much more complex mechanically per square foot. The plant’s conveyor network consists of a series of short, fixed flights that move

获取价格

2013/1/6 This paper proposes a predictive maintenance policy for a coal pulverizing mill by integrating the Failure Mode Effect and Criticality Analysis (FMECA) and output measurement.

获取价格

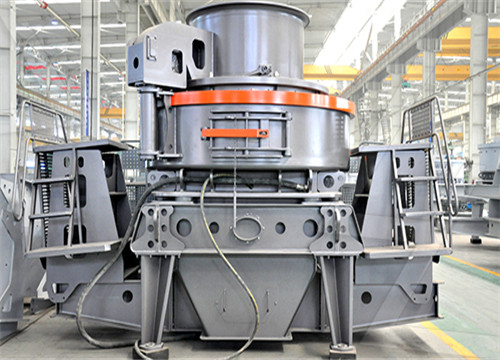

Introduction. This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can -and are- used for other purposes.. The 3D model in the saVRee database represents a vertical grinding bowl mill.Other grinding mill types include the ball tube mill, hammer mill, ball and race mill,

获取价格

Coal mill is the main equipment in the industrial pulverizing system. It is the key to ensure the stable and efficient operation of the pulverizing system to effectively use the production operation data to establish the process monitoring model and timely investigate the abnormal cause variables. In view of the problem that it is difficult to establish the

获取价格

2024/6/11 Maintaining a coal mill is critical for ensuring its efficient and safe operation. Here are key maintenance activities that should be regularly performed on coal mills: 1.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين