2020/6/3 Most cone crushers have a feed opening size of 5-14", so material that's larger than the maximum size allowable will need a first

获取价格

2023/2/15 The short head cone crusher is commonly used in the mining and aggregate industries for crushing smaller volumes of material. ... Furthermore, mobile cone crushers are often designed to work in

获取价格

2023/11/22 The short head design allows for a larger crushing chamber, which can improve the efficiency of the crusher. The short head cone crusher works by rotating

获取价格

2018/4/19 The device in Fig. (14) works by constantly trying to reduce the machine’s setting according to a program, thereby maximizing power drawn within preset limits. If the crusher overloads, it opens up

获取价格

2024/4/19 A short-head cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm. A fine cone crusher, also known as a

获取价格

How CMB Cones Crushers Work. CMB Cone Crushers feature a lower mainframe housing the main shaft, an upper frame supporting a concave bowl assembly and a tapered wedge assembly machined to correspond with the inner tapered surface of the main frame. ... Re-metalling is carried out with the crushing head in situ. The short shaft configuration ...

获取价格

The 911MPEPYB600 is a small (24") diameter cone crusher is perfect for fine, secondary crushing in small operations. Ideal to re-crush rock discharging from a primary jaw crusher. Feed this short head cone crusher up to 35 mm (1.5") with a CSS closed side setting 3mm (1/8") to obtain a P80 crushed product in the 3 to 13mm (1/8" to 1/2") range. When

获取价格

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. ... The Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the ...

获取价格

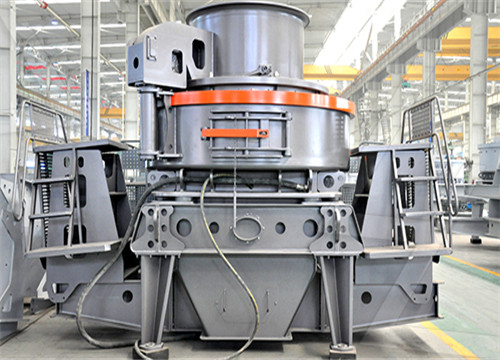

2023/5/3 Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material through squeezing, bending, shearing, and impacting. ... which can be classified into standard type and short head type, or standard type, intermediate crushing type,

获取价格

2023/7/31 A cone crusher is crucial, especially in aggregates and mining industries. It plays a role in crushing hard rocks into smaller rocks for further processing. Understanding how a cone crusher operates is essential to optimize its performance to achieve effective crushing. This article will delve into the components of the cone crusher, its application,

获取价格

2023/2/28 Short head cone crushers have a shorter mantle and bowl liner, which allows them to be used for finer crushing applications. They also have a smaller feed opening, which can result in a smaller product size. ... How does a cone crusher work? A: Cone crushers use a mantle and a bowl liner to crush materials. The mantle moves in

获取价格

Gyradisk Cone Crusher. For finer size products (e.g., -6 mm), a special cone crusher known as the Gyradisc is commonly used. Operation is similar to the Standard Cone Head; however, breakage is mostly by attrition rather than impact. Reduction ratio is around 8:1. Feed size is limited to less than 50 mm with a nip angle between 25 ° and 30 °.

获取价格

HP cone crusher cavity selection Standard Short head Crusher size Cavity Minimum setting “A“ Feed opening “B“ Minimum setting “A“ Feed opening “B“ HP100 Extra fine Fine Medium Coarse Extra coarse 6 mm (0.24 in) 9 mm (0.35 in) 9 mm (0.35 in) 13 mm (0.51 in) 21 mm (0.83 in) 20 mm (0.79 in) 50 mm (1.97 in) 70 mm (2.76 in) 100 mm (3 ...

获取价格

Short-head cone crusher has a steeper head angle, a longer parallel section between cone and bowl, and a narrower feed opening. They deliver a crushed product ranging from 1/8″ up to ¾”, and usually work in closed circuit. The clearance between cone and bowl helps the ore to spread as it works its way down.

获取价格

the HP short head cavity it is 2-4. Wear parts application guide - HP series cone crusher HP cone crusher and basic concepts Product Feed Reduction ratio = F80 / P80 The HP cone crusher is a compressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock

获取价格

2023/2/7 The standard cone crusher has a large head angle, coarser discharge, and higher capacity, while the shorthead cone crusher has a steeper head angle, finer discharge and higher fines production.

获取价格

for Symons® short head cone crusher We have designed a main shaft extension conversion component for short head crushers to make liner replacement faster, easier and safer. Our main shaft extension comes with a torch ring that is located above the backing cavity and manganese mantle. The conventional main shaft design requires

获取价格

Short-head cone crusher has a steeper head angle, a longer parallel section between cone and bowl, and a narrower feed opening. They deliver a crushed product ranging from 1/8″ up to ¾”, and usually work in closed

获取价格

the HP short head cavity it is 2-4. Wear parts application guide - HP series cone crusher HP cone crusher and basic concepts Product Feed Reduction ratio = F80 / P80 The HP cone crusher is a compressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock

获取价格

2023/2/7 The standard cone crusher has a large head angle, coarser discharge, and higher capacity, while the shorthead cone crusher has a steeper head angle, finer discharge and higher fines production.

获取价格

for Symons® short head cone crusher We have designed a main shaft extension conversion component for short head crushers to make liner replacement faster, easier and safer. Our main shaft extension comes with a torch ring that is located above the backing cavity and manganese mantle. The conventional main shaft design requires

获取价格

2024/3/5 Browse a wide selection of new and used SYMONS Crusher Aggregate Equipment for sale near you at MachineryTrader. Top models include 3 FT STD, 4.25 FT, 3 FT SH, and 4.25

获取价格

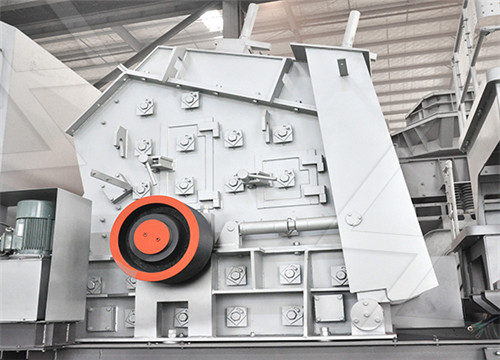

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

获取价格

Kenmore Group of companies offer a wide range of liners and spares for most common cone crushers ranging from 2′ , 3′, 4′, 4 1/4′, 5 1/2′ and 7′ as well as an engineering service to design and supply liners or spares for your specific crusher needs. ... Our engineers are always working to improve liner life and it is this hard work ...

获取价格

2023/2/28 How Gyratory Cone Crushers Work. A gyratory cone crusher consists of a mantle and a concave surface, which are both lined with wear-resistant materials. The mantle gyrates within the concave, creating a crushing chamber that reduces the feed material to the desired size. ... The two most common types are standard and short

获取价格

2021/4/12 Short-head Cone Crushers work exactly like Standard Cone Crushers, but they feature a smaller crushing cavity, making them ideal for finer crushing applications. The closed-side setting on a Short-head Cone Crusher can be adjusted tighter than a standard cone to improve final product size and shape. Short-head Cone Crushers

获取价格

Jaw, Cone and Gyratory Crushers. In some cases, the Run of Mine (ROM) ore from the mine can be fed to a cone crusher via conveyors and screens, but more often, the feed material will come from upstream primary crusher(s) and cone crushers will be used for downstream crushing stages. Purpose of Crushers

获取价格

Size: 4 ¼ Ft. Short Head (1973) Manual Adjust Condition: Reconditioned Manufacture: Symons Includes: Crusher Sheave Lube Tank /Hoses Unit was completely disassembled and inspected The.....

获取价格

works especially well in HP cone crushers, because of their unique crushing kinematics and general chamber profile shapes. Metso XT720 alloy gets you more with less ... • Short head fine 0-16 mm • Short head medium 0-16 mm • Short head coarse 11-22 mm • Standard fine 11-22 mm

获取价格

5.1.1 Cone crushers Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties. Two variations are available - standard and short head The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher.

获取价格

2023/8/7 The MCC Series Cone Crusher by Minyu is used for standard or coarse crushing and can be stationary or portable. Skip to content. Menu. Crushing. Cone Crushers; Jaw Crushers; Impact Crushers; ... 40 / Short Head: 3in / 80mm: 5/16in / 8mm: 630: 120-150 / 90-110: 23,122 / 10,510: MCSS1000: 40 / Ultra-Fine Shorthead: 2in /

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين