In this process, uranium ore is extracted from the Earth’s crust, similar to mining copper, zinc, and other metals. ... A typical reactor may contain about 100 tonnes of ... the in-place ore through an array of regularly

获取价格

Uranium Extraction. Uranium leaching is the process by which the uranium is extracted from the raw ore by reacting the material with acid or base. Fig. 2 shows a general process flow for the uranium extraction process.

获取价格

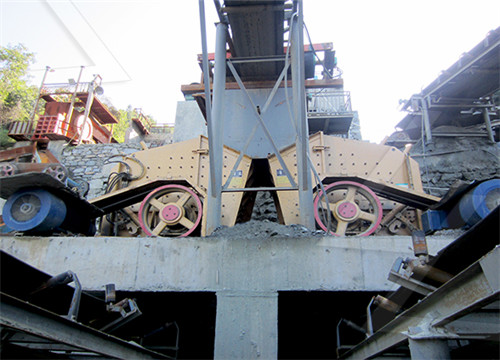

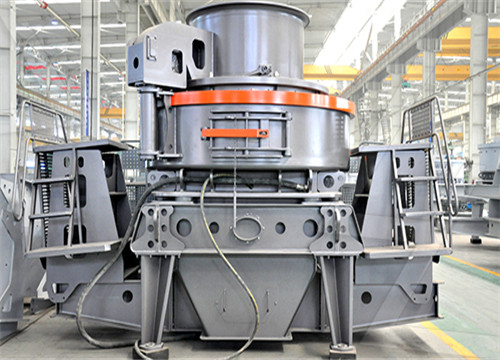

2024/5/16 Conventional mines have a mill where the ore is crushed, ground and then leached with sulfuric acid to dissolve the uranium oxides. At the mill of a conventional

获取价格

Uranium is a naturally occurring radioactive element very widely distributed throughout the earth’s crust [ 1 ]. It is present in varied concentration in almost all types of rocks, natural

获取价格

Overview of Uranium Mining and Processing Canada. Largest uranium producer before 2020, accounting for +20% of world output. Have the highest ore grade in the world.

获取价格

Typical underground uranium mine sites range from 10 to 25 acres. Uranium Ore Milling. After uranium ore is removed from the ground, it must be processed to extract the contained uranium. This process, “milling,”

获取价格

2013/12/31 Processing of the ore to a concentrate occurs at or near the mines. Most of the uranium ore deposits at present supporting today’s mines have average grades in excess of 0.10% of uranium. In the ...

获取价格

A conventional uranium mill is a chemical plant that extracts uranium using the following process: Trucks deliver uranium ore to the mill, where it is crushed into smaller particles

获取价格

The CNSC ensures streams, lakes and rivers downstream of uranium mining projects are safe for people, plants, fish and other animals. Uranium mine and mill licences are issued for an average of five years. Uranium mines and mills are routinely inspected by CNSC and provincial inspectors.

获取价格

2023/10/26 The nuclear fuel cycle consists of two phases: the front end and the back end.Front-end steps prepare uranium for use in nuclear reactors. Back-end steps ensure that used—or spent—but still highly radioactive, nuclear fuel is safely managed, prepared, and disposed of.. Nuclear power plants primarily use a specific type of

获取价格

TABLE 4.3 Typical Uranium Mine and Processing Plant Design Criteria That Might Be Applicable to an Ore Deposit in Virginia. Item. Range or Alternative. Range or Alternative ... Process effluents are internally

获取价格

Get Solution Price Right Now! leave your message here, we'll send you an Email immediately. * *

获取价格

2023/11/30 The 100% owned Rosita CPP, located approximately 60 miles from Corpus Christi, Texas, is a licensed, past-producing In-Situ Recovery (ISR) uranium plant with a capacity of 800,000 pounds of U 3 O 8 per year and the ability to expand capacity within the existing license. Located in the Texas Uranium Belt, the Rosita CPP and

获取价格

2024/3/2 Uranium, a cornerstone for nuclear energy, facilitates a clean and efficient energy conversion. In the era of global clean energy initiatives, uranium resources have emerged as a vital component for achieving sustainability and clean power. To fulfill the escalating demand for clean energy, continual advancements in uranium mining

获取价格

Licensing process. The CNSC's licensing process for uranium mines and mills follows the stages laid out in the Uranium Mines and Mills Regulations, proceeding progressively through site preparation and construction, operating, decommissioning, and abandonment (or release from licensing) phases. Using this lifecycle approach to licensing, the CNSC

获取价格

The Project hosts the historical Honeymoon Uranium Mine, which was Australia's second operating in-situ recovery uranium mine, commencing production in 2011 under previous owner, Uranium One. Operations at Honeymoon were suspended in November 2013 in response to falling uranium prices, with the Project subsequently acquired by Boss

获取价格

Uranium ores are normally processed by grinding the ore materials to uniform particle size and then treating the ore to extract the uranium by chemical leaching. A conventional uranium mill is a chemical plant, usually built near the uranium mine. Uranium milling extracts uranium using the following process: Milling. Trucks deliver uranium ore ...

获取价格

In general, conversion is a process in which the uranium is converted to a form suitable either for fuel fabrication or enrichment. A minority of nuclear power plants do not require enriched uranium and for these power plants, the yellow cake (U 3 O 8) is converted to uranium dioxide (UO 2) at the conversion plant.

获取价格

Uranium leaching is the process by which the uranium is extracted from the raw ore by reacting the material with acid or base. Fig. 2 shows a general process flow for the uranium extraction process. Prior to the leaching process, the ore is often given preliminary treatments that can include roasting and grinding.

获取价格

2021/7/23 The majority of uranium mined in South Africa comes from the Witwatersrand Basin, the world’s largest natural deposit of gold. Several multinational companies have established uranium-processing facilities at or near gold mines in the area. For example, First Uranium Corp of Canada built a plant at Ezulwini gold mine in the

获取价格

2022/12/9 The Rosita plant will be used to process uranium feed from multiple satellite operations in the South Texas area. The production capacity of the plant is 800,000 pounds of triuranium octoxide (U 3 O 8). However, installing a larger second dryer can increase it to two million pounds U3O8. ... The Butler Ranch project is located in the ...

获取价格

process water. The pilot plant was designed with a process capacity of 2 m3/h and has been in operation 24 hours a day for a period of 6 months. Samples were taken daily for metal analysis. The plant consists of two sections: pre-treatment and uranium ion exchange. Figure 6. Mine Process Water Pilot Plant

获取价格

Uranium leaching is the process by which the uranium is extracted from the raw ore by reacting the material with acid or base. Fig. 2 shows a general process flow for the uranium extraction process. Prior to the

获取价格

2021/7/23 The majority of uranium mined in South Africa comes from the Witwatersrand Basin, the world’s largest natural deposit of gold. Several multinational companies have established uranium-processing facilities

获取价格

2022/12/9 The Rosita plant will be used to process uranium feed from multiple satellite operations in the South Texas area. The production capacity of the plant is 800,000 pounds of triuranium octoxide (U 3 O 8). However, installing a larger second dryer can increase it to two million pounds U3O8. ... The Butler Ranch project is located in the ...

获取价格

process water. The pilot plant was designed with a process capacity of 2 m3/h and has been in operation 24 hours a day for a period of 6 months. Samples were taken daily for metal analysis. The plant consists of two sections: pre-treatment and uranium ion exchange. Figure 6. Mine Process Water Pilot Plant

获取价格

2024/2/23 The recovered uranium will be processed at the fully operational Irigaray Central Processing Plant, which has a current licensed capacity of 2.5 million pounds of U3O8 (triuranium octoxide) per ...

获取价格

2024/5/16 Conventional mines have a mill where the ore is crushed, ground and then leached with sulfuric acid to dissolve the uranium oxides. At the mill of a conventional mine, or the treatment plant of an ISL operation, the uranium then separated by ion exchange before being dried and packed, usually as U 3 O 8.Some mills and ISL operations

获取价格

In situ recovery is one of the two primary extraction methods that are currently used to obtain uranium from underground. ISR facilities recover uranium from low-grade ores where other mining and milling methods may be too expensive or environmentally disruptive. This method uses the following process, as illustrated in the figure to the right:

获取价格

Calculate activities and radioactive decay of the wastes arising from nuclear fuel production and power plant operation: uranium mine waste rock, uranium mill tailings, depleted uranium, and spent fuel. ... Calculate the material balance for downblending of Highly Enriched Uranium (HEU) - the process being used to make weapons-grade uranium ...

获取价格

2023/11/28 Uranium is the primary fuel for nuclear reactors and must be managed properly, in a safe and sustainable manner. Recent annual production of natural uranium world-wide has been between 55,000 and 65,000 tons of uranium metal, similar to the fuel demand. Additionally, thorium is also being investigated as a potential alternate source of

获取价格

In order to understand the pollution characteristics of typical heavy metals in soil around a uranium mining and the ability of local dominant plants to repair contaminated soil, the soil and plants in the downstream area of the mining were sampled and tested.The results show that the soil in the mining area shows a certain degree of U and Cd exceeding the

获取价格

2024/4/18 Centrus Energy opened a plant at the old Portsmouth Gaseous Diffusion Plant last fall. Now, for the first time in years, the site is producing enriched uranium again.

获取价格

An in situ uranium solution mine consists of 1) a system of injection and recovery wells, 2) pipelines to t ransport barren leach solution (lixiviant) to the injection wells and pregnant, uranium-bearing liquor (leachate) from the• recovery wells, and 3) a process plant where urani urn is extracted from the

获取价格

2023/10/11 The process of pre-conditioning cleans the unwanted chlorides and calcium from the orebody for efficient leaching and uranium capture. Calcium and chloride containing groundwater is pumped from the orebody via extraction wells and processed through the water treatment plant to remove calcium.

获取价格

A conventional uranium mill is a chemical plant that extracts uranium using the following process: Trucks deliver uranium ore to the mill, where it is crushed into smaller particles before being extracted (or leached). In most cases, sulfuric acid is the leaching agent, but alkaline solutions can also be used to leach the uranium from the ore.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين