As a result, the control of coal mills is one of the areas of most active research since many years and represents the main source of reduced load following capability (LFC) for the

获取价格

2023/12/1 Energy consumption in hot rolling mills is divided into two categories electric energy for driving the mill and auxiliary equipment and fuel oil energy for

获取价格

This is approximately 0.5% of total final energy consumption globally. Published information indicates that the entire mining industry consumes approximately 12 EJ per year—or 3.5% of total final energy

获取价格

2023/9/22 The mill behavior was characterized by the mill power consumption and the particle size distribution (PSD) of the milled product. Mill power increased with

获取价格

led to a reduction in fuel consumption (cost). A substantial net reduction in total costs resulted from these optimiza - tion efforts. ... (2R), one 1500 psig coal-Case study: Paper

获取价格

2023/8/22 For refinery equipment with additional emissions beyond fuel consumption (fluid ... C., Pfister, S. Hellweg, S. Global site-specific health impacts of fossil energy, steel mills, oil refineries ...

获取价格

2019/3/29 Fossil fuel combustion is the main source of energy input with a specific consumption of 3.7 GJ per kg calcine produced. ... hot gas coal mill was studied to replace existing recirculation system of coal mill off-gas. Energy recovery of 14.2 GJ/hour can be achieved with additional environmental benefit from 80.3% reduction in consumption of ...

获取价格

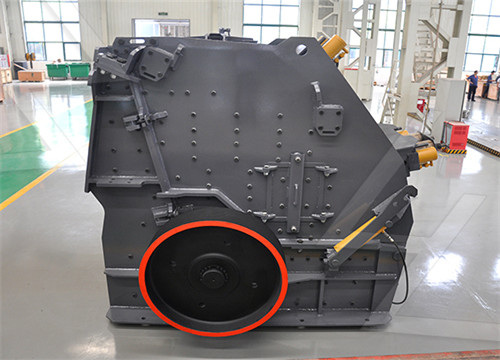

The BTM is a low-speed mill that primarily grinds coal by impact and attrition. The VRM is a medium- speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, develops shearing action as well. For both mills a constant centrifugal force is maintained. The speed

获取价格

2015/8/1 As a result, the control of coal mills is one of the areas of most active research since many years and represents the main source of reduced load following capability (LFC) for the coal fired thermal power plants [4]. Simple control is also responsible for high fuel consumption, poor dynamic response, and high operating cost.

获取价格

End Use of Fuel Consumption - The Manufacturing Energy Consumption Survey (MECS) collects fuel consumption by end use for six major energy sources – electricity, natural gas, coal, LPG, diesel/distillate, and residual fuel oil. Coke, an energy source used for fuel in a blast furnace, is not included as one of the six major energy sources when collecting

获取价格

2012/11/17 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance.

获取价格

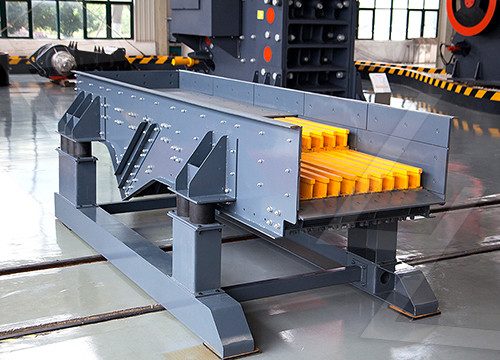

Table 2 is a summary of the milling energy consumptions of hammer mill for four biomasses with different moisture contents [31]. Considering the energy consumption and fuel size together, milling ...

获取价格

2017/11/15 The unit energy consumption is a sum of energy consumption of the pulveriser e pm and its fan e pw. ... All costs related to the supply of fuel to the mills have to be included in the value of c f, which is the coal cost per unit, PLN/Mg.

获取价格

The unit energy consumption is a sum of energy consumption of the pulveriser epm and its fan epw. The value of ep for a given mill type changes according to the characteristic of grinded coal and to the PF quality. From measurements [14,

获取价格

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW's pulverizers, found at power stations throughout the world.

获取价格

2023/5/22 Conventional mono-channel burner, semi direct coal firing system, leakages at kiln outlet, low kiln inlet riser capacity, inefficient coal mill bag filter, coal dosing system, cooler with entire moving grate and high specific heat consumption are some of the identified challenges in achieving high TSR.

获取价格

reductions of about 60% in energy required to produce a tonne of crude steel since 1960, as demonstrated in Figure 1.1 Figure 1: Indexed global energy consumption/tonne of crude steel production worldsteel, with the help of its members, has developed a comprehensive and process specific energy benchmarking

获取价格

Manufacturers have two types of energy consumption—fuel and nonfuel. Fuel consumption is the use of any substance that can be burned to produce heat and power or to generate electricity. ... production in the pulping process to make paper and the subs equent use of the produced black liquor as a fuel at pulp and paper mills. U.S. Energy ...

获取价格

1999/5/31 Peter W. Huber and Mark Mills Forbes. Southern California Edison, meet Amazon. Somewhere in America, a lump of coal is burned every time a book is ordered on-line. The current fuel-economy rating: about a pound of coal to create, package, store and move 2 megabytes of data. The digital age, it turns out, is very

获取价格

2023/5/22 Conventional mono-channel burner, semi direct coal firing system, leakages at kiln outlet, low kiln inlet riser capacity, inefficient coal mill bag filter, coal dosing system, cooler with entire moving grate and high specific heat consumption are some of the identified challenges in achieving high TSR.

获取价格

reductions of about 60% in energy required to produce a tonne of crude steel since 1960, as demonstrated in Figure 1.1 Figure 1: Indexed global energy consumption/tonne of crude steel production worldsteel, with the help of its members, has developed a comprehensive and process specific energy benchmarking

获取价格

Manufacturers have two types of energy consumption—fuel and nonfuel. Fuel consumption is the use of any substance that can be burned to produce heat and power or to generate electricity. ... production in the pulping process to make paper and the subs equent use of the produced black liquor as a fuel at pulp and paper mills. U.S. Energy ...

获取价格

1999/5/31 Peter W. Huber and Mark Mills Forbes. Southern California Edison, meet Amazon. Somewhere in America, a lump of coal is burned every time a book is ordered on-line. The current fuel-economy rating: about a pound of coal to create, package, store and move 2 megabytes of data. The digital age, it turns out, is very

获取价格

2022/5/9 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is ...

获取价格

2015/8/1 Simple control is also responsible for high fuel consumption, poor dynamic response, and high operating cost. Further, the mill performance and availability is also influenced by some common mill faults like mill choking, coal hang up in mills, fire or explosion, and wear in the milling components such as rollers, grinding table, and vanes

获取价格

Energy efficiency in a cement plant is measured as a combination of two factors, viz., Thermal Energy Consumption and (2) Electrical Energy Consumption. ... The average annual fuel energy requirement of a representative state of the art cement kiln based on theoretical modelling and empirical data is estimated between 3,000 to 3,400 MJ/t ...

获取价格

2011/8/1 Now suppose this same pulverizer must grind sufficient coal flow to produce full load on the boiler with fuel that is 40 HGI, still 3/4-inch maximum size with 7% moisture, but with an increased ...

获取价格

2012/12/1 The electric arc furnaces and the reheat furnaces are the major energy consumers, having specific energy consumption of 502 and 342 kWh/t; their thermal efficiencies are 50 and 62%, respectively.

获取价格

2013/3/1 The higher value in India is partly due to the harder raw material and the poor quality of the fuel [23]. The specific energy consumption of the rolls increases linearly with the increase in applied grinding ... The primary air supply being decoupled from the coal mill in multi-channel designs, only 7–12% of stoichiometric air is used for ...

获取价格

With these reductions in energy consumption in mind, this study aims to accomplish the following: 1. Explain how the historical reduction in energy consumption was achieved and offer guidance for the future. 2. Compare current average energy consumption figures with those for good practices. 3.

获取价格

2021/10/28 IHI developed a wood pellet mill which equipped some devices to the coal mill. By modifying one coal mill in a commercial power plant to the pellet mill, grinding wood pellet was succeeded, and co ...

获取价格

2020/10/28 There are two types of mills and both have differing energy requirements. An ‘integrated’ mill includes pulping and paper manufacturing, and uses twice as much energy as a mill of the same size that brings in ‘market pulp.’ Market pulp is pulp that’s brought in from another location and sold as a raw material. 1. Conventional Boilers

获取价格

The cement industry, as a traditional high power consumption industry, power consumption in the cement grinding process takes a large ratio in the whole production, electric power consumption is about 60%-70% of the total consumption. With more and more strict Energy conservation and environmental protection policy published, excess

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين