2016/4/7 Most crushers used for aggregate production can be categorised as one of three main types: Compression crushers – which

获取价格

A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are

获取价格

2024/5/30 Rock crushing equipment is a broad term. It refers to any machine that reduces large rocks into smaller pieces. These machines work by applying force to break

获取价格

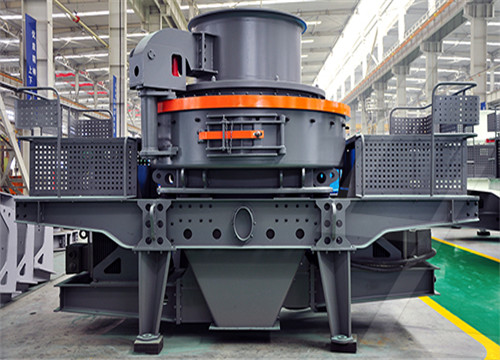

2024/4/19 There are two main types of impact crushers: horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). HSI crushers utilize a horizontal rotor that

获取价格

2023/1/16 Tertiary rock crushing is the last stage of the crushing process, where the crushed material from the secondary crusher is further reduced in size by a tertiary crusher to produce a product with a desired

获取价格

Jaw crushers – This type of crusher uses compressive force to break down concrete into smaller pieces. They are available in a large range of sizes, depending on how large the

获取价格

A jaw crusher is a type of compression crusher that is most commonly used for primary crushing. The material being crushed is squeezed between a stationary piece of steel and a moving piece of steel. This produces

获取价格

2018/9/10 Cone and gyratory crushers. Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is controlled

获取价格

2020/12/17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher.

获取价格

2020/3/19 JAW CRUSHERS Jaw crushers, which use a moveable jaw and a stationary plate designed to form a “V”, crush material using compressive force. These crushers offer an ideal solution for primary

获取价格

2021/3/25 Jaw Crushers feature a moving piece of steel (called the pitman) and a stationary piece of steel that form a V-shaped chamber. ... Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, ... They are a good tool to use in lower abrasive applications.

获取价格

2024/5/30 Understanding the different types of rock crushers and their uses is key to selecting the right equipment for your needs. Types of Rock Crushers There are several types of rock crushers, each with its unique mechanism and use. The most common types include jaw crushers, cone crushers, impact crushers, and gyratory crushers.

获取价格

2024/2/21 Other versions let you use both hands to rock or twist the tool to mince the garlic. There are also single-hand choppers with blades that cut the garlic to the desired size. Ease of Use. Depending on the type, materials, and quality, some garlic presses may be easier to use than others.

获取价格

2023/2/23 Portable rock crushers can be used to crush a variety of materials, including hard rocks, ores, and minerals. This makes them ideal for a wide range of applications, from mining and construction to landscaping and agriculture. ... There are three main types of portable rock crushers: jaw crushers, cone crushers, and impact

获取价格

Rock Crusher Types. Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business. We also custom-design top-performing crusher systems from the industry's best equipment that will work hard to make finished aggregate products like crushed stone, geosynthetic aggregates, sand and gravel, fertilizer, lime,

获取价格

Rock crushers are important tools for rock quarries and a variety of different types of construction and landscaping projects. Rock crushers are large pieces of equipment that break rocks into smaller, more workable pieces so that they can be used in

获取价格

2024/3/12 Jaw crushers are more rugged and handle steel better than impact crushers. The principle of how an impact crusher works is to impact and try to explode material. When steel, wire, and/or rebar are fed into an impact crusher, the machine could be damaged or wear out significantly faster than a jaw. ... The type of rock crusher you

获取价格

2020/12/17 Impact crushers use the principle of quick impacts to crush the material and they can be used in any stage of the crushing process. However, the features and capabilities of different impact crusher types vary considerably. Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and

获取价格

2022/9/5 Each type of crusher has its own specific benefits and drawbacks that need to be taken into account when choosing between types of crushers for a project. Using the wrong type of crusher can result in money wasted, damage to the equipment, and overall loss of efficiency. Here’s a look at how to select the right rock crusher for your next project.

获取价格

As with jaw crushers, these machines are compression crushers that use a stationary and moving piece of steel to break up the material. Cone crushers use a rotating head to crush the rock within a steel bowl. After initially being broken down in this manner, the material will travel through a narrow opening at the bottom of the bowl to achieve a finer grain size.

获取价格

2024/2/5 There are mainly two types of jaw crushers: the single toggle and the double toggle (or Blake crusher). The single-toggle jaw crusher features a moving jaw suspended on the eccentric shaft. It’s known for its efficiency in crushing but tends to be more susceptible to wear because of the high motion of the jaw.

获取价格

2016/10/23 ALLOY STEELS USED IN MAKING CRUSHERS. Manganese steel is mainly used for crushing-faces and other parts in actual contact with the stone. This alloy owes its pre-eminence to the property of work-hardening on its wearing face under the effects of pressure to a greater extent than any other metal; it also possesses

获取价格

2024/7/15 All types of crushers are widely used in gravel and aggregate fields, and they are often put in use after the excavation and blasting processes. Although their common and basic function is reducing large size of rock into small size, they are applied to different crushing stages like primary, secondary, tertiary, quaternary stages.

获取价格

A jaw crusher is a type of compression crusher that is most commonly used for primary crushing. The material being crushed is squeezed between a stationary piece of steel and a moving piece of steel. This produces

获取价格

2024/2/5 There are mainly two types of jaw crushers: the single toggle and the double toggle (or Blake crusher). The single-toggle jaw crusher features a moving jaw suspended on the eccentric shaft. It’s known for its efficiency in crushing but tends to be more susceptible to wear because of the high motion of the jaw.

获取价格

2016/10/23 ALLOY STEELS USED IN MAKING CRUSHERS. Manganese steel is mainly used for crushing-faces and other parts in actual contact with the stone. This alloy owes its pre-eminence to the property

获取价格

2024/7/15 All types of crushers are widely used in gravel and aggregate fields, and they are often put in use after the excavation and blasting processes. Although their common and basic function is reducing large size of rock into small size, they are applied to different crushing stages like primary, secondary, tertiary, quaternary stages.

获取价格

2023/2/28 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of

获取价格

Jaw crushers are versatile tools that can be used for many different purposes and offer critical advantages over other rock crushers. Whether you need to crush large rocks for construction or more minor materials for recycling, jaw crushers are an effective tool that can help you get the job done.

获取价格

The impactor family consists of two main types of impact crushers. The conventional type has horizontal shaft configuration, known as HSI. The other type consists of a centrifugal crusher with vertical shaft, generally known as VSI. Impactor operation is based on the principle of rapid transfer of impact energy to the rock material.

获取价格

The Crusher is built out of 12 special blocks made from a Block of Steel, Pistons, and Diamonds. If broken down, it takes 3 Blocks of Steel, 12 Pistons, and 12 Diamonds to build one Rock Crusher. Rock Crushers cannot be built adjacent to each other—there must be at least one tile in between Rock Crushers.

获取价格

Types of Crushers. Here we present the major types of crushers and how they work. Jaw Crusher. A jaw crusher is the most commonly used primary crusher. It uses simple technology to break down large blocks into smaller pieces. Their simplicity requires little engineering expertise to operate. A jaw crusher is reliable and needs less maintenance ...

获取价格

2024/2/18 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between

获取价格

2020/8/27 The crushers feature abrasion-resistant, high-strength, alloy steel teeth and a bolt-on replaceable tooth plate on the movable jaw. Power rotation of 360 degrees is optional.

获取价格

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing machines commonly used: mobile stone crushers and stationary stone crusher equipment. Stationary crushers include jaw crushers, impact

获取价格

2023/2/21 Aggregates: Jaw crushers are commonly used to crush aggregates such as gravel and sand for use in the construction industry. Hard rock: Jaw crushers are often used to crush hard rock ores such as gold and silver ores, copper ores, and iron ores. Recycling: Jaw crushers can also be used to recycle concrete, asphalt, and other

获取价格

2017/6/2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين