2024/2/20 Steel slag is a kind of bulk alkaline industrial solid waste produced in the steelmaking process. Resource utilization of this solid waste is an urgent problem to be

获取价格

2022/1/19 1.1. Supplementary Cementitious Materials. The cement industry accounts for about 5–9% of global CO 2 emissions [1,2].Therefore, reducing CO 2 emissions by decreasing cement use via the utilization of supplementary cementitious materials (SCMs) has become an important research field in the building materials industry in recent years.

获取价格

2014/10/15 Accelerated carbonation of alkaline wastes such as steelmaking slag offers the potential to combine waste valorisation with climate change mitigation by utilising carbon dioxide (CO 2).One method of achieving this is through an indirect carbonation process to produce a marketable precipitated calcium carbonate (PCC), using

获取价格

2014/1/1 Carbon dioxide for PCC manufacturing is in general taken from cleaned flue gases of industries located nearby the PCC plant, thus reducing the CO 2 emissions from this specific source. However, the production of reactive calcium from limestone usually generates an amount of CO 2 equal to or larger than what is chemically stored in

获取价格

2023/8/1 Table 2 shows the mix proportions of nine different Na 2 CO 3-activated slag mortars.The sample numbers for the mixtures are also shown in Table 2, where X in C-X represents the percentage of GBFS replaced by CaO, and X in C-GX represents the percentage of GBFS replaced by GP.In the preparation process, the slag, waste GP,

获取价格

2023/8/1 Cement manufacturing consumes large quantities of natural resources, emits considerable amounts of greenhouse gases, and brings harm to the environment.Alkali-activated cementation materials are promising candidates to replace ordinary Portland cement.However, Na 2 CO 3-activated slag mortars suffer from long

获取价格

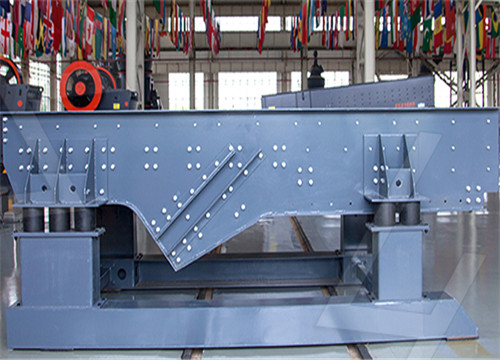

Mobile Impact Crusher Stable, Flexible, Efficient, Functional Mobile Impact Crusher can process mediu... More Mobile Primary Jaw Crusher...

获取价格

2014/12/1 The chemical reactions of the Slag2PCC technology are listed as Eqs. (4), (5), (6).In Eq. (4) CaO represents all ammonium salt soluble calcium regardless of the actual crystal form in which it is bound. The salt can be chloride, nitrate or acetate (Mattila et al., 2012), represented by X in the equations.Schematic process descriptions of the

获取价格

2022/3/1 The production of polyvinyl chloride by calcium carbide method is a typical chemical process with high coal consumption, leading to massive flue gas and carbide slag emissions. Currently, the carbide slag with high CaO content is usually stacked in residue field, easily draining away with the rain and corroding the soil.

获取价格

2024/7/1 1.Introduction. Carbide slag is the by-product of industrial preparation of the acetylene gas, whose main component is calcium hydroxide (Liu et al., 2020; Philbert et al., 2021).To produce 1 ton of acetylene gas, 1.2–1.8 tons of carbide slag are produced (Altiner, 2019).China is the largest calcium carbide manufacturing country in the world, and its

获取价格

2024/5/17 Organic waste salt is a high salt hazardous waste produced by the industrial processes. Presently, there is no viable method to reclaiming and treating this issue. Using the commercial pyrocatechol monois-propyl waste salt from the manufactured pyrocatechol monois-propyl ether, a process was developed for the synergistic

获取价格

2017/12/8 Both steelmaking via an electric arc furnace and manufacturing of portland cement are energy-intensive and resource-exploiting processes, with great amounts of carbon dioxide (CO2) emission and ...

获取价格

2021/9/21 This study provides an overview of calcium rich industrial wastes usage in construction materials, their properties and different applications through marble waste and flue gas desulfurization (FGD) gypsum. Large quantities of industrial wastes are stockpiled and haphazardly disposed in increasing amounts causing serious environmental

获取价格

China is the largest producer and consumer of calcium carbide in the world. The calcium carbide industry is an indispensable industry to support the basic life of people. The huge production capacity of calcium carbide is accompanied by a large number of solid waste carbide slag. Due to the immature treatment technology of carbide slag, a large number

获取价格

2022/5/1 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coal-based CaC 2.CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production. Approximate 40 million tons of dry CCS are generated annually in China,

获取价格

2017/12/8 Both steelmaking via an electric arc furnace and manufacturing of portland cement are energy-intensive and resource-exploiting processes, with great amounts of carbon dioxide (CO2)

获取价格

2021/9/21 This study provides an overview of calcium rich industrial wastes usage in construction materials, their properties and different applications through marble waste and flue gas desulfurization (FGD) gypsum. Large quantities of industrial wastes are stockpiled and haphazardly disposed in increasing amounts causing serious environmental

获取价格

China is the largest producer and consumer of calcium carbide in the world. The calcium carbide industry is an indispensable industry to support the basic life of people. The huge production capacity of calcium carbide is accompanied by a large number of solid waste carbide slag. Due to the immature treatment technology of carbide slag, a large number

获取价格

2022/5/1 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coal-based CaC 2.CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production. Approximate 40 million tons of dry CCS are generated annually in China,

获取价格

Calcium chloride is an inorganic compound, a salt with the chemical formula CaCl 2.It is a white crystalline solid at room temperature, and it is highly soluble in water. It can be created by neutralising hydrochloric acid with calcium hydroxide.. Calcium chloride is commonly encountered as a hydrated solid with generic formula CaCl 2 nH 2 O, where n = 0, 1, 2,

获取价格

2024/2/1 The authors declare that there are no conflicts of interests regarding the publication of the article titled “Hydration mechanism of calcium chloride modified coal gasification slag-based backfill materials”. Acknowledgments. This research was supported by the National Natural Science Foundation of China (Nos. 52222404, 52074212,

获取价格

2023/8/15 The distillation waste stream from the ammonia-alkali process contains 90–120 g/L of calcium chloride. Using calcium chloride as raw material to mineralize carbon dioxide can achieve efficient utilization of calcium chloride waste and CO 2 emission reduction. This article is based on a two-step synthesis method, using

获取价格

Blast furnace slag (BFS), a high volume byproduct resulting from the iron manufacturing industry, was used as a low-cost and abundant precursor for preparing a high-surface-area calcium silicate hydrate. The synthesis of slag-made calcium silicate hydrate (slagCS) was achieved via a facile two-step dissoluti

获取价格

2023/6/12 In Finland, the calcium chloride manufacturing process is performed by TETRA Chemicals Europe at a unique facility in the Kokkola Industrial Park (KIP), a landmark installation known as the “largest ecosystem of inorganic chemical industry” in Northern Europe. [1] ... which are then used and eventually disposed of as waste and

获取价格

Calcium Chloride Manufacturing Processes; Solvay Process. Chemical Process of high purity limestone and salt brine to produce soda ash and Calcium Chloride; ... Calcium Chloride can be produced as a bi-product or waste of a chemical process; Contact us at (706) 860-1893 ...

获取价格

2016/2/21 The concept uses steelmaking slag as raw material and has potential to fix CO 2 emissions and utilize steelmaking slag, simultaneously. As calcium carbonate is precipitated in a solution containing ammonium chloride, calcium chloride, and ammonia, the product needs to be washed and hence filtered.

获取价格

2024/7/1 Based on the composition characteristics of carbide slag and the application of polyvinyl chloride, a method of preparing calcium carbonate with microstructure and nanostructure by using carbide slag as a raw material and ammonium chloride as a leaching agent was proposed. The factors for the preparation of calcium carbonate and

获取价格

2024/2/1 The authors declare that there are no conflicts of interests regarding the publication of the article titled “Hydration mechanism of calcium chloride modified coal gasification slag-based backfill materials”. Acknowledgments. This research was supported by the National Natural Science Foundation of China (Nos. 52222404, 52074212,

获取价格

2023/3/20 Waste recycling and reuse is an important component of sustainability. Extensive research is being conducted to address this issue by incorporating industrial by-product such as steel slag, copper slag, fly ash, ferro-chrome slag, and so on into the construction industry. Steel slag, which is mostly calcium carbonate, is created as a by

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين