2021/8/13 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry,

获取价格

As a novelty, a calculation procedure for the crushing power of crushers is proposed where the torque is computed with radial forces because only these forces are transmitted to the eccentric. 2. Gyratory Crusher A

获取价格

2020/10/1 1. Introduction. The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet

获取价格

CRUSHING. 2. GYRATORY CRUSHERS. The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo

获取价格

The gyratory crusher is a crushing device used for the coarse crushing of large ore and rock blocks, and its operational mechanism is illustrated in Fig. 2 (a). When the gyratory

获取价格

2023/11/1 Shortly after the start-up of the loaded gyratory crusher, a severe failure issue occurred in the eccentric bushing of the crusher. Based on the analysis of working

获取价格

The majority of gyratory crushers are used as primaries, i.e. they receive the initial feed from the mine or quarry. The same type of crusher with chamber modifications is used

获取价格

2021/8/13 calculation procedure for the crushing power of crushers is proposed where the torque is computed with radial forces because only these forces are

获取价格

2021/2/1 To optimize the crushing chamber of the gyratory crusher, the discrete element method (DEM) is used to explore the influence of the concave curve height,

获取价格

In this training module, Performance Associates International (PAI) covers the characteristics of a gyratory crusher that’s designed to be the first stage in the size reduction of run-of-mine ore. A gyratory crusher

获取价格

2021/8/13 Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant

获取价格

Torque Limiter Yes "Start under load" capability Yes CG810i CG820i CG830i CG850i Standard eccentric throw, mm 29 32 33 35 ... 6 SANDVIK CG800 i GYRATORY CRUSHER SERIES CG810i CG820i CG830i CG850i Piston Material Cast Steel Diameter, inner, mm 350 140 140 140 Diameter, outer, mm 600 690 955 1,000

获取价格

2023/11/1 Shortly after the start-up of the loaded gyratory crusher, a severe failure issue occurred in the eccentric bushing of the crusher. Based on the analysis of working conditions and force, the failure mechanism of the eccentric bushing is studied in detail by combining macroscopic analysis, finite element analysis, scanning electron microscopy

获取价格

The design of our gyratory crushers and jaw gyratory crushers is based on over one hundred years of experience gained by thyssenkrupp in the manufacture of these machines. Changing mining and processing techniques demand, besides new materials and design methods, continuous development of the products.

获取价格

All the benefits of a gyratory crusher – with the largest feed opening . The Jaw Gyratory Crusher Pro is engineered to handle bigger chunks of material than comparable gyratory crushers of the same mantle diameter. This gives you greater flexibility in your crushing operation, and reduces the tendency for bridging in the feed zone.

获取价格

As a novelty, a calculation procedure for the crushing power of crushers is proposed where the torque is computed with radial forces because only these forces are transmitted to the eccentric. 2. Gyratory Crusher A gyratory crusher consists of a movable and truncated conical head and a fixed concave shell, as is presented in Figure 1.

获取价格

2016/1/17 The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under choke-feed or regulated feed conditions. It is possible, when all conditions are favourable, to

获取价格

Gyratory crushers are the heart of your operation and every minute of downtime is costly. You can reduce rebuild time and eliminate hazards with our EZ Nut for Gyratory Crushers. No more ramming and banging to tighten the head nut, or countless hours spent burning the burn rings. ... The EZ Nut uses the Torque Bolt Technology for easy ...

获取价格

IMS Engineering’s range of ETCL/Kawasaki comminution equipment includes primary and secondary gyratory crushers, cone crushers, jaw crushers and specialised ball mills. The crushers are of heavy-duty construction, very robust and proven globally in hard rock applications including granite, basalt, gneiss, greywacke, iron ore and slag.

获取价格

2021/2/1 To optimize the crushing chamber of the gyratory crusher, the discrete element method (DEM) is used to explore the influence of the concave curve height, concave curve radius, eccentric angle, and ...

获取价格

2024/7/29 The gyratory crusher is one of the most important mineral processing assets in the comminution circuit, and its production performance directly impacts the circuit throughput. Due to its higher energy utilisation rate for rock breakage than semi-autogenous (SAG/AG) milling, it is a common practice in operations to promote and optimise primary

获取价格

Stationary gyratory crushers. CG820i Capacity (by hour) 1,500 - 4,000 mtph (1,650 - 4,400 stph) Feed opening 1,372.0 mm (54.0 in.) Motor power 525 kw (700 hp) Sandvik CG820i crusher is built to be robust, reliable and efficient. Connected to SAM by Sandvik, they revolutionize availability and optimize uptime by giving you actionable insights ...

获取价格

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To optimize the design and to ... Torque Analysis of a Gyratory Crusher with the Discrete Element Method ...

获取价格

2020/10/1 1. Introduction. The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]].In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues

获取价格

2024/7/29 The gyratory crusher is one of the most important mineral processing assets in the comminution circuit, and its production performance directly impacts the circuit throughput. Due to its higher energy utilisation rate for rock breakage than semi-autogenous (SAG/AG) milling, it is a common practice in operations to promote and optimise primary

获取价格

Stationary gyratory crushers. CG820i Capacity (by hour) 1,500 - 4,000 mtph (1,650 - 4,400 stph) Feed opening 1,372.0 mm (54.0 in.) Motor power 525 kw (700 hp) Sandvik CG820i crusher is built to be robust, reliable

获取价格

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To optimize the design and to ... Torque Analysis of a Gyratory Crusher with the Discrete Element Method ...

获取价格

2020/10/1 1. Introduction. The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]].In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues

获取价格

2020/4/22 The gyratory crushers will process raw iron ore material at the site, which is being developed to deliver first ore in mid-2022. ... Power Torque; Prime Mover Magazine; Quarry; Roads Online;

获取价格

Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. ... You will find hammer mills being used in industries like agriculture, medical, energy ...

获取价格

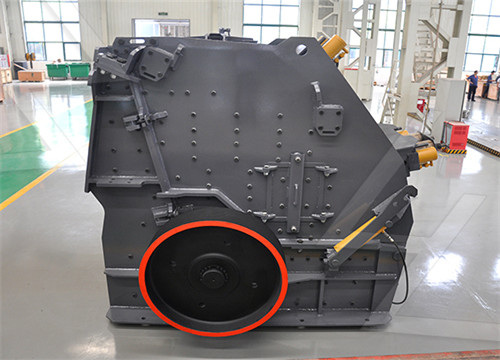

Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by the ...

获取价格

The gyratory crusher has been built in three types known respec- tively as the suspended-spindle, the supported ... as the sup porting member, is the most used. These three types all have some common features, the principal ones being as follows. Referring to Fig. 22. the main frame or top shell (I) supports concaves (2). The mantle (3) is ...

获取价格

2016/2/17 Wearing parts in the gyratory crusher may be either chilled cast iron or manganese steel, depending on the character of the material to be crushed and the particular class of service for which the machine is intended. Standard crushers, in the small and medium sizes, are customarily fitted with chilled-iron head and concaves for

获取价格

2023/10/9 Gyratory crushers serve a pivotal role in mining and aggregate operations, using sheer centrifugal force to efficiently grind rocks and ore. The advanced Metso gyratory cone crusher line, called the Superior MK series, includes the MKIII models that deliver major gains in productivity, uptime, and cost-efficiency over previous models..

获取价格

2015/7/18 The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil system. It is this eccentric bushing and bearing that gives the crusher its crushing action. ... A pinion gear is a small gear driving or being driven by a larger one. In this case the pinion gear is ...

获取价格

The main characteristic of jaw gyratory crushers is their enlarged feed opening, which is located on one side of the crusher only. Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged

获取价格

CG850i Gyratory crushers: 500 (550) 1,549 (61) 3,800-8,250 (4,180 - 9,075) The knowledge hub Over the last 150 years, we've learned a thing or two about crushing and screening. As innovators and experts in the field, we have a deep understanding of technical and mechanical factors, but there’s more to it than that. Find out at our knowledge ...

获取价格

world combine to create a Primary Gyratory crusher with the best performance, highest capacity and highest reliability. Metso Outotec’s line of Superior™ Primary Gyratory crushers are designed to meet the demand for high efficiency and high capacity mining installations. Superior™ MKIII is the first high speed Gyratory. The new

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين