These Hammer Mills are designed and built to low abrasive material, such as ... Portugal T +351 255 420 580 F +351 255 420 589 [email protected] metalomarao.pt

获取价格

2021/11/29 In addition to the above selection skills, we should also pay attention to the use of hammerhead of hammer crusher and make a reasonable selection, so as to

获取价格

thyssenkrupp Polysius crusher power at Yamama sites. Since 1976, we have repeatedly been able to supply Yamama Cement Company with our mobile crushing plants. For the

获取价格

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a

获取价格

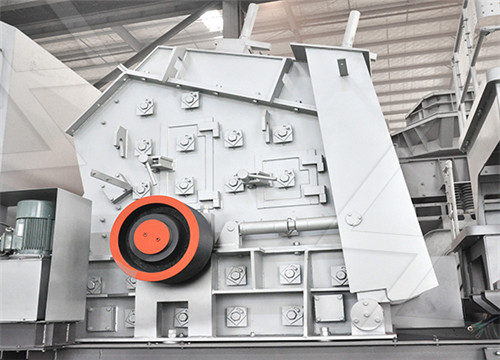

2016/2/25 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far

获取价格

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste

获取价格

2016/2/25 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

获取价格

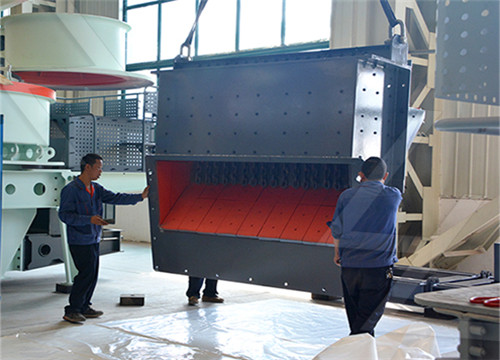

Crusher Hammers / Hammer Heads. Material: Alloy steel, high manganese steel, cast steel and high chromium cast iron bimetal composites, etc. Processing Technique: Forging or casting. Application: The crushing of

获取价格

2022/2/14 The paper shows the preparation of the numerical models necessary for the simulation mapping of industrial-scale crushers of problematic material, such as copper ore with complex lithology. The

获取价格

The material passes through the feed opening into the striking arc of the rotating hammers. The hammers fling the material against the grinding ledges of the grinding wall, from where it rebounds back against the hammers.The material flow is spread over the following discharge grates, where the product granulometry is separated and discharged through

获取价格

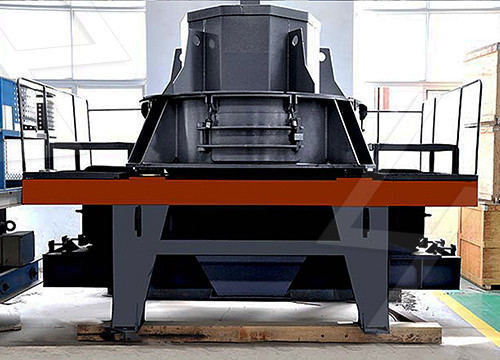

2014/9/23 Any material fed to the crusher must be pre-sized for that particular crusher (usually 200mm or less). In addition, the cone crusher will not produce a consistent cubical product, which is a key requirement in many material specifications. Finally, these units, like jaw crushers, are not suitable for handling any clay or metal mixed in with the ...

获取价格

The Hammer crusher hammer head is arranged on the hammer crusher rotor shaft, hammer crusher in high-speed direct blow materials, finally break into suitable material particle size. Hammer crusher hammer head is applicable to the cement, chemical, electric power, metallurgy and other industrial sectors crushing medium hardness materials,

获取价格

1.1 Advantages and disadvantages of hammer crusher Advantages of Hammer Crusher. 1-simple structure. 2-compact size. 3-small weight. 4-small power consumption. 5- high productivity. 6-Large crushing ratio. 7-small and uniform size product. 8-Less over crusher material. 9- continuous and reliable work. 10-easy maintenance and repair

获取价格

2023/6/21 Several key factors must be considered when selecting the best material for crusher hammers in clinker applications: Wear Resistance: Clinker is highly abrasive, subjecting crusher hammers to significant wear. Opting for a material with excellent wear resistance is essential to prolong hammer life and minimize downtime.

获取价格

2021/10/4 In industry, crushers are used to destroy brittle materials by compression (roll, jaw, cone) and impact (gear, hammer). Therefore, the properties of crushing at the level of quantitative estimates and characteristics have been studied for these two types of destructive action [].Compression crushers, widely used in the metallurgical industry, are

获取价格

2023/6/25 Hammer crusher is a widely used crushing machinery in cement, ceramics, mining, electric power, and other industries, the crusher hammers are its main wear parts, for a long time more high manganese steel manufacturing, when the impact on the crushed material is not strong, high manganese steel with work-hardening properties

获取价格

2023/3/11 Another advantage of using an impact crusher is that it has a relatively low operating cost. The machine uses less energy than other crushers, such as jaw or cone crushers, and its impact force is more efficient at breaking down the material, resulting in less energy waste. However, there are some limitations to the use of impact crushers.

获取价格

Home » Crusher Liners » HSI Material Selection. Blow Bar and Hammer Material Selection. CMS Cepcor® stock horizontal shaft impact crusher hammers and blow bars manufactured in the EU in various premium material grades to suit all applications:. Manganese Steel. Manganese hammers and blow bars are commonly used primary

获取价格

It is vital that you know, as accurately as you can, the size distribution of the raw material. The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher. Sampling is a vital part of ...

获取价格

2024/7/15 Hammer crusher price: It has many models with the lowest price of $976. Among them, the heavy hammer crusher has a larger granularity and is sold $5, 000-$180, 000. Hammer crusher can form a single production line to achieve one-time molding, which can simplify the crushing process and save 40% of the cost. 3. Different in structure

获取价格

2023/3/11 Another advantage of using an impact crusher is that it has a relatively low operating cost. The machine uses less energy than other crushers, such as jaw or cone crushers, and its impact force is more

获取价格

Home » Crusher Liners » HSI Material Selection. Blow Bar and Hammer Material Selection. CMS Cepcor® stock horizontal shaft impact crusher hammers and blow bars manufactured in the EU in various premium

获取价格

It is vital that you know, as accurately as you can, the size distribution of the raw material. The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any

获取价格

2024/7/15 Hammer crusher price: It has many models with the lowest price of $976. Among them, the heavy hammer crusher has a larger granularity and is sold $5, 000-$180, 000. Hammer crusher can form a single production line to achieve one-time molding, which can simplify the crushing process and save 40% of the cost. 3. Different in structure

获取价格

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of

获取价格

IN-SERVICE PERFORMANCE OF HIGH-MANGANESE STEEL CLINKER CRUSHER HAMMER Abhinav Karanam and Ron Birnie-Browne Unicast Inc, Kelowna, BC, Canada ... Composition of as-cast materials. Composition Fe C Mn Cr Mo Si S P ASTM A128 Gr. C Bal. 1.05 – 1.35 11.5 – 14.0 1.5 – 2.5 —— 1.00 max 0.07 max

获取价格

2024/4/19 Impact crushers and hammer mills work with it. In impact crushers, the material is hit by rotating hammers or blow bars, as a result it breaks up into smaller pieces. This method is preferable in the case of less abrasive materials, such as limestone, dolomite, and soft to medium hard rocks. The high-speed impact forces can wear down

获取价格

2021/6/14 The jaw crusher is one of the most admired and most sought after equipment from the house of Propel Industries. For the benefit of newcomers in the industry, here is an explainer of the various components of the Jaw crusher. A jaw crusher consists of Crusher Body Pitman Jaw plate Rear end frame Eccentric shaft

获取价格

For medium – hard to hard materials impact crushers and hammer crushers are more suitable; they achieve size reduction mainly by impact. In average the energy consumption for crushing is 2.5 kWh /ton. CRUSHERS TYPES ¨ Hammer crushers. ¨ Impact crushers. ¨ Jaw crushers. ¨ Gyratory crushers (cone crusher). ¨ Roller crushers. Hammer Crushers

获取价格

Roller crusher diagram Hammer mills and impact crushers. One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing.

获取价格

2021/4/1 Hammer crusher: Abrasive wear and tribocorrosion. Garmeh et al. [13] Hadfield Steel (Fe–18.0Mn–125C–0.6Si–<0.75Cr) In service: Hammer crusher: Carbide-formation and the lack of mechanical and tribological properties at the operating temperatures (200 °C – 400 °C). Albertin and Sinatora [14] High chromium cast iron

获取价格

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

获取价格

Features of the Williams Slugger Crushers. Williams Slugger Hammer Mill Crushers are an ideal choice for applications requiring a large feed opening. This type of hammer mill crusher is suitable for continuous jobs with either an hourly output or reduction ratio. There are many features of these slugger crusher hammer mills, including:

获取价格

2024/7/17 Hardness: Hard materials like granite and basalt are suitable for jaw crushers or gyratory crushers, while softer materials like limestone and coal can opt for impact crushers or hammer crushers. Abrasiveness: Materials with high abrasiveness like iron ore require crushers with good wear resistance, such as cone crushers.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين