2023/11/1 The authors equipped the laboratory-scale planetary ball mill (Retsch PM400) with a rig that allows moving the camera along the rotation of the mill ...

获取价格

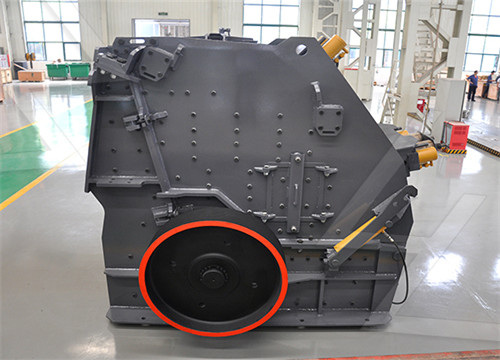

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls. An internal cascading effect reduces the

获取价格

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is

获取价格

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material

获取价格

2011/4/10 The phase transformation of a silica-rich iron ore during planetary milling has been studied. A mixture of silica-rich low grade iron ore and iron powder (4.75

获取价格

Download. The PM 400 is a robust floor model with 4 grinding stations and accepts grinding jars with a nominal volume from 12 ml to 500 ml. It processes up to 8 samples simultaneously which results in a high

获取价格

Metal Oxide (including iron ore). Fibrous Materials: Paper, Fiber Products, Cellulose, and Polymers. Miscellaneous: Coke, Coal, Ceramics, ... Planetary Ball Mill 5. ITEM BM40

获取价格

Download. The Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml. This setup allows for processing up to 2 x 220 ml sample material per

获取价格

2023/8/1 Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrial-scale ball mills. R. Carvalho T. Campos Patricia M. C. Faria L. M.

获取价格

Download scientific diagram Internal structure of the planetary ball mill from publication: On the grinding effects of high-silicon iron tailings The main chemical component of high-silicon ...

获取价格

The Planetary Ball Mill PM 300 is a powerful and ergonomic benchtop model with two grinding stations for grinding jar volumes up to 500 ml. This setup allows for processing up to 2 x 220 ml sample material per batch.

获取价格

The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml. The extremely high centrifugal forces of Planetary Ball Mills result in

获取价格

DOI: 10.1016/j.powtec.2023.118901 Corpus ID: 260880828; Mechanistic modeling and simulation of a wet planetary ball mill @article{Rodriguez2023MechanisticMA, title={Mechanistic modeling and simulation of a wet planetary ball mill}, author={Victor A. Rodriguez and Luciane Ribas and Arno Kwade and Lu{\'i}s Marcelo Tavares},

获取价格

The following table mentions the results of grinding with reference to time of grinding rpm of the Planetary Ball Mill (PBM-07): Granite Samples (Hardness 5 – 6 mhos scale) RPM: 260: Grinding Time for primary cycle ... Iron Ore Samples (Hardness 5 – 6 mhos scale) RPM: 240: Grinding Time for primary cycle: 20 mins: Dia.20 mm (7 Nos),Dia ...

获取价格

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of medium-hard, soft, brittle, fibrous, temperature-sensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding ...

获取价格

High quality 4L Dual Planetary Ball Mill Wet / Dry Grinding For Iron Ore Silicon Powder from China, China's leading 4L Dual Planetary Ball Mill product, with strict quality control Dual Planetary Ball Mill factories, producing high

获取价格

Planetary mills with a single grinding station require a counterweight for balancing purposes. In the planetary ball mill PM 100 this counterweight can be adjusted on an inclined guide rail to compensate for the different heights of the centers of gravity of differently-sized grinding jars and thus avoid undesired oscillations of the machine.

获取价格

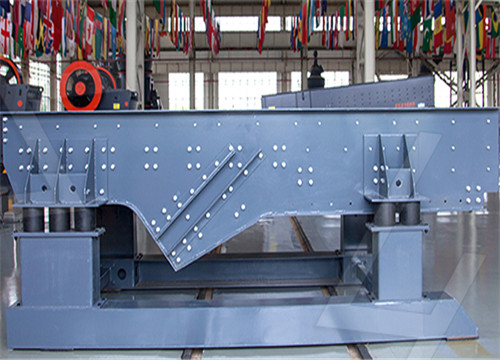

The IsaMill™, as shown in Figure 8.15, is a horizontal stirred mill consisting of a series of 7–8 rotating grinding disks mounted on a cantilevered shaft that is driven through a motor and gearbox. The disks operate at tip speeds of 21–23 m/s, resulting in energy intensities of up to 300 kW/m 3.The mill is filled with suitable grinding media, and the space between

获取价格

2024/7/12 Some of the most common types include tumbling ball mills, planetary ball mills, and vibratory ball mills. A conical ball mill, known for its efficiency in grinding, operates with changes in ball size and kinetic energy as the discharge outlet is approached. ... Ore Processing. In ore processing, mills are used to grind and blend materials for ...

获取价格

High quality 4L Dual Planetary Ball Mill Wet / Dry Grinding For Iron Ore Silicon Powder from China, China's leading 4L Dual Planetary Ball Mill product, with strict quality control Dual Planetary Ball Mill factories, producing high

获取价格

DOI: 10.1016/J.POWTEC.2021.07.030 Corpus ID: 237666917; Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrial-scale ball mills @article{Carvalho2021MechanisticMA, title={Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrial-scale ball mills}, author={Rodrigo M

获取价格

Planetary Mills are ideally suited for fine grinding of hard, medium-hard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the high-energy impact of grinding balls in rotating grinding bowls.

获取价格

The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, time setting according to experimental needs, so as to improve efficiency of grinding. ... PTFE mill jar: Iron ore materials with lower impurity ...

获取价格

A Planetary Ball Mill for rapid fine crushing of soft, hard, brittle and fibrous material to end fineness <1µm Quick and easy to clean fine crushing Easy exchange of grinding jars and balls Grinding jars and balls made from a wide range of materials available Grinding jar volume up to 500cc Progr. control End fineness < 1µm CE-certified Planetary Ball Mills

获取价格

DOI: 10.1016/J.POWTEC.2021.07.030 Corpus ID: 237666917; Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrial-scale ball mills @article{Carvalho2021MechanisticMA, title={Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrial-scale ball mills}, author={Rodrigo M

获取价格

Planetary Mills are ideally suited for fine grinding of hard, medium-hard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the high-energy impact of grinding balls in rotating grinding bowls.

获取价格

The planetary ball mill has functions of timing power off, self-timing forward and reversal rotating. You may choose freely any operation modes of one-way direction, alternation, succession, time setting according to

获取价格

A Planetary Ball Mill for rapid fine crushing of soft, hard, brittle and fibrous material to end fineness <1µm Quick and easy to clean fine crushing Easy exchange of grinding jars and balls Grinding jars and balls made from a wide range of materials available Grinding jar volume up to 500cc Progr. control End fineness < 1µm CE-certified Planetary Ball Mills

获取价格

bonded agglomerates in a ball mill [14]. It was concluded that the computational simulations were a significant tool for analyzing the breakage and flow in ball mill. Bumeister et al. [15] determined the stressing conditions of dry grinding in planetary ball mills through DEM approach involving the contact model of Hertz and Mindlin.

获取价格

2011/4/10 The phase transformation of a silica-rich iron ore during planetary milling has been studied. A mixture of silica-rich low grade iron ore and iron powder (4.75 wt.%) was subjected to high energy ball milling and the resulting products were characterized at various milling times.The major constituents of the silica-rich iron ore

获取价格

2015/9/21 Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP). As-prepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, X

获取价格

Operation of the RETSCH planetary ball mills is particularly safe. They feature a robust Safety Slider which ensures that the mill can only be started after the grinding jar has been securely fixed with a clamping device. ... coal, coke, compost, concrete, electronic scrap, fibres, glass, gypsum, hair, hydroxyapatite, iron ore, kaolin ...

获取价格

planetary ball mill. Planetary mills with a single grinding station require a counterweight for balancing purposes. In the Ball Mill PM 100 CM this counterweight can be adjusted on an inclined guide rail. In this way the different heights of the centers of gravity of differently-sized grinding jars can be compensated in order to avoid

获取价格

2015/6/19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and

获取价格

2017/2/13 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for

获取价格

2023/8/30 In addition to comminution, you can use Planetary Mills for mixing and homogenizing of emulsions and pastes or for mechanical alloying and activation in materials research. How does Ball Mill Work? Materials used to grind include iron ore and ceramics are added to the ball mill. It rotates either on its vertical or horizontal axis and bounces ...

获取价格

planetary ball mill. Planetary mills with a single grinding station require a counterweight for balancing purposes. In the Ball Mill PM 100 this counterweight can be adjusted on an inclined guide rail. In this way the different heights of the centers of gravity of differently-sized grinding jars can be compensated in order to avoid disturbing

获取价格

Planetary Ball Mill BM40 is suitable for grinding(dry\wet) and mixing some soft,hard,brittle and fibrous samples ,which are used wherever the highest degree of fineness as customer required,as well as the grinding result is reproducible. ... waste electronic products, mineral, ore, limestone, gypsum, quartz, kaoin, bones, metal oxide, iron ore ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين