5 Figure 3: Granular flow regimes and the Froude number associated with each bed movement [13] Yin et al. [14] stated that the flow into the active layer depends mainly on

获取价格

The ROTARY KILN HANDBOOK OPERATION SIZING DESIGN CONSIDERATIONS MAINTENANCE a product of Contents INTRO About FEECO 1 Intro to Rotary Kilns 3

获取价格

2023/2/25 Introduction. The rotary kiln is used in many solid processes, including drying, incineration, heating, cooling, humidification, calcination and reduction. This

获取价格

The rotary kiln was invented in 1873 by Frederick Ransome. He filed several patents in 1885-1887, but his experiments with the idea were not a commercial success. Nevertheless, his designs provided the basis for successful kilns in the US from 1891, subsequently emulated worldwide. This is made from rolled mild steel plate, usually between 15 and 30 mm (½" t

获取价格

Introduction. Rotary kilns (Figure 1) are used for a range of mineral processing operations. Kilns range in size from 2–6 m in diameter and can be 50–225 m long with an operating

获取价格

Due to the large delay, strong nonlinearity and coupling among variables of the rotary kiln production process, we select the roasting material temperature, oxygen content and kiln

获取价格

Kilns range in size from 2–6 m in diameter and can be 50–225 m long with an operating mass of up to 3000 t. Two of the most common applications are cement production and

获取价格

2017/3/1 The developed model was simulated using finite difference technique. They carried out a parametric study related to better design of rotary kiln, which required

获取价格

2014/11/1 for simulation calculation. Combined with the specific structure in practical rotary kiln, the following several factors of the modeling are determined:9 1. The choice

获取价格

When coal is used as fuel, the ash content and its composition should be considered in raw mix design. LSF of clinker lies in the range of 92-98. Higher LSF at controlled free lime content translates to better quality of

获取价格

2019/6/3 The rotary cement kiln forms a major part of any cement works. The kiln is a large cylindrical structure where the raw materials are brought together and heated to form clinker, the base material of cement.

获取价格

2017/2/14 The metallic iron in this process is produced by the reduction of iron oxide below the fusion temperature of iron ore (1535 deg C) by utilizing carbonaceous material present in the non-coking coal. As

获取价格

laterite, iron ore reduction, and spodumene (lithium) production. In this paper the direct reduction of iron ore to sponge iron is used as an example. The model incorporates a large number of variables covering, amongst others: feed properties and rates, combustion options, kiln operating information (speed and fill level),

获取价格

2023/2/25 In 1872, Johnson came up with the idea of combining the cooking and prior drying of the mixture in an oven, which he called the “chamber kiln or Johnson's kiln” [3]. In 1877, the shaft kiln (a vertical flowing kiln) was invented. This design offered a modification of previous kilns: material and fuel were fed into the kiln from above.

获取价格

The early commercially successful rotary kilns in Britain were nearly all "straight" cylinders, the exceptions being those at Norman (1904). Lengthening of the early kilns at Wouldham and Bevans resulted in kilns with enlarged burning zones, while the lengthened kilns at Swanscombe had enlargements at both ends. Among new installations from 1909 to

获取价格

Refractory is a critical component in the design of a direct-fired rotary kiln, helping to protect the kiln shell from the harsh processing environment within and promote process efficiency. A customizable part of kiln design, refractory can be engineered to suit the unique needs of an application, with factors such as material and multiple ...

获取价格

2020/7/3 In this paper, according to the type and scale of hazardous waste incineration, process selection, design of rotary kiln incinerator, and the engineering principle and performance characteristics ...

获取价格

Posts Related to design calculation of rotary dri kiln. Online Service. Get Price; rotary calciner design calculations mnque-recruitment. rotary dryer calculation spreadsheet Mining. Apr 07, 2013 rotary dryer calculation spreadsheet, Rotary Dryers Coolers and Calciners, rotary dryer design calculations design calculation of rotary dri kiln, .

获取价格

RAW MATERIALS. The basic ingredients for portland cement consist of limestone, sea shells, marl, or chalk, that provide the calcareous components; clay, shale, slate, or sand, to provide the silica and alumina; and iron ore, mill scale, or

获取价格

Due to its high degree of mechanization and low labor intensity, many sponge iron plants around the world use the rotary kiln process to produce sponge iron. This time we introduce a new design sponge iron rotary kiln energy comprehensive utilization system, no matter from the sponge iron kiln design, or the improvement of production links ...

获取价格

Download scientific diagram Schematic presentation of vertical shaft kiln; (a) preheating zone, (b) reacting zone, and (c) cooling zone from publication: Energy optimisation of vertical shaft ...

获取价格

2011/10/29 To calculate we need three values-Volts: We know we put 230v in the system - Resistance:. calculate this for each element separate . We use here two of the exact same length so resistance is the same. To calculate surface load you need surface area. Here: 288,4cm² per element used. 5.1 Serial connection:

获取价格

2015/2/28 The objective of this work is to compare turbulence models when modeling the kiln aerodynamics of an iron ore pelletizing rotary kiln. ... T.J., Jesperson, D.: The design and application of upwind schemes on unstructured meshes. AIAA Paper 89–0366 (1989) ... Lundström, T.S. Marjavaara, B.D. Calculation of Kiln Aerodynamics with two

获取价格

Due to its high degree of mechanization and low labor intensity, many sponge iron plants around the world use the rotary kiln process to produce sponge iron. This time we introduce a new design sponge iron rotary

获取价格

Download scientific diagram Schematic presentation of vertical shaft kiln; (a) preheating zone, (b) reacting zone, and (c) cooling zone from publication: Energy optimisation of vertical shaft ...

获取价格

2011/10/29 To calculate we need three values-Volts: We know we put 230v in the system - Resistance:. calculate this for each element separate . We use here two of the exact same length so resistance is the

获取价格

2015/2/28 The objective of this work is to compare turbulence models when modeling the kiln aerodynamics of an iron ore pelletizing rotary kiln. ... T.J., Jesperson, D.: The design and application of upwind schemes on unstructured meshes. AIAA Paper 89–0366 (1989) ... Lundström, T.S. Marjavaara, B.D. Calculation of Kiln Aerodynamics with two

获取价格

2017/8/1 Integrated iron and steel works operate their own lime kilns in captive plants. These lime kilns are often fired with coke oven gas, converter gas or mixed gas and these gases contain almost no sulphur. ... (FEM) calculations to optimise the design of lime shaft kilns. This is important in order to save material and manufacturing costs.

获取价格

2019/6/4 Innovative System Design And Engineering, ISSN 2222-1727 (paper) ISSN 2222-2871 (online), ... Sponge iron is a type of iron produced by coal based or gas-based reduction of iron ore. It is ...

获取价格

2012/3/29 Grate process is an important step in grate-kiln pellet production. However, as a relatively closed system, the process on grate is inaccessible to direct detection, therefore, it is hard to control. As a result, mathematical models of temperature distribution, moisture distribution and oxidation degree distribution in pellet bed, with good

获取价格

2012/6/1 Highlights Present work deals with two design modifications proposed for sponge iron plant. First design accounts for preheating of kiln air using waste gas exiting from ESP. For second design water is heated using hot sponge iron to preheat rotary kiln air. A model is developed to compute coal demand of process based on different factors.

获取价格

Höganäs Borgestad The Cement Handbook 5 Don’t ignore the tire rings When starting up a cold kiln, it is important to allow time for the tire rings to expand in pace with the kiln

获取价格

2019/12/26 Design elements. The essential design elements of a rotary kiln are shown in Fig 1 and Fig 2. The rotary kiln consists of a lined hollow cylinder, mounted in an inclined position on rolls and rotated slowly by a drive. ... For example, in the kiln used for iron ore reduction, low-iron alumina or magnesium – spinel bricks are used, while in a ...

获取价格

2022/10/26 A rotary kiln is a unique facility with widespread applications not only in the process industry, such as building-material production, but also in the energy sector. There is a lack of a more comprehensive review of this facility and its perspectives in the literature. This paper gives a semi-systematic review of current research. Main trends

获取价格

2020/5/1 The fabricated charcoal fish smoking kiln was done to improve on the performance of the existing technology and determine its performance for future applications.

获取价格

Evaporation ratio of kiln volatile cycle. K, Na, S Cl are all subject to partial evaporation at kiln burning zone temperatures. Volatization in burning zone and condensation in preheater may be represented as shown below.

获取价格

2022/5/5 This paper summarizes more than a decade of systematic studies of the flow field in an iron ore pelletizing rotary kiln using computational fluid dynamics (CFD) on simplified models of a real kiln. Physical, laser-based experiments have been performed to validate part of the numerical results. The objective is a better understanding of the kiln

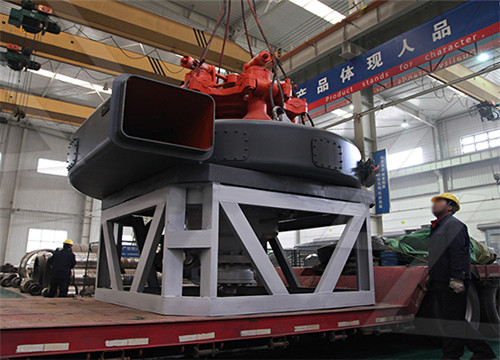

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين