A rock crusher production and operation cost is the sum total of direct and indirect costs incurred in producing a rock crusher. Direct costs include materials, labour, and overhead expenses while indirect costs include machine wear, depreciation, and transportation.

获取价格

2016/1/10 Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then

获取价格

Higher energy costs. Often there is a justifiable case to spend additional capital dollars for the better machine. When evaluating crushing equipment suppliers, crusher

获取价格

2017/3/30 Labor time to perform normal maintenance. Special or unique tools required. When the above costs are all accounted for, they are used to quantify the

获取价格

The result is a new production cost‐model to calculate the cost for producing in the comminution industry. It indicates an improved tool to get a more precise result for cost

获取价格

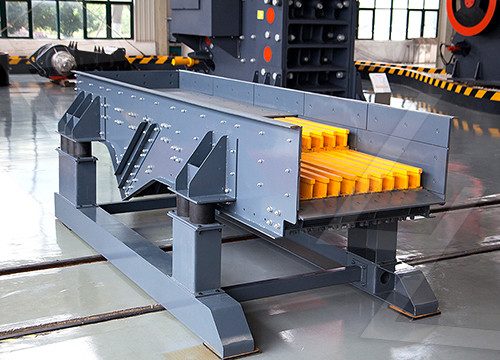

Crusher plug 160 2% of production time Chute plug 200 2.5% of production time ... It goes without saying that clean plants have lower operating costs. Crushers, screens

获取价格

2018/12/12 where c T is the operating cost of the truck ($/h). 2.1.5 Crushing cost. As crushing is the last chain of interrelated subsystems affected by mean fragmentation size, it should be included in the cost

获取价格

Rock crusher types and operating costs. When it comes to rock crushers, there are several types to consider, each with its own unique characteristics and operating costs.

获取价格

2016/1/11 The figures must be regarded only as a rough guide to the average costs of modern installations ; they are direct costs and include no overhead charges. It is

获取价格

Cost of Labour (3 people @$20.00 per hour) $60.00 per hour + Lost Revenue (250 TPH x $2.50 per Ton) $625.00 per hour = $685.00 Per Hour. Based on a 12 hour production day, this translates to a daily cost of downtime of $8,220 if you have no downstream processes the crusher feeds. Do you get better production? Different sell price for your gravel?

获取价格

Superior’s Patriot Cone Crusher is an American-made, bushing-style rock crusher that sets the standard for productivity and durability. With a lifetime warranty and high-grade, industry-exceeding components, the Patriot

获取价格

production is concentrated to jaw crushers and cone crushers. 1.1.3.2 Process Flow The process flow described in figure.. is a typical process flow built up by a

获取价格

2023/8/28 Proper sizing and selection of cone crushers are essential to maximize productivity and efficiency in aggregate and mining operations. Cone crushers are indispensable crushing machines, but their output capacity depends heavily on making the right design choices.Here are some factors to consider: Consider The Type Of Material

获取价格

To optimize operating costs and improve the product shape it is recommended that cone crushers are always be choke fed, meaning that the cavity should be as full of rock material as possible. This can be easily achieved by using a stockpile or a silo to regulate the inevitable fluctuation of feed material flow.

获取价格

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce ... the SAG mill and ball mill are considered grinders rather than crushers. In operation, the raw ... and additional costs in lost production. The advance of hydraulic relief systems has greatly reduced downtime ...

获取价格

2024/1/22 For example, a 40- x 51-in. jaw crusher calls for a maximum feed size of 32-in., a CSS range of 4- to 8-in.; and produces a desired product size that fits within that CSS range. While various crusher sizes have similar CSS range spans, some crushers operate in a bit tighter CSS range than others.

获取价格

2023/4/28 The cone crusher is a popular rock crusher in mining operations, aggregate production, and recycling applications. Many users use it for size reduction and shaping of precious metals (e.g. gold, silver, and palladium), concrete, and hard rock. ... Symons cone crusher has low operating costs and stable performance, which is

获取价格

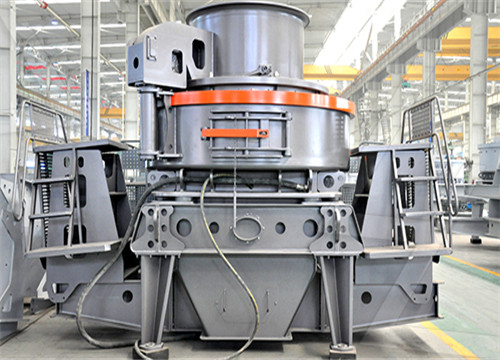

2023/8/21 You need an efficient rock crusher for crushing stones, concrete, gravel, or other materials. Impact crushers use high-speed impact forces instead of compression to crush material. There are key differences between horizontal shaft impact (HSI) and vertical shaft impact (VSI) crushers, and understanding them will help you select the best impact

获取价格

2020/2/8 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

获取价格

Silica content in your rock is a driver for material abrasivness. Feed size describes the largest input piece dimension diameter. Material hardness has a significant affect on crusher performance it doesn't exclude an impact crusher from processing hard rock. The harder to rock gets the smaller the feed size needs to be to avoid damages.

获取价格

JXSC small portable rock crushers are suitable for crushing various rocks, aggregates and ores. ... This eliminates the need for multiple trips between the production site and the stationary crusher, saving time and costs. With its efficient operation and adjustable settings, this small portable crushing plant delivers reliable performance even ...

获取价格

So many industries rely on crushed rock for their everyday operations, such as: Construction: ... accounting for as much as 15% of our crushed stone production. ... For most aspiring rock crushers, the cost of purchasing a new rock crusher is one of the biggest barriers to entry. Look for a company like Senya Crushers that produces high ...

获取价格

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment. Stationary crushers include jaw crushers, impact

获取价格

Silica content in your rock is a driver for material abrasivness. Feed size describes the largest input piece dimension diameter. Material hardness has a significant affect on crusher performance it doesn't exclude an impact crusher from processing hard rock. The harder to rock gets the smaller the feed size needs to be to avoid damages.

获取价格

JXSC small portable rock crushers are suitable for crushing various rocks, aggregates and ores. ... This eliminates the need for multiple trips between the production site and the stationary crusher, saving time and costs. With its efficient operation and adjustable settings, this small portable crushing plant delivers reliable performance even ...

获取价格

So many industries rely on crushed rock for their everyday operations, such as: Construction: ... accounting for as much as 15% of our crushed stone production. ... For most aspiring rock crushers, the cost of purchasing a new rock crusher is one of the biggest barriers to entry. Look for a company like Senya Crushers that produces high ...

获取价格

Mining operations use different kinds of crushers so selecting the appropriate crusher is important for every operation. Understanding the stages of crushing process and the types of crushers that best fit each stage can simplifies your equipment selection. Each type of crusher is different and used to achieve a certain end result.

获取价格

2023/1/16 There are different types of rock crushers to choose from. Here is the guide explaining machines best for specific projects. ... They are often used in heavy mining operations, where large rocks need to be reduced to smaller sizes quickly and efficiently. ... Production costs will also typically be much lower when using rock crushers than

获取价格

Maximum productivity Eastman Jaw crushers are engineered to deliver maximum productivity at the lowest operating costs. It is the best alternative to primary gyratory crushers, process the hard material efficiently. High crushing capability Jaw crushers are designed to process abrasive hard rock, with aggressively-shaped nip angle, it featurs

获取价格

® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and mining operations on secondary, tertiary or quaternary crushing stage. It is designed for high productivity, low operating and wear costs, long service life and high efficiency, providing high quality product.

获取价格

Experience increased efficiency while saving on the costs of outsourcing your crushing services. Your job site will be equipped to crush all kinds of materials, including rocks, stone and concrete. ... The rock crushers of Senya are widely used for the primary, secondary and tertiary hard-rock crushing, including Cone Crusher, Vertical Shaft ...

获取价格

2023/2/28 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite Mobile Crushing Plant; 100t/h Slag Mobile Crushing Plant; Blog; About; ... Choosing the right type of primary crusher for your operation depends on several factors, including the maximum size of the material to be crushed, the desired output size, and the capacity of the crusher ...

获取价格

2023/2/24 Learn about the factors that affect the setup cost of a stone crusher plant, get an estimate of the cost, and explore ways to reduce the cost. ... the cost of setting up the plant. The closer the plant is to the source of raw materials, the lower the transportation cost will be. Type of rock: ... 200t/h Pebble Crushing Mobile Production Line ...

获取价格

Once installed, the stationary crushing plants have low maintenance and operating costs. Application. ... forming a comprehensive production system. The rock crusher portable can be moved between different locations and are

获取价格

2018/12/12 where c T is the operating cost of the truck ($/h). 2.1.5 Crushing cost. As crushing is the last chain of interrelated subsystems affected by mean fragmentation size, it should be included in the cost analysis. Crusher cost varies with the particle size of the feed. The crushing cost is calculated based on specific energy.

获取价格

2024/4/19 Nevertheless, gyratory crushers are usually more expensive, need more intricate foundation and have higher operating and maintenance costs as compared to jaw crushers. The decision of a jaw crusher or a gyratory crusher is based on, for instance, the required output size, production capacity, and the available budget.

获取价格

2024/6/28 Consult experts when choosing a rock crusher. Consider factors such as cost, mobility, purpose, size, and quality. ... Screening equipment is essential in tertiary crushing operations. Large materials can occupy space and consume energy, causing delays and increasing costs. ... Portable rock crushers provide production flexibility

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين