nce in manufacturing jaw crushersThey are used in mines and quarries as primary crushers to crush blasted rockpile, which may have edge lengths of over 2,000 mm depending on

获取价格

2023/12/28 The PE400×600 jaw crusher is a popular choice for various industrial applications in Ghana and beyond. This versatile piece of equipment is designed to

获取价格

2024/6/12 Here, we focus on two primary models offered by Aimil Ltd.: the Jaw Crusher and the Heavy Duty Jaw Crusher. Aimil’s Jaw Crusher : Aimil’s Jaw Crusher

获取价格

2023/8/1 Gyratory crushers, invented by Charles Brown in 1877, are elegant tall devices that crush material between a conical fixed outer shell and a smaller conical

获取价格

They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than

获取价格

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel.

获取价格

Selecting the right crusher for your project can be a complex decision, given the range of available options. Each type of crusher has its own unique benefits and applications. For instance: Jaw Crushers: Ideal for heavy

获取价格

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate

获取价格

2023/12/30 In the construction industry, jaw crushers are employed to crush raw materials like granite and gravel to produce aggregates used in concrete and asphalt. Jaw crushers are integral to recycling ...

获取价格

2016/2/28 No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standard gyratory crusher and the Blake jaw crusher. Although their fields of

获取价格

2024/7/15 Jaw crusher machine installation cost is relatively higher than gyratory crusher while its investment and maintenance cost is much lower than that of gyratory crusher. ... They can be used in a variety of

获取价格

2024/2/18 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. ... This powerful action makes the jaw crusher the

获取价格

Jaw crushers Large amounts of material are fed into the “V-shaped” jaw of this crusher and are reduced using compressive force. One side of the V remains stationary while the other side of the V swings against it. ... Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone ...

获取价格

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor

获取价格

2023/2/21 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages. This comprehensive guide also provides expert tips on maintenance and selecting the right machine for your specific application.

获取价格

2019/5/30 Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney Blake) have long been the standard for crushing hard ...

获取价格

2021/3/25 Gyratory Crushers typically have a higher capital cost and require a large housing structure that can become a significant engineering investment. Jaw Crushers. Jaw Crushers are another excellent choice for primary crushing applications because they can accept the toughest, hardest, most abrasive materials. They can handle dry to

获取价格

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with over 12,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

获取价格

2024/2/5 There are mainly two types of jaw crushers: the single toggle and the double toggle (or Blake crusher). The single-toggle jaw crusher features a moving jaw suspended on the eccentric shaft. It’s known for its efficiency in crushing but tends to be more susceptible to wear because of the high motion of the jaw.

获取价格

2024/2/6 Exploring types of jaw crusher for mineral processing solutions. Find out which one suits your needs on our informative blog. Equipment ... and large-scale industrial applications, offering high capacity and robust construction to handle heavy-duty operations. The design of stationary jaw crushers focuses on durability and efficiency,

获取价格

Jaw crushers for powerful crushing across a range of applications. Essa Jaw Crushers have set the industry standard for over 30 years so you can be assured the designs have stood the test of time. They offer fast sample throughput with good reduction ratio and reduced sample contamination. ... and in industrial production facilities. The JC5000 ...

获取价格

2018/9/10 Jaw crushers. A jaw crusher is a compression type of crusher. Feed material is reduced by squeezing it between a moving piece of steel and a stationary piece of steel, with the discharge size controlled by the gap setting, ie the space between those two pieces of steel. ... The crusher application, speed and setting are the factors

获取价格

2023/9/30 Applications of Jaw Crushers in Construction. Road Construction: Jaw crushers play a crucial role in road construction projects. Rocks and aggregates are crushed to the required size, forming the base or sub-base for roads, ensuring durability and stability. ... The extracted materials are then refined and used in various industrial ...

获取价格

2024/2/6 Exploring types of jaw crusher for mineral processing solutions. Find out which one suits your needs on our informative blog. Equipment ... and large-scale industrial applications, offering high

获取价格

Jaw crushers for powerful crushing across a range of applications. Essa Jaw Crushers have set the industry standard for over 30 years so you can be assured the designs have stood the test of time. They offer fast

获取价格

2018/9/10 Jaw crushers. A jaw crusher is a compression type of crusher. Feed material is reduced by squeezing it between a moving piece of steel and a stationary piece of steel, with the discharge size controlled

获取价格

2023/9/30 Applications of Jaw Crushers in Construction. Road Construction: Jaw crushers play a crucial role in road construction projects. Rocks and aggregates are crushed to the required size, forming the base or sub-base for roads, ensuring durability and stability. ... The extracted materials are then refined and used in various industrial ...

获取价格

Industrial Heating Systems ... Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. ... mining and recycling in both primary and secondary applications. The ...

获取价格

2023/2/28 In jaw crushers, the material is fed into the crushing chamber and is crushed between a fixed jaw and a movable jaw. Gyratory crushers work by crushing materials between a mantle and a concave, while impact crushers use the principle of impact to crush the material. ... Primary crushers are also used in some industrial

获取价格

The Jaw Crusher EB series delivers the ultimate in primary crushing efficiency, and therefore lower operating costs. It achieves this through a combination of optimum speed and generously dimensioned flywheels, which allows the crusher to achieve consistently high throughputs, reducing power peaks and energy costs.

获取价格

2017/6/2 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from 20 to 100 in. are reduced to secondary crusher sizes of 1 to 20 in. or mill feed size of .5 to 3 in. ... Main Application. Jaw crushers: Soft to ...

获取价格

2021/5/6 A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point. The motion is, however, a more complex one than the

获取价格

Jaw Crushers JBC Byo, offers a wide range of Jaw Crushers from the Largest 50” x 60” down to our smallest 8” x 5” Crushers. Single Toggle Jaw Crushers Jaw crushers are normally placed as a primary crusher, reducing run of mine ore for the next stage in the crushing process. Both heavy duty and standard duty models are available, depending

获取价格

jaw crusher Concrete floor G-7 G-4 Fig. 1.Building housing primary-crushing unit. a) section; b) foundation of SMD-60A jaw crusher; c) settlement curves of column foun-dations in axes G-4 and G-7. Dynamic load Indicators harmonic pulse Peak force, kN horizontal vertical 116 138 3500-Frequency of force effect, Hz 2.08 60 Distance between point ...

获取价格

2023/12/30 In the world of material processing and mining, Jaw Crushers stand as stalwart machines, pivotal in breaking down large rocks into more manageable sizes. One of the leading names in crafting these

获取价格

Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit. Types of Jaw Crushers. Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types ...

获取价格

This jaw crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track.

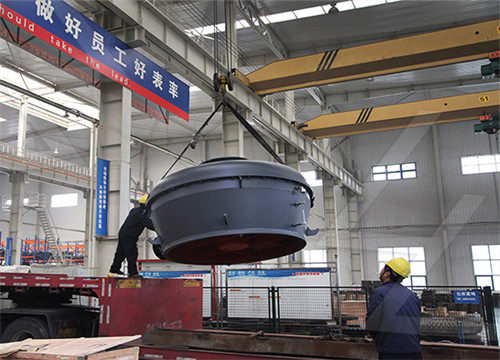

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين