2024/1/16 The paper offers insights into significantly improving the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational unit using a standard screening flowsheet versus the proposed one. 2 Experimental.

获取价格

the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational unit using a standard screening flowsheet versus the proposed one. 2

获取价格

The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant. The particle size distribution resulting

获取价格

2024/4/19 The iron ore screening process plays a pivotal role in determining the dimensions of pellets that enter the firing process of a pelletizing plant.

获取价格

2023/8/1 Much of the remaining iron ore resources in Brazil consist of low-grade itabirite ores. Accordingly, a typical beneficiation circuit includes a four-staged

获取价格

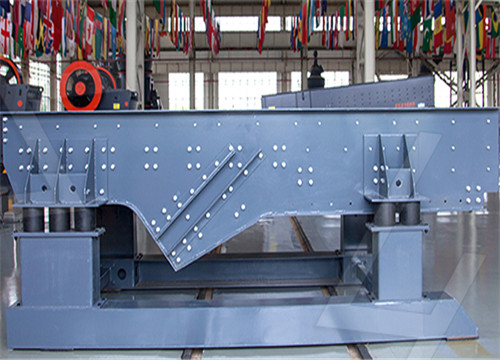

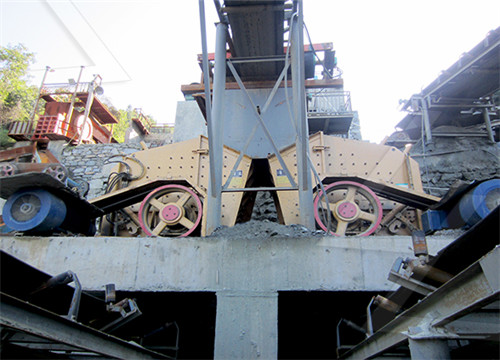

2017/3/3 For example, one of such objects in minerals processing plants is the vibrating screen, Fig. 1. Sieving is a process of separation of the ore material into multiple grades by particle size [1] .

获取价格

iron ore (DSO) projects are using mobile crushing plant based on innovative designs from vendors. The attractions are flexibility, mobility, capital cost savings and the ability to

获取价格

2018/3/1 1. Definition. Screening is the process by which granulated ore material gets separated into different grades of particle size. In other words, it’s a mechanical

获取价格

2022/1/1 Vale, the largest iron ore company in world, is developing its S11D project, located in the Amazon region of northern Brazil (Carajas), which is expected to produce

获取价格

Life cycle assessment of iron ore mining and processing. N. Haque, T. Norgate, in Iron Ore, 2015. 20.2.5 Screening and separations. Screening is an important step for dry beneficiation of iron ore. Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable minerals are ...

获取价格

2024/6/20 Plant growth reduces soil microbial diversity in the iron ore landfill area. • Plant species greatly determine the rhizosphere bacterial community structure. ... The composition and function of plant rhizosphere microbial communities were determined by factors ... Screening of plant growth promotion ability among bacteria isolated from field ...

获取价格

2017/3/3 For example, one of such objects in minerals processing plants is the vibrating screen, Fig. 1. Sieving is a process of separation of the ore material into multiple grades by particle size [1] .

获取价格

2016/6/20 A-Z Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size. Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”. Knowledge of

获取价格

Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media.Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements. Our polyurethane and rubber iron ore

获取价格

Iron Ore Pellets Screening Solutions - Metal 7 - Iron Ore - H6203 horizontal screen - YouTube. Jul 09, 2018 Shougang Peru iron ore new district expansion project is located near the east coast of the Marcona area in Peru.

获取价格

2018/7/11 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

获取价格

2021/3/15 ABSTRACT. The behavior of iron ore pellet binders is complex. Any pellet binder is subject to a handful of practical requirements: that it be readily dispersed through a pellet, that it effectively controls the movement of water within the pellet, and that it contributes to the inter-particle bonding within the pellet.

获取价格

The iron ore lump obtained from ROM crushing and screening plants will continue to break down into − 6.3 mm particles during material handling from the product screen to stockpiles, port, and customer.Drop test conditioning of diamond drill core and crusher lump samples has been developed to simulate material handling and plant stockpiling ...

获取价格

The iron ore wash plant also removes clays from the feed material and the combined effect means the Fe content increases from between 43.4% and 52.7% in the feed to above 60% iron ore product, with a yield of up to 50%. ... The plant consists of an initial washing and screening stage using CDE’s M-Series™ modular range equipment followed by ...

获取价格

2021/12/2 Iron Ore: Mineralogy, Processing and Environmental Sustainability, Second Edition covers all aspects surrounding the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world's largest trillion-dollar-a-year metal market and is the backbone of the global infrastructure. The

获取价格

depend on each ironmaking furnace and thoserequirements influence the operation ofthe iron ore pelletizing plant. The idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first ... The balling disc worksin close circuit with the screening step, where pellets smaller than 8 mm or larger than 16 mm are ...

获取价格

Spiral Separators for heavy minerals. Our gravity separators for heavy mineral applications, including iron ore, chrome, mineral sands and other high density minerals, separate particles in the size range 2 to 0.04 mm.. We have a range of spirals, from 3 to 12 turns, with high-, medium- and low-gradient profiles.

获取价格

Good geotechnical information is essential to crushing plant siting and design. Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel. Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant. Short-term mine lives

获取价格

2021/12/2 Iron Ore: Mineralogy, Processing and Environmental Sustainability, Second Edition covers all aspects surrounding the second most important commodity behind oil. As an essential input for the production of crude steel, iron ore feeds the world's largest trillion-dollar-a-year metal market and is the backbone of the global infrastructure. The

获取价格

depend on each ironmaking furnace and thoserequirements influence the operation ofthe iron ore pelletizing plant. The idea of rolling moist fine ore in a drum to form balls and then drying and firing it was first ... The balling disc worksin close circuit with the screening step, where pellets smaller than 8 mm or larger than 16 mm are ...

获取价格

Spiral Separators for heavy minerals. Our gravity separators for heavy mineral applications, including iron ore, chrome, mineral sands and other high density minerals, separate particles in the size range 2 to 0.04 mm..

获取价格

Good geotechnical information is essential to crushing plant siting and design. Installing a primary crushing plant on solid rock reduces the cost of concrete and structural steel. Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant. Short-term mine lives

获取价格

2024/2/8 Present investigation includes the magnetizing roasting of low-grade iron ore fines followed by grinding and beneficiation using magnetic separation. The hematite iron ore used in the investigation contains 53.17% T Fe, 10.7% SiO2, and 4.5% Al2O3. Powdered bituminous coal of 210 μm size with an ash content of 12.5% and fixed carbon

获取价格

simple, comprising crushing and dry screening with no tailings/wastes. Off grade material is concentrated ... Joda East Iron Mine (JEIM) is one of the major captive sources of iron ore to the Tata Steel plant at Jamshedpur and supplies approximately 45% of work’s total iron ore requirement. The mine produces iron ore fines (0.15–10 mm) and ...

获取价格

2015/3/15 Understanding Sinter and Sinter Plant Operations. satyendra; March 15, 2015; 8 Comments ; fluxes, Iron ore fines, SCFA, sinter, sinter plant. basic sinter, sintering machine,; Understanding Sinter and Sinter Plant Operations Sintering is a process of agglomeration of fine mineral particles into a porous and lumpy mass by

获取价格

sponge iron process. Jul 29, 2010 As the manufacture of sponge iron is very sensitive to the physical and chemical characteristics of raw materials, a well designed raw material preparation plant with crushing/screening facility for iron ore and coal to control the size of input materials to the kiln is a .

获取价格

2022/1/1 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021).As shown in Fig. 1.3, China is the largest iron ore

获取价格

2013/3/9 Important issues related to sinter and sinter plants. The following are the important issues related to sinter and sinter plants. Use of sinter reduces the coke rate and enhances the productivity in blast furnace. Sintering process helps utilization of iron ore fines (0-10 mm) generated during iron ore mining operations.

获取价格

2024/6/20 The sand iron ore restoration area in Qinghe County belongs to a typical continental northern temperate arid climate, mainly composed of. Conclusion. The soil and climate in the sand iron ore landfill area of Qinghe County are special, whereas its microbial diversity remains high, and the undiscovered strains are relatively abundant.

获取价格

2024/1/16 The paper offers insights into significantly improving the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational unit using a standard screening flowsheet versus the proposed one. 2 Experimental. Simulations using the discrete element method (DEM) were conducted using an open

获取价格

2024/3/6 The extracted ore is then crushed and screened to remove impurities before being transported to a processing plant. Depending on the type of iron ore and its quality, different extraction methods such as open-pit mining or underground mining may be employed. The efficiency of mining operations directly impacts the availability and cost of

获取价格

2015/7/25 Vibrating Grizzly Screen. A vibrating grizzly screen has been developed as a distinct improvement over the fixed grizzly now in such wide use. It combines the functions of screening and feeding the ore to the primary crusher, and, by eliminating the undersize product in the ore feed to the crusher, materially increases the crusher capacity.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين