2016/10/18 A heuristic approach for in-pit crusher and conveyor system’s time and location problem in large open-pit mining. ... Cost efficiency and high reliability of In-Pit Crushing and Conveying (IPCC) system make it more appealing to be used in deeper

获取价格

2020/9/1 1. INTRODUCTION. With the trend of open pits becoming broader and more profound in scale continuing, the potential of In-Pit Crusher and Conveyor (IPCC)

获取价格

2018/3/1 In pit crusher conveyor systems. Strategic mine planning. Resource recovery. Surface metalliferous mining. Mine optimization. Truck and shovel. 1. ...

获取价格

2011/10/24 The SMIPCC is a system where the in-pit crusher is located in the pit and is relocated after 1-2 years, depending on the operations of the specific mine (Tavakoli et al. 2011; Hay et al. 2019 ...

获取价格

2014/7/12 FIG 1 – Fully mobile in-pit crusher and conveyor, beltwagon and bench conveyor at Yimin He Mine, China (T K Holdings Limited, 2015). ... an unplanned delay or maintenance outage in one piece of equipment will affect the throughput of the entire system. As a result, system availability decreases as the number of ...

获取价格

Maintenance ; 348 . 52 ; Productivity Factors. Power factor . 2.90 ; Meters drilled per tonne blasted . 138 . ... By placing a crusher in the pit on Bench 28, some 290 metres below the pit perimeter, and ... Figure 3: Crusher . Main Incline Conveyor . Drive System . The main incline conveyor (11-06-01) is the second highest tension belt of a ...

获取价格

the bench conveyor needs to be shifted, the transport crawler will be used to reposition the semi-mobile beltwagon and the conveyor drive station. This new continuous open pit mining system will be the first of its kind in China. The fully mobile in-pit crusher is a new development from ThyssenKrupp, which, the company says, “will be the ...

获取价格

Employ a maintenance technician. A dedicated employee on staff can help keep your conveyor running smoothly. They will maintain service records and spare parts. Most importantly, they will know how the conveyor runs. The maintenance technician will have the answers and skills to keep the conveyor running and reducing any down time. Spare

获取价格

2016/1/14 Telsmith's T300 cone crusher delivers 300-hp performance and a crushing capacity output range from 125 to 400 metric tph for quarry applications. ... subscribe to Pit Quarry to receive more articles just like it. ... (Van der Graaf): Maintenance-Free Conveyor Belt Drives Aug 13, 2024. Available from Motion: SKF Spherical Roller

获取价格

2013/12/1 As open cut mines become progressively deeper, mining operations face increased operating costs and technical challenges. In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre.

获取价格

2018/3/1 In pit crusher conveyor systems. Strategic mine planning. Resource recovery. Surface metalliferous mining. Mine optimization. Truck and shovel. 1. ... Depending on the type of IPCC system used, labor requirements can be as low as 80 people, including operators and maintenance personnel [3]. Exact numbers will vary

获取价格

A mobile crusher operating in a multiple-bench pit can feed a mobile Horizontal Conveyor with full-length receiving hopper. From here, material can be conveyed via Ramp Portables or via up-bench conveyors (each with Super Portable® technology) out of the pit and onto an overland conveying network.

获取价格

2013/12/1 As open cut mines become progressively deeper, mining operations face increased operating costs and technical challenges. In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre.

获取价格

2024/5/25 Maintenance of Rock Crusher Conveyor Belt. Regular maintenance of rock crusher conveyor belts is essential to ensure their longevity and optimal performance. Maintenance activities include regular conveyor belt inspections to check for signs of wear, damage, or misalignment. Cleaning the belt and removing any debris that may have

获取价格

Trust Metso with your mine electrification program. Metso’s productized Foresight™ SMPG and Foresight™ overland conveyor range offers the highest energy efficiency and productivity and combined with our application software - the William Conveyor Explorer and Crush and Convey Resource Center - make IPCC planning easier, cheaper and

获取价格

The first serious step was the introduction of in-pit crushing in the early 1980s. With in-pit crushing accepted as a standard design mode, the energy saving ... product ranging in size from -300 mm for conveyor transport, or -200 mm for SAG mill feed. ... • Lowest maintenance per ton processed of any crusher design.

获取价格

Conveyor system The conveyor system transports the crushed material to the dumping site or the processing plant. Conveyors can be designed stationary, relocatable or shiftable for bench and dumping operations. In particular open pit applications including high-incline and curved conveyor systems can be offered by thyssenkrupp in

获取价格

2024/5/25 Maintenance of Rock Crusher Conveyor Belt. Regular maintenance of rock crusher conveyor belts is essential to ensure their longevity and optimal performance. Maintenance activities include regular conveyor belt inspections to check for signs of wear, damage, or misalignment. Cleaning the belt and removing any debris that may have

获取价格

Trust Metso with your mine electrification program. Metso’s productized Foresight™ SMPG and Foresight™ overland conveyor range offers the highest energy efficiency and productivity and combined with our

获取价格

The first serious step was the introduction of in-pit crushing in the early 1980s. With in-pit crushing accepted as a standard design mode, the energy saving ... product ranging in size from -300 mm for conveyor transport, or -200 mm for SAG mill feed. ... • Lowest maintenance per ton processed of any crusher design.

获取价格

Conveyor system The conveyor system transports the crushed material to the dumping site or the processing plant. Conveyors can be designed stationary, relocatable or shiftable for bench and dumping operations. In particular open pit applications including high-incline and curved conveyor systems can be offered by thyssenkrupp in

获取价格

Crusher automation – ensures consistent and effi cient operation. Improves productivity and product quality while reducing maintenance costs by preventing overload situations. Stationary conveyors – a complete range of belt conveyors. Wide variety of widths, lengths, accessories and options. Various models incor-

获取价格

2018/8/11 The Telsmith Inc. T400 T-Series™ Cone Crusher is ideal for secondary and tertiary circuit positions with 400 hp, a 12” maximum feed size, and throughput capacities ranging from 138 up to 594 mtph. Hydraulic Relief and Clearing lets uncrushable materials pass through large clearing circuits safely and quickly.

获取价格

2021/11/16 A significant product launch in the in-pit crushing and conveying (IPCC) space was announced in parallel with the headline-grabbing co-operation agreement signed by Metso Outotec and FAM GmbH in June.. On the same day the two companies shook hands on a global non-exclusive pact to deliver integrated end-to-end solutions for IPCC

获取价格

2017/2/16 The 11-million-euro contract included a nearly 400-ton Lokotrack LT200 mobile jaw crusher – the biggest ever built – with a nominal capacity of 2,500 tons per hour.

获取价格

2014/1/11 In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre. Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective

获取价格

2017/5/21 Built with all the rugged performance and durability of our standard 4043T, the 4043TR Recirculating Impact Crusher offers two additional functions: A large two-deck screen, fed directly from the crusher, delivers sized product off the fines conveyor

获取价格

2021/12/23 The 1400-CCS includes the 1400-45 OC plant with a side-discharge conveyor, 6 x 20 screening plant with an integrated feed conveyor, return conveyor with a cleated belt and three, radial stacking conveyors. It may be configured in a variety of ways to meet individual producers’ needs.

获取价格

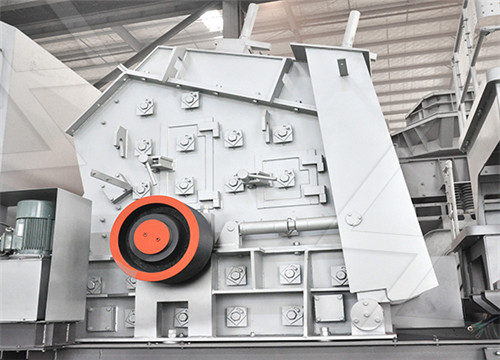

2023/1/31 The primary crusher is mainly divided into gyratory crusher, jaw crusher, hammer crusher, etc. In addition to its own buildings and equipment, the primary crushing station also needs supporting facilities, such as upper ore bin, lower ore bin, conveyor gallery, oversize component gallery air raise, dedusting chamber, measurement

获取价格

2013/6/10 Chassis come with a 54-in. under-crusher conveyor with hydraulic head fold. In addition, Masaba offers standard and customized portable plants; single- and dual-screen plants; wash plants with standard and rollaway

获取价格

Proactive maintenance avoids costly repairs now and downtime in the future. Contact us today to learn more about how our factory and safety-trained techs can help you keep up with your crusher, screen, and conveyor maintenance.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين