Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (3000-4000 Blain) cement. Grinding operation

获取价格

2023/7/19 Grinding aids, primarily amine group chemicals, are used to reduce agglomeration and increase concrete strength in order to ensure an efficient

获取价格

2017/5/19 Abstract. Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of weeks ...

获取价格

2023/10/19 Here’s an exploration of the role of clinker grinding in the cement manufacturing process: ... They are used less frequently than other grinding equipment

获取价格

2015/12/1 The cement industry's share in these emissions may have been overestimated since it does not correspond to the industry's experiences and it has

获取价格

2016/10/5 1. Introduction. Cement is an energy-intensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost [].The

获取价格

2015/4/1 In the process thermal energy is used mainly during the burning, while maximum share of electrical energy is used for cement grinding [3]. ... Fig. 3 represents a schematic diagram of process involving in cement industry while using tyre as alternative fuel [49]. The diagram indicates the saving of coal and iron minerals as input materials.

获取价格

2016/10/5 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over

获取价格

2016/10/22 The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. ... Only close economic study can determine which process should be used. CLINKER GRINDING. Clinker, the discharge product from the kiln, is partially cooled and

获取价格

2023/8/21 How do you control the fineness of the cement during the grinding process? ... The cement industry was expected to add 21.2 million tonnes per annum (mtpa) of manufacturing capacity in the year 2022-23. During the period, projects worth US$ 71.8 billion were expected to get commissioned. This would have been the fourth

获取价格

2017/5/19 Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of weeks. i ...

获取价格

A 10 MW cement mill, output 270 tonnes per hour. A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

获取价格

Some manufacturers grind the raw materials dry, while others use a wet-grinding process involving water. Quarrying. Cement manufacturers quarry raw materials including limestone, clay, and sand. ... The cement and concrete industry is dedicated to reaching carbon neutrality by 2050 or sooner. The use of lower-carbon cement blends, alternative ...

获取价格

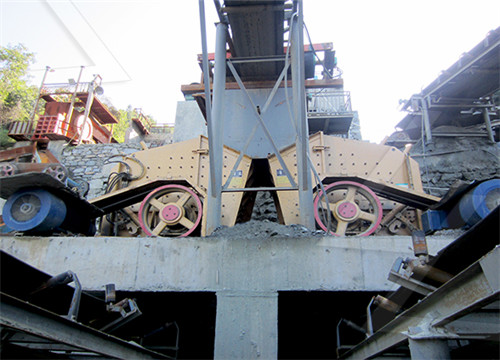

In the cement industry, which uses chiefly medium-hard to hard limestone as its principal raw materials, single-stage crushing plants equipped with hammer crushers are the commonly preferred type. ... The maximum grain size of the material fed into the grinding installation is fixed depending on the process selected for the grinding ...

获取价格

2022/8/10 ICR gets Vimal Jain, Director – Technical, HeidelbergCement India, to share his views about the innovations in technology of the grinding process and grinding aids as well as his understanding on how the entire process can be made more energy-efficient and cost-effective.. Explain the grinding process in cement manufacturing.

获取价格

The grinding process can be done in ball or tube mill or even both. Then the slurry is led into collecting basin where composition can be adjusted. The slurry contains around 38-40% water that is stored in storage tanks and kept ready for the rotary kiln. Fig: Manufacture of Cement by Wet Process

获取价格

The process of cement grinding station can be divided into three types: open-circuit grinding system, closed-circuit grinding system, and combined grinding system. ... industries and do not meet the goals of energy conservation and consumption reduction in the development of modern industry. Cement grinding unit is a key link in cement plant ...

获取价格

Dust emissions are one of the most significant impacts of cement manufacturing and associated with handling and storage of raw materials (including crushing and grinding of raw materials), solid fuels, transportation of materials (e.g. by trucks or conveyor belts), kiln systems, clinker coolers, and mills, including clinker and limestone burning and

获取价格

2023/9/6 Cylpebs: Cylpebs are slightly tapered cylindrical grinding media with rounded edges. They are commonly used in cement and mining industries for finer grinding in ball mills and other grinding equipment. Glass Beads: Glass beads are used in grinding and dispersing applications for materials like pigments, dyes, and coatings.

获取价格

The grinding process can be done in ball or tube mill or even both. Then the slurry is led into collecting basin where composition can be adjusted. The slurry contains around 38-40% water that is stored in storage tanks

获取价格

The process of cement grinding station can be divided into three types: open-circuit grinding system, closed-circuit grinding system, and combined grinding system. ... industries and do not meet the goals of energy

获取价格

Dust emissions are one of the most significant impacts of cement manufacturing and associated with handling and storage of raw materials (including crushing and grinding of raw materials), solid fuels,

获取价格

2023/9/6 Cylpebs: Cylpebs are slightly tapered cylindrical grinding media with rounded edges. They are commonly used in cement and mining industries for finer grinding in ball mills and other grinding equipment. Glass Beads: Glass beads are used in grinding and dispersing applications for materials like pigments, dyes, and coatings.

获取价格

PPC is produced by the inter-grinding and blending of 65% clinker with 30% fly ash and 5% gypsum to a fineness of 320 m 2 /kg. Fineness is a controlled parameter for cement to ensure better hydration and strength development. Ground cement is then stored in a water-proof concrete silo for packing. More ++

获取价格

2013/3/1 Processes like grinding, transport of materials and crushing utilize machine drives and account for the majority of electricity consumption, as is evident in the result of the Manufacturing Energy Consumption Survey (MECS) in 1998 presented in Fig. 3.Process heating, by which clinker is made in large kilns, accounts for about 90% of the

获取价格

2023/9/21 CO 2 emissions from cement production are estimated to be ~8% of India's total emissions, around the global average. The emissions from each stage of the process are shown in Table 7. As elsewhere, Indian cement producers are becoming increasingly aware of their CO 2 footprints. Many are working towards reducing

获取价格

The course’s first objective is to give an overview of the process chain within the cement industry. All the main processes involved during cement production will be discussed, including the extraction and processing of raw materials, the combustion process, cement grinding, quality control and storage, and cement distribution.

获取价格

2023/8/21 ICR looks at the inner workings of grinding mills in the cement industry to understand the technological advancements that are reshaping the landscape against the foreground of sustainability. Innovations to enhance the grinding processes are aimed at minimising their environmental footprint while increasing efficiency and performance. In

获取价格

2012/8/30 Cement Manufacturing Process Phases. ... Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table. Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller. ... Widely used in highways, utilities, construction and other industries washing, grading, cleaning ...

获取价格

2022/7/1 The distribution of electricity consumption across critical unit operations is as follows: cement grinding (31–44%), clinker production (28–29%), raw material grinding (26%) and fuel grinding [17]. ... This limitation of the calcination process makes the cement industry best suited for calcium looping ...

获取价格

Providing a comprehensive guide to the entire cement production process from raw material extraction to the finished product, the industry’s favourite technical reference book is now fully updated with new material and an extended chapter on alternative fuels. Key sections covering raw materials, burning, grinding and quality control are ...

获取价格

2023/7/19 Grinding aids, primarily amine group chemicals, are used to reduce agglomeration and increase concrete strength in order to ensure an efficient comminution process in the modern cement industry.

获取价格

2012/6/1 The feed material is typically composed of the BFRs and the catalyst, both in powder form. As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين