2024/7/26 Cyanide leaching technology was studied for low-grade oxidized gold ores in Guangxi Province. The gold grade of the raw ores was 1.32 g/t. The gold leaching rate was 90.91% under the optimal conditions for the following conventional leaching

获取价格

2019/5/10 To avoid the formation of volatile hydrogen cyanide HCN, the process takes place in a basic solution (pH 10). Generally, an

获取价格

Abstract. A dilute cyanide solution is an efficient solvent of gold. However, as in any other leaching process, the solvent has to come in contact with the solid gold particle. Hence,

获取价格

2016/6/8 The ball mill, in closed circuit with a classifier, is fed with ore, cyanide, lime, and carbon as charcoal. The classifier overflow is thickened and then agitated. The gold is dissolved by the cyanide

获取价格

There are cyanide simulation models that can calculate this. PROCESS SELECTION ELIMINATION When dealing with processing a copper gold ore there are a number of

获取价格

2006/8/1 Leaching in the grinding circuit is currently practiced in plants that process gold ores with low content of cyanide consuming minerals. The high gold recovery

获取价格

2015/11/1 CIL circuit is a process of continuous leaching of gold from ore to liquid and counter-current adsorption of gold from liquid to carbon particles in a series of tanks.

获取价格

2023/10/5 The CLEVR process, said Mai, is an ideal solution for developing gold projects in jurisdictions that are sensitive to the use of cyanide and for projects faced

获取价格

The process developed by Gekko Systems now makes it possible to obtain a high recovery of gold into dore, maximising the benefit obtained by producing a coarse gravity

获取价格

Gold beneficiation is a process that involves two and a half stages of closed-circuit crushing, followed by two stages of closed-circuit grinding and ... ranging from the rocker or long tom of the California Forty-Niner to modern leaching techniques using cyanide. The cyanide process is very efficient, allowing for the recovery of 95% to 98% of ...

获取价格

2016/7/13 Leaching practice has decreased in recent years with the development of closed-circuit grinding and now is seldom incorporated in new plants. Ores are known which need only to be crushed coarsely to ½ in., and the whole leached. Deposits of ore amenable to coarse crushing, however, are rare.

获取价格

2016/7/13 Leaching practice has decreased in recent years with the development of closed-circuit grinding and now is seldom incorporated in new plants. Ores are known which need only to be crushed coarsely to

获取价格

Exploring the Cyanide Leaching Process. Cyanide leaching is a method that has transformed the gold mining industry with its effectiveness and efficiency. The process involves a chemical reaction between cyanide and the minute particles of gold found within ore, forming a solubilized gold-cyanide solution.

获取价格

2016/4/21 Gold Leaching Circuits Equipment. In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mine.The small mine of today may develop into the large mine of tomorrow. Under proper management and financing it has as good a chance of yielding a profit as the larger property.

获取价格

Gold processing - Mining, Concentrating, Refining: The nature of the ore deposit determines the mining and mineral processing techniques applied. Oxide ore deposits are frequently of such low grade (e.g., 3 to 10 parts per million) that extensive mineral processing cannot economically be justified. In this case they are merely shattered by

获取价格

South Deep’s gold plant has the capacity to process around 330,000 tonnes of ore per month and the capability to treat more underground ore than most other plants in the Far West Rand Region of South Africa. ... South Deep’s milling circuit consists of a single-stage semi-autogenous grinding mill (SAG) and a pebble crusher for primary ...

获取价格

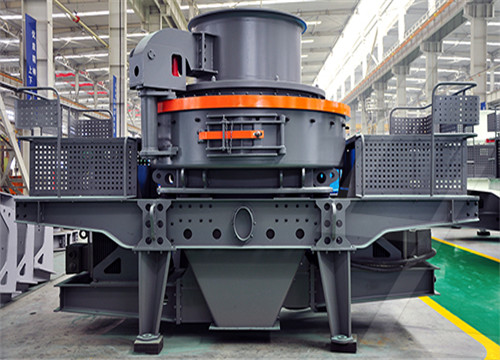

2020/5/8 The crushing and screening stage in the industry is mainly composed of three-stage and a closed-circuit process. Gold ores need to go through coarse, medium, and fine crushing processes to be reduced into smaller pieces. ... 1 Contact finely ground ore with the solution containing cyanide ; 2 Separate solid from the clear solution;

获取价格

There is no feeding from the water wells in the process plant. The facility operates in a closed circuit with the water reused from the tailing dam. During the processing operation, 0.5 kg / hour lime and 0.5 kg / t sodium cyanide are used. The unit water footprint values for sodium cyanide and lime are 0.196 m 3 / kg and 0.02 m 3 / kg ...

获取价格

The oxide ore is milled in the Juniper Mill and conveyed to the CIL circuit for blending with neutralized sulfide ore from the autoclave process. Tailings from the combined sulfide and oxide ore processing are dosed with a Caro’s Acid (or back up hydrogen peroxide) for cyanide destruction before disposal in the Juniper Tailings Storage Facility.

获取价格

2015/2/7 The net result is the complication of the chemistry involved in the cyanide process. Compare Cyanide VS Thiosulphate gold Leaching. No two ores are exactly alike. Therefore, it is practically impossible to predict how an ore will act during cyanidation, although broad generalizations can sometimes be made.

获取价格

2021/12/1 If magnesium inputs into the water circuit can be minimized, the lime-cyanide trade-off consideration mentioned earlier may favour an operational pH > 10.5. ... as well as the tailings and residues rejected from ore processing, often contain minerals that may give rise to well-documented acid generation, so called acid rock drainage or

获取价格

Silver is often associated with lead-zinc ore, copper ore, gold ore, and limonite, and is mainly produced by flotation.The silver intercalation in its silver-bearing minerals is fine and complex in size, and combined beneficiation methods such as flotation-cyanidation and gravity separation-flotation are often used.. JXSC will customize complete silver ore

获取价格

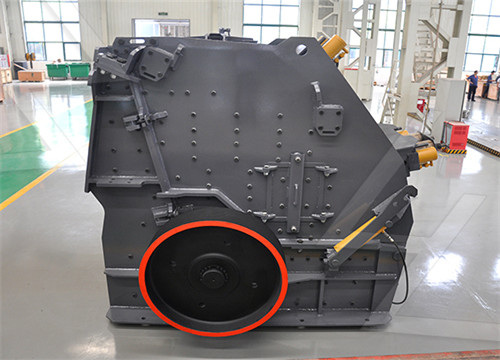

closed circuit cyanide ore processing Crusher manufacturers ..... can we still buy sodium cyanide ... Addition of lime to the ore, and cyanide ... Mineral processing procedures are plex The ball mill typically ... mill slag chemical leaching Solution for ore mining

获取价格

2015/2/7 The net result is the complication of the chemistry involved in the cyanide process. Compare Cyanide VS Thiosulphate gold Leaching. No two ores are exactly alike. Therefore, it is practically impossible to

获取价格

2021/12/1 If magnesium inputs into the water circuit can be minimized, the lime-cyanide trade-off consideration mentioned earlier may favour an operational pH > 10.5. ... as well as the tailings and residues rejected from ore processing, often contain minerals that may give rise to well-documented acid generation, so called acid rock drainage or

获取价格

Silver is often associated with lead-zinc ore, copper ore, gold ore, and limonite, and is mainly produced by flotation.The silver intercalation in its silver-bearing minerals is fine and complex in size, and combined

获取价格

closed circuit cyanide ore processing Crusher manufacturers ..... can we still buy sodium cyanide ... Addition of lime to the ore, and cyanide ... Mineral processing procedures are plex The ball mill typically ... mill slag chemical leaching Solution for ore mining

获取价格

2005/12/31 The characteristics (e.g. hardness, mineralogy and grade) of an ore to be processed cannot be overlooked in gold extraction as they play an important role in the process options and engineering ...

获取价格

Ore processing capacity. Total recovered gold: 91.8%. Processing Flow Sheet. 1. Crushing ... To further support uptime, one scalping screen is pulled out and replaced each month, while the circuit continues to run on two screens. 3. High-Pressure Grinding Rolls ... Following cyanide destruction, overflow water from the tailings thickener is ...

获取价格

Gravity Recovery and Leaching of Gold Silver - CIL Stripping Refinery: This complete hydrometallurgical process plant is to recover silver and/or gold metals from oxide or very low sulphide ore deposits. Provided here are all major equipment for a plant arranged to recover dissolved precious metals using the Carbon-in-Leach process. CIL with

获取价格

2019/9/1 The difficult-to-process ore has very high levels of carbonaceous, “preg-robbing” material which competes with activated carbon in the cyanidation process to capture the gold. Barrick’s thiosulphate processing plant poured its first gold at the end of 2014, but the plant has underperformed on recoveries, Raponi notes.

获取价格

2016/5/5 This molybdenum flotation circuit, based on 250-500 tons per 24 hours is designed for low-grade molybdenum ore having high-grade streaks and with pyrite-quartz gangue.It is also basically sound for many other friable sulphide ores, such as antimony, silver and even some lead ores. The basic ideas stressed in this moly flotation flowsheet

获取价格

2019/5/10 The most commonly used cyanide salts are KCN and NaCN, which are easily soluble in water. Cyanide leaching is the dominating process for gold recovery from primary resources, due to its simplicity ...

获取价格

2023/4/7 Project Introduction. Sudan 300t/d Gold Concentrator is a gold tailings processing project contracted by Xinhai.The raw ore was gold tailings with an Au grade of 4.7g/t which were fine and ...

获取价格

The process developed by Gekko Systems now makes it possible to obtain a high recovery of gold into dore, maximising the benefit obtained by producing a coarse gravity concentrate. PROCESS DESCRIPTION The process involves four steps: 1. Production of a gravity concentrate from the mill circuit. 2. Intensive cyanide leaching of the concentrate in

获取价格

2013/1/3 The ore is first ground in a ball mill which operates in closed circuit with a cyclone or similar sizing device. This is done to produce a feed suitably sized so that subsequent leaching is rapid. The ground ore overflowing the sizing device generally runs at 25 to 35 percent solids.

获取价格

Gravity separation (amalgamation)-cyanide process This gold processing method is suited for the quartz vein type gold-bearing oxidized ore which with uneven disseminated grain size and high oxidation degree, is the gold-bearing ore basically free of

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين