2024/4/26 These processes involve breaking down the mined ore into smaller fragments and separating it based on size. Let's explore the crushing and screening stages in more detail: 1. Crushing. Crushing is

获取价格

2023/12/1 1. Introduction. Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and

获取价格

2023/12/19 Iron ore is generally sourced from open pits on the planet’s surface and typically requires only crushing before it is ready for the smelter. Like most mining, It all starts with a bang. Iron ore and its

获取价格

but unwanted ore constituents, separation of the metal atoms from the compounds in which they occur, and purification of the resulting metals. 10.2 PHYSICAL AND CHEMICAL

获取价格

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of

获取价格

2022/10/20 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and

获取价格

2016/8/24 Iron ore processing. This special issue of Mineral Processing and Extractive Metallurgy presents a selection of the best metallurgy papers delivered at the

获取价格

The iron ore processing industry produces usable concentrations of iron-bearing material by removing nonferrous rock (gangue) from low-grade ore. In the United States,

获取价格

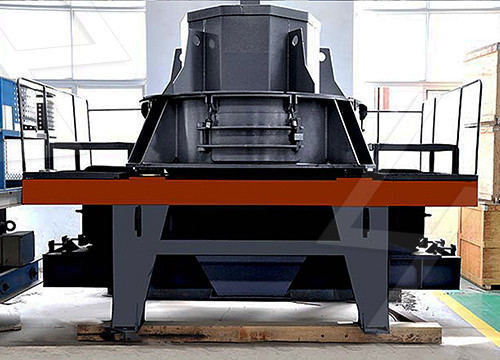

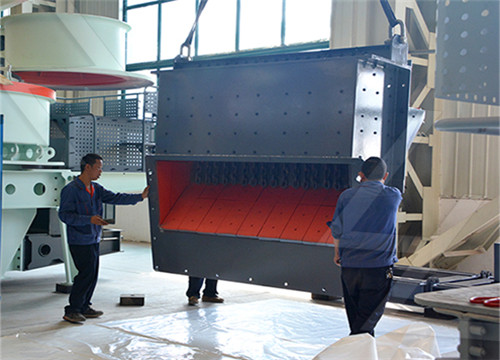

Iron ore processing flow. The first stage: crushing screening – three stage closed-circuit crushing. Large pieces of iron ore are uniformly sent to the jaw crusher or coarse crushing mobile station by the vibrating feeder for

获取价格

2023/6/30 The iron in the chalcopyrite ends up converted into an iron(II) silicate slag which is removed. Most of the sulfur in the chalcopyrite turns into sulfur dioxide gas. This is used to make sulfuric acid via the Contact Process. An overall equation for this series of steps is: \[2CuFeS_2 + 2SiO_2 +4O_2 \rightarrow Cu_2S + 2FeSiO_3 + 3SO_2 \label{1} \]

获取价格

2023/12/19 But How is Iron Ore Mined? Iron ore mining is relatively simple compared to other minerals and metals that require underground tunnels and complex chemical-drive processes, like gold. Iron ore is

获取价格

Iron ore is a rock or mineral from which metallic iron can be extracted economically. It constitutes 5% of the earth’s crust. Viable forms of ore contain between 25% and 60% iron. ... Granite-linked deposits that

获取价格

2017/10/17 Smelting Reduction. Figure 2: The smelt reduction vessel (SRV) is the core technology component of the Hismelt process. Source: RioTinto While years of ironmaking technology innovations have optimized blast furnace productivity, two alternative processes—smelting reduction and direct iron reduction— are growing in adoption. The

获取价格

2023/7/12 Figure \(\PageIndex{2}\): Three Common Ores. (left) Iron ore, (middle) Manganese ore – psilomelane, and (right) Lead ore – galena and anglesite. ... Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a

获取价格

Iron ore; Answer . This question lists many different substances involved in the extraction of iron. The extraction of iron occurs inside a blast furnace, a large 40 m tall steel tower. The waste gases produced from this process are carbon dioxide and nitrogen, neither of which is known as coke.

获取价格

2023/6/30 This page looks at the use of the Blast Furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various kinds of steel. Contributors and Attributions. Jim Clark (Chemguide.co.uk) Prof. Robert J. Lancashire (The Department of Chemistry, University of the West Indies)

获取价格

By 2000 bc the process of purifying gold-silver alloys with salt to remove the silver was developed. The mining of alluvial deposits and, later, lode or vein deposits required crushing prior to gold extraction, and this consumed immense amounts of manpower. By ad 100, up to 40,000 slaves were employed in gold mining in Spain. The advent of ...

获取价格

2023/5/7 Description and properties of common iron ore minerals. Iron ore minerals are rocks or minerals that contain iron in concentrations high enough to be economically extracted. Common iron ore minerals include: Hematite (Fe2O3): Hematite is the most abundant and important iron ore mineral. It is typically steel-gray to black in color and

获取价格

2023/9/18 Alternatively, call us on 1300 241 620 to speak to our experts today and learn all about the mining iron ore process. Types Of Iron Ore In Australia. Australia is a country that boasts a rich amount of iron ore, and several types are extracted and processed to meet both domestic and international demands. Let’s discuss the primary

获取价格

2020/9/18 For the beginner looking to get a basic handle on the pre-modern iron-production process, I think D. Sim I. Ridge, Iron for the Eagles: The Iron Industry of Roman Britain (2002) ... drainage or ore extraction. Large iron mines of this sort could have several thousands of workers doing this, but smaller operations were also common;

获取价格

Carbon monoxide reduces the iron(III) oxide in the iron ore to form iron This will melt and collect at the bottom of the furnace, where it is tapped off; iron(III) oxide + carbon monoxide → iron + carbon dioxide. Limestone (calcium carbonate) is added to the furnace to remove impurities in the ore

获取价格

While higher prices can be obtained for high-grade iron ore, the extraction of low-grade iron ore is becoming increasingly uneconomic owing to falling prices. ... the process steps comprise “Mine-Crush-Screen-Sell” and are also described as DSO process (DSO = high-grade direct shipping ore). On account of the low process costs, DSO ores ...

获取价格

Aug 02, 2021The Iron and Steel Company is the first of its kind working in the field of extracting iron ore and manufacturing iron and steel in Egypt using blast furnace technology. The company produces iron and steel products, shaped, half-formed and raw, such as iron sectors, hot flats, cold flats, billets, and base cast iron.

获取价格

2020/9/18 For the beginner looking to get a basic handle on the pre-modern iron-production process, I think D. Sim I. Ridge, Iron for the Eagles: The Iron Industry of Roman Britain (2002) ... drainage or ore

获取价格

Carbon monoxide reduces the iron(III) oxide in the iron ore to form iron This will melt and collect at the bottom of the furnace, where it is tapped off; iron(III) oxide + carbon monoxide → iron + carbon dioxide. Limestone

获取价格

While higher prices can be obtained for high-grade iron ore, the extraction of low-grade iron ore is becoming increasingly uneconomic owing to falling prices. ... the process steps comprise “Mine-Crush-Screen-Sell” and are

获取价格

Aug 02, 2021The Iron and Steel Company is the first of its kind working in the field of extracting iron ore and manufacturing iron and steel in Egypt using blast furnace technology. The company produces iron and steel products, shaped, half-formed and raw, such as iron sectors, hot flats, cold flats, billets, and base cast iron.

获取价格

Explore the damaging impact the extraction of iron ore for construction has on our natural environment globally. We use cookies. ... Tailings are the waste materials that remain after the extraction of valuable minerals from an ore during the mining process. They are typically in the form of a fine-grained, slurry-like substance and are stored ...

获取价格

2022/8/10 This section deals with the types of iron and steel which are produced as a result of the steel-making process. Wrought iron: If all the carbon is removed from the iron to give high purity iron, it is known as wrought iron. Wrought iron is quite soft and easily worked and has little structural strength.

获取价格

2015/9/15 Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page

获取价格

2019/8/16 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices. The demand for new metals and materials has also arisen

获取价格

2018/10/23 The ore is Hematite, chemical name is iron III oxide, the chemical formula is Fe 3 O 4, It has a blood red colour, it is more easily reduced, Iron is from 50-60 %, place of deposits is Oasis area (western desert) and western part of Aswan.. The ore is Limonite, chemical name is Hydrated iron III oxide, the chemical formula is 2Fe 2 O 3.3H

获取价格

2022/10/4 Average ore extraction ratio (a) and iron content (b) from ordinary blasts (grey bars) in a sublevel caving mine, with detonator positions close to the collars of the blastholes and blasts with detonator positions at the midpoint of explosive charge length (green bars, data from Zhang 2005b). The numbers in brackets are the number of the

获取价格

This page looks at the use of the Blast Furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various kinds of steel. ... This section deals with the types of iron and steel which are produced as a result of the steel-making process. Wrought iron. If all the carbon is removed from the iron to ...

获取价格

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 2.5–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7].In 2019, the

获取价格

The extraction of iron from its ore is a very long and arduous process that separates the useful components from the waste materials, such as slag. What occurs in the Blast Furnace? A blast furnace is an immense steel stack lined with refractory brick, into which the concentrated iron ore, coke, and limestone are poured from the top, while a ...

获取价格

Contribute to lbsid/en development by creating an account on GitHub.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين