2024/4/26 These processes involve breaking down the mined ore into smaller fragments and separating it based on size. Let's explore the crushing and screening

获取价格

(o-grade iron ore) [1 , 34]. The crushing and screening separation technique reduces the runo mine into small sizes by breaking and separat-ing based on desired sizes. In this

获取价格

2024/4/1 Fig. 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings. Due to the characteristics of

获取价格

2023/12/1 1. Introduction. Due to the decreasing reserves of high-grade iron ore and secondary resources used for steelmaking, it has become an important research and

获取价格

2023/6/3 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the

获取价格

2024/1/16 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, Sept-Îles, Québec, Canada 2 WooDEM, Květoslava Mašity 291 CZ-25231 Všenory, Czech * e-mail:

获取价格

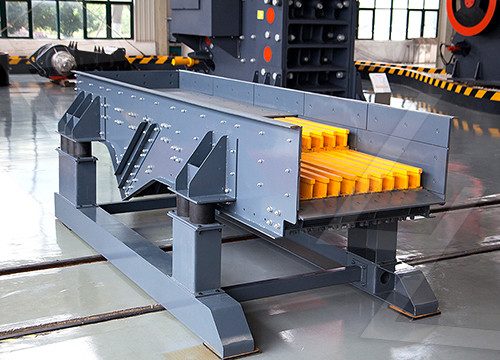

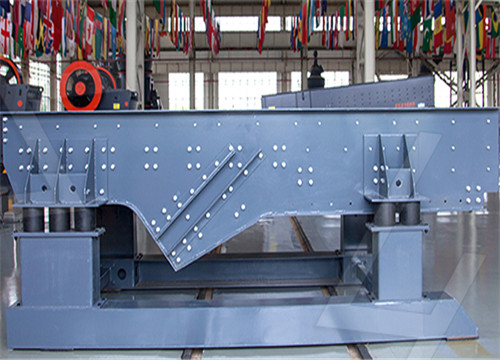

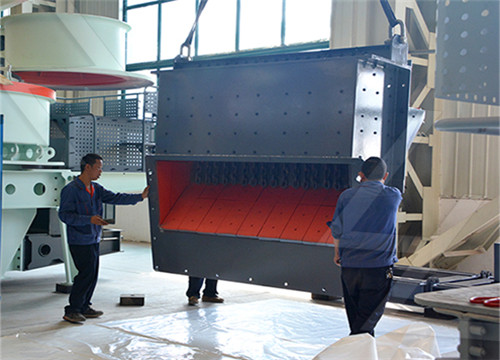

crushing. Stationary screens – an extensive range of complete screening solutions for scalping, closed circuit screening, fi nal sizing and de-watering. Single inclination,

获取价格

Process. Measurement-control for crushing and screening process is the measurement and control of key equipment and key process parameters to ensure the continuous,

获取价格

2017/3/3 Mechanical screening, often just called scr eening, is the practice of taking g ranulated ore material and. separating it into multiple grades by par ticle size. This is called as size control ...

获取价格

2022/1/1 Iron ore crushing and screening. Iron ore is one of the main raw materials to make steel. About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BF-BOF) route or through the electrical arc furnace (EAF) route. The majority of world crude steel is made from the BF-BOF route.

获取价格

2024/3/16 Iron ore is essential in steel making; however, high-grade ores have diminished, making low-grade ores inevitable. These low-grade iron ores need further beneficiation to upgrade the iron content. Currently, traditional physical and chemical methods are utilized and are not environmentally friendly. Bio-beneficiation techniques

获取价格

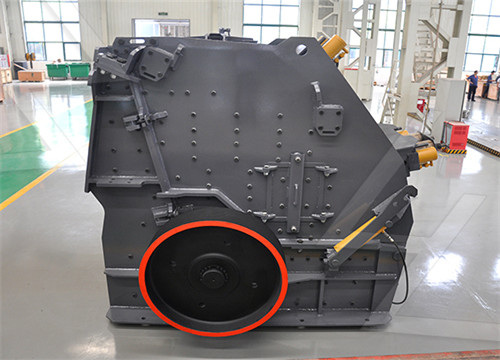

2012/10/15 Several considerations need to be taken into account in designing an efficient crushing and screening plant, the first being the raw materials to be crushed. ... tramp iron relief and automated product size

获取价格

2020/5/8 Ⅰ. Crushing and screening stage The crushing and screening stage in the industry is mainly composed of three-stage and a closed-circuit process. Gold ores need to go through coarse, medium, and fine crushing processes to be reduced into smaller pieces. The screening equipment is used to separate gold ores with proper size for the

获取价格

2023/12/19 High-grade hematite ore is referred to as direct shipping ore (DSO) as, once mined, the ore goes through a simple crushing and screening process before being exported for steel-making. ... Total Australian Ore Reserves of iron ore reported in compliance with the JORC Code were ... is approximately 94 Mt at 49.8% Fe (Davis

获取价格

Our fleet of mobile crushing and screening units provides you with on-site crushing and screening solutions, bringing the equipment directly to your project location. Additionally, we also offer mobile crushers for hire, allowing you to access our state-of-the-art equipment along with a certified operator. ... gold, iron ore, manganese and ...

获取价格

2024/4/26 Learn about the key stages in iron ore processing, including crushing, screening, and beneficiation techniques for optimal resource utilization. +86 13810565920; xlyin@xinhaimining; Follow us; Home; ... Crushing and screening are critical stages in the iron ore processing journey, as they prepare the ore for subsequent beneficiation ...

获取价格

Question: Modelling of a crushing and screening circuitQuestion 1.Application:To size material into 2 size classes before dense medium separationLarge Size fraction 50×10mm that goes to a dense medium drumSmaller size fraction 10×2mm goes to a dense medium cycloneFine "waste" material goes to the fine's beneficiation

获取价格

/ sbm iron ore recovery rates from crushing and screening.md. dushusbm c4a532c29b code. 2022-11-02 19:24:26 +08:00. 32 KiB Raw ...

获取价格

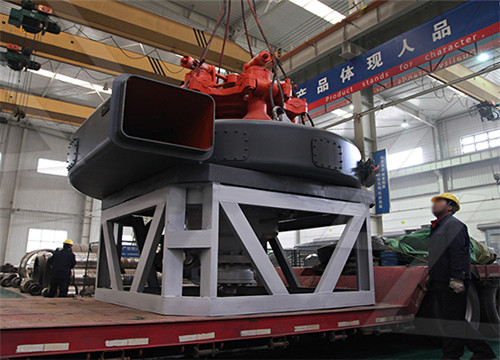

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance. This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability.

获取价格

(o-grade iron ore) [1 , 34]. The crushing and screening separation technique reduces the runo mine into small sizes by breaking and separat-ing based on desired sizes. In this method, the ne waste particles are ltered during the initial concentration, and the focus is made on the coarse materials with a high iron Fig. 1 Bio-leaching: a direct; b

获取价格

Iron Ore Conference Perth, WA, 20 - 22 August 2007 313 APPLICATION OF MOBILE PRIMARY CRUSHING AND BELT CONVEYING SYSTEMS FOR IRON ORE MINING FIG7 - Lokotrack LT160 crushing plant. Lokotrack type Approximate weight (t) Maximum feed size (mm) Minimum product size (mm) Typical capacity range (t/h) LT125 90 800 150

获取价格

/ sbm iron ore recovery rates from crushing and screening.md. dushusbm c4a532c29b code. 2022-11-02 19:24:26 +08:00. 32 KiB Raw ...

获取价格

Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance. This paper assesses a number of factors affecting the performance of the crushing plant by addressing the critical design parameters and consideration of ore characteristics, operability and maintainability.

获取价格

(o-grade iron ore) [1 , 34]. The crushing and screening separation technique reduces the runo mine into small sizes by breaking and separat-ing based on desired sizes. In this method, the ne waste particles are ltered during the initial concentration, and the focus is made on the coarse materials with a high iron Fig. 1 Bio-leaching: a direct; b

获取价格

Iron Ore Conference Perth, WA, 20 - 22 August 2007 313 APPLICATION OF MOBILE PRIMARY CRUSHING AND BELT CONVEYING SYSTEMS FOR IRON ORE MINING FIG7 - Lokotrack LT160 crushing plant. Lokotrack type Approximate weight (t) Maximum feed size (mm) Minimum product size (mm) Typical capacity range (t/h) LT125 90 800 150

获取价格

2024/1/1 It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control. Crushing Process Control. To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as

获取价格

BE international boasts extensive experience in crushing and processing ore mineralogies including gold, iron ore, manganese, detrital, chrome, quartz, nickel, kimberlite, and coal to name a few. Our vast crushing equipment fleet is available at a moment's notice and is convenient for short-term interventions typically required during planned ...

获取价格

2023/8/30 Alien Metals Ltd’s wholly-owned subsidiary, Iron Ore Company of Australia Pty Ltd (IOCA), has selected Crushing Screening Contractors Pty Ltd as its preferred supplier to undertake the crushing and screening operations at the flagship Hancock iron ore project in the Pilbara of Western Australia.

获取价格

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size.. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.. A method of separating solid particles

获取价格

sbm/sbm iron ore crushing and screening recovery rates.md -rw-r--r-- 27.7 KiB View; Log; Blame; View raw; Permalink; 8318c03c — maekesi push 4 months ago. View Rendered; View Source ...

获取价格

2018/7/11 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

获取价格

The Itakpe iron ore processing plant in Nigeria presently produces a tail sometimes containing up to 22 iron recovery fine iron minerals iron ore processing plant wastes blending dilution Nigeria crushing stage and a dewatering system most suitable for coarseiron ore recovery rates from crushing and screening,RIO TINTO IRON

获取价格

2022/5/24 Experiments show that the froth flotation separation has a pretty high recovery rate. ... Copper Ore Crushing and Screening Equipment in Zambia. ... Iron ore pellets are made of iron ore into 8 ...

获取价格

iron ore crushing and screening recovery rates 2021-05-27T23:05:27+00:00 iron ore recovery rates from crushing and screening. screening method for iron ore iron ore crushing and screening recovery rates Iron ore Iron ore crushing and screening plant is also known as mobile iron ore crusher and is the portable ; recovery of limestone

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين