crushing. Stationary screens – an extensive range of complete screening solutions for scalping, closed circuit screening, fi nal sizing and de-watering. Single inclination, double, triple and horizontal models. Sand and gravel washing – to produce special quality rock

获取价格

CRUSHINGSCREENING. rsABOUT MEKAWith more than 2,000 plants in over 65 countries on 4 continents, Meka is helping to bu. RODUCTION INDUSTRYMeka was

获取价格

stock and provide spare parts close to the mining operation. Good geotechnical information is essential to crushing plant siting and design. Installing a primary crushing plant on

获取价格

Crushing and Screening Handbook is a dive into the world of rock processing and aggregates production. It goes through the main factors impacting the quality and costs of aggregates, introduces different

获取价格

2013/4/4 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size,

获取价格

2023/2/28 Stone crusher plant design is a crucial factor in the efficient operation of the crushing process. The primary goal of plant design is to achieve the desired product size and capacity while

获取价格

Plant automation systems – monitor and control all crushing, screening, storing and conveying with real-time accuracy. Maintain maximum production capacity by adjusting

获取价格

Foresight™ stations help provide optimal production levels to mining operations. Using Metso proven smart controls and equipment in combination, this allows the fully connected plant to always be

获取价格

2023/2/28 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; ... Primary and secondary crushers, screening equipment, feeding equipment, conveyor systems,

获取价格

Astec offers a broad range of mobile crushing and screening plants, including mobile cone, jaw and impactor plants, as well as a variety of mobile screening and conveying plants. Designed for jobs that require quick and easy site mobility, our mobile product lines give producers flexibility without sacrificing productivity. Engineered to excel ...

获取价格

Exciting news from our valued customer Suttle Stone Quarries Their new picking station, powered by an Omega Crushing and Screening crusher, has arrived. It is already hard at work and proving to ...

获取价格

2013/4/4 There are several considerations in designing an efficient crushing and screening plant. The first is the raw materials to be crushed. The quarry shot material should be analysed for maximum feed size, gradation, chemical composition, amount of clay, hardness and variations within the deposit or ledges. A list of product sizes needs to

获取价格

2023/2/28 Introduction: Mobile crushing plants are a game-changer in the construction industry, providing an efficient and flexible solution to meet the growing demand for high-quality aggregates. These plants have revolutionized the traditional approach to crushing and screening, making it possible to produce aggregates at the job site, thus

获取价格

Modern crushing and screening production of stone materials is a complicated technological complex with a set of operations including the delivery of raw material,

获取价格

The screening process is just as important as the crushing itself. Screens are the hub of every rock processing plant. They are used to classify materials both in different stages of the crushing process and in final product separation. Designed as a non-welded frame with adjustable vibration features for different material types

获取价格

Method Statement for the crushing of rock and or demolition material on site using a dedicated material crusher. This document is to be read in conjunction with all operating procedures supplied by the manufacturer/supplier. These will apply to the operation of crushers supplied by any other company.

获取价格

Eco-Match is a crushing and screening service provider specialising in the provision of mobile crushing and screening equipment and associated services predominantly in the mining, industrial and construction sectors. ... product sector (i.e. road base, fill, concrete stone, builders mix, etc.) within the construction market. In order to ...

获取价格

Safe operation and use of mobile jaw crushers. coal crusher operation animation - Seo Test ... Tracked Mobile Cone Crushing Plant Tracked Mobile Screening Plant; • Safe Operation of powered mobile plant and cranes in the vicinity of

获取价格

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of

获取价格

2024/3/1 A stone crushing plant is a special site where mined stones are processed into different sizes using one or various stone crushing machines (primary, secondary, and tertiary). However, the operation of a stone crushing plant is understandably complex.

获取价格

2023/6/3 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as

获取价格

Safe operation and use of mobile jaw crushers. coal crusher operation animation - Seo Test ... Tracked Mobile Cone Crushing Plant Tracked Mobile Screening Plant; • Safe Operation of powered mobile plant and cranes in the vicinity of

获取价格

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working

获取价格

2024/3/1 A stone crushing plant is a special site where mined stones are processed into different sizes using one or various stone crushing machines (primary, secondary, and tertiary). However, the

获取价格

2023/6/3 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as

获取价格

2016/7/12 Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers.. Crushing is done underground at a few large mines. In general, the jaw crusher is the most suitable primary machine, yet

获取价格

deposit. Processing operations may include crushing, screening, size classification, material handling and storage operations. All of these processes can be significant sources of PM and PM-10 emissions if uncontrolled. Quarried stone normally is delivered to the processing plant by truck and is dumped into a bin.

获取价格

Questionnaire: Stone Quarrying, Crushing, and Screening Operations Page 1 of 6 Version 1.0 . United States Environmental Protection Agency. General Air Quality Permit for New or Modified Minor Sources of Air ... A stone quarrying, crushing, and screening facility is any stationary or portable non-metallic mineral processing facility which uses ...

获取价格

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance. This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability.

获取价格

2023/2/28 450t/h Stone Mobile Crushing Plant; 320t/h Construction Waste Material Crushing Station; 250t/h Limestone Mobile Crushing Plant; ... Primary and secondary crushing are the two most common types of crushing operations. This article will explain the basics of primary and secondary crushing, their differences, and the factors that

获取价格

system, a crushing system, a screening system, and a conveying system, among others. Here is a detailed explanation of how the stone crushing plant works. 1. Feeding. The working process of the stone crushing plant starts from the feeding. The raw stone is fed into the crushing plant by means of transport equipment such as trucks or conveyor belts.

获取价格

Crushing Station Operation - Low Operation Cost cone rock crushing station at . low operation cost jaw crushing production line at. high capacity in one. hj jaw crusher is the traditional broken reliable operation; low operation cost cone stone crushing station from it is the most ideal equipment for large stone crushing and low operation cost ...

获取价格

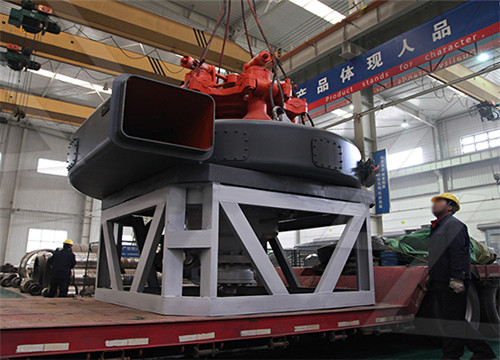

A Crushing plant is one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing and other similar operations. Crushing plants may be either fixed or mobile. A crushing plant has different stations (primary, secondary, tertiary, ...) where different crushing, selection and transport cycles are done

获取价格

A properly designed mobile crushing operation should not need any person to be present on the crusher access platform during normal crushing operations. Being on the access platform during normal operation presents the following risks: Struck by objects ejected from the crusher, such as bits of stone or metal.

获取价格

Widely used in aggregates production, recycling applications and even in some mining operations, mobile crushing and screening plants can replace stationary crushing systems, which reduces the need for hauling and thus operational costs. Lokotrack® mobile crushing and screening plants » Nordtrack™ mobile crushing and screening plants »

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين