For example, the STEINERT FinesMaster directly combines two serial magnetic separators with one eddy current separator, producing an incredibly efficient and compact machine

获取价格

Iron ore – they are used to separate magnetic minerals from non-magnetic minerals by removing the magnetic fraction from the non-magnetic material, which results in a high-grade concentrate. Industrial

获取价格

2023/3/9 It is also possible to adjust the induction distance between the disks at all levels and the mineral particles to be selected to obtain different magnetic field induction intensities to achieve one-time

获取价格

High-intensity magnetic separators, or multi-roller magnetic separators, are iron removal/magnetic separation equipment for sorting weak magnetic minerals.It is widely used in limonite, manganese ore, and beach sand

获取价格

The dry magnetic separator is used for sorting dry magnetic minerals, and is mainly used for selecting large-sized, coarse-grained ferromagnetic ores and fine-grained weak

获取价格

Knowing what magnetic properties your minerals contain allows you to more effectively design processes and equipment to further concentrate the feed or to remove waste

获取价格

2024/4/26 Iron ore processing is a crucial step in the production of steel, one of the most essential materials in modern society. Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined

获取价格

Iron ore – they are used to separate magnetic minerals from non-magnetic minerals by removing the magnetic fraction from the non-magnetic material, which results in a high-grade concentrate. Industrial

获取价格

Introduction. Capacity: 0.5-180 t/h Wet drum magnetic separator is a commonly used and widely used magnetic separation equipment for iron and manganese ore in mineral processing plants. Separating magnetic

获取价格

Wet High Intensity Magnetic Separators (WHIMS) from Multotec apply magnetism, matrix rotation and gravity to achieve para-magnetic materials separation. Applications include heavy minerals, ilmenite, manganese and iron ore (haematite) beneficiation; PGM upgrading as well as manganese recovery from slimes dams.

获取价格

2024/8/14 The concept of magnetic separation Magnetic separation is a beneficiation method that uses the difference of mineral magnetism to separate different minerals in a non-uniform magnetic field. The magnetic separation method is usually used for the beneficiation of metal ores. The use of magnetic separation for non

获取价格

2017/4/20 This, I think, was the first use of magnetic iron-ore concentrates in a blast furnace. The small machine was of the belt type. Mr. Ball soon after designed a drum-type machine, and later a double-drum machine in which a three-part separation was made. There are now magnetic machines of many types, but the majority use the alternating

获取价格

2019/3/18 The presence of Ca 2+ / Mg 2+ could affect the surface potential of minerals during the flotation process. Still, the adsorption mechanism of these ions on specific crystal planes has yet to be fully understood. The surface potential of the scheelite (112) and (001) surfaces, under the effect of Ca 2+ /Mg 2+ at pH 8 and 11, were

获取价格

2022/2/28 A dry high-intensity magnetic separator is a waterless separation machine introduced to separate weakly magnetic particles that DLIMS cannot process. ... Dry magnetic separation of iron ore of the bakchar deposit. Procedia Chem. 15 ... S.K., Banerjee, P.K., Suresh, N., Murthy, Y.R., Singh, V.: Dry high-intensity magnetic

获取价格

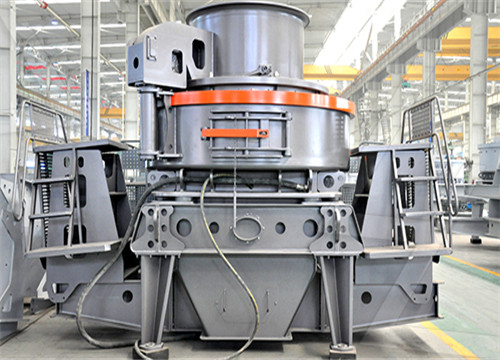

High-intensity magnetic separators, or multi-roller magnetic separators, are iron removal/magnetic separation equipment for sorting weak magnetic minerals.It is widely used in limonite, manganese ore, and beach sand mineral processing. This magnetic separator uses a strong magnetic field to effectively dry separate ferromagnetic

获取价格

The separation of chromite ore with lowest particle size fraction was done using Mozley mineral separator followed by the magnetic separation of the sink product by magnetic separator. The results obtained revealed about 77% of the total material containing 300 μm particle size, 52% ˂ 212 μm and 17% below 75 μm.

获取价格

Ore processing is the process of separating valuable minerals from its ores by beneficiation equipment. Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, magnetic separation, electrostatic separation and more. JXSC provide full mining

获取价格

2024/4/29 Applications of Magnetic Separation: The versatility of magnetic separation extends its application across various industries: 1. Iron Ore Processing: Magnetic separation is widely used in iron ...

获取价格

JXSC provide mineral separation equipment including flotation machines, magnetic separators, electrostatic separators, etc.Among them, magnetic separators are diversified, mainly including wet drum, high-intensity, three-disc, flat plate, and high-gradient, slurry magnetic separators.It’s suitable for removing iron impurities and purifying various metal

获取价格

2021/6/26 If you want to separate the two minerals with strong magnetism and weak magnetism, the magnetic force of the strong magnetic mineral must be greater than the combined force of the mechanical force in the opposite direction to the magnetic force, and the magnetic force of the weak magnetic mineral It must be less than the resultant

获取价格

Introduction: Electrostatic separation is a physical beneficiation method that utilizes the different electrical properties of various minerals and materials for separation. A drum-type and ARC-type electrostatic separation machine is commonly used electrical separation equipment. The most suitable granularity of the selected materials for the drum-type

获取价格

2024/4/29 Applications of Magnetic Separation: The versatility of magnetic separation extends its application across various industries: 1. Iron Ore Processing: Magnetic separation is widely used in iron ...

获取价格

JXSC provide mineral separation equipment including flotation machines, magnetic separators, electrostatic separators, etc.Among them, magnetic separators are diversified, mainly including wet drum, high-intensity,

获取价格

2021/6/26 If you want to separate the two minerals with strong magnetism and weak magnetism, the magnetic force of the strong magnetic mineral must be greater than the combined force of the

获取价格

Introduction: Electrostatic separation is a physical beneficiation method that utilizes the different electrical properties of various minerals and materials for separation. A drum-type and ARC-type electrostatic separation machine is commonly used electrical separation equipment. The most suitable granularity of the selected materials for the drum-type

获取价格

2024/8/14 If the associated mineral is iron oxide, the magnetic separation method can be used to realize the separation of tin and iron. Wet strong magnetic separation is the main method, which is used before the original ore, secondary concentrate and concentrate enter the gravity separation operation; If the associated mineral is tungsten

获取价格

JXSC wet drum magnetic separator has a rugged construction that can withstand abrasive materials and corrosive environments. Its rotating drum design allows continuous material flow through the magnetic field, effectively capturing iron particles and delivering a high-purity end product.; We support custom equipment or adjustable magnetic field strength

获取价格

Capacity: 0.15-10t/h Feeding size: 0.02-0.3mm Application: fine-grained gold, iron, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphorite, tungsten ore, tin ore, tantalum-niobium ore, minerals with different specific gravity, other non-ferrous metals, rare metals and non-metallic minerals separation; and also be used for placer mining on seashores,

获取价格

We also provide demagnetising solutions that reverse the residual effects that magnetic separation has on the magnetic viscosity of ferrous slurries, allowing them to return the mineral stream to an acceptable viscosity for downstream processing. These demagnetising coils generate a magnetic field that alters magnetic orientation at 200 Hz.

获取价格

2024/8/14 Mining magnetic separator is common equipment in mineral processing. And magnetic separation is the main method of iron ore dressing. What minerals are required for magnetic separation? Common Iron Minerals are magnetite (strong magnetic minerals), hematite (weak magnetic minerals), Limonite, specularite, siderite (all weak

获取价格

2024/8/14 Each process has its advantages and disadvantages when separating limonite ore. Gravity separation offers a low-cost method but may need help recovering fine particles or efficiently removing impurities.Magnetic separation is highly selective but requires large equipment and may produce tailings with lower iron grades.Flotation has

获取价格

Introduction: The three-disc magnetic separator is suitable for precisely separating various magnetic mineral mixed ores. It is mainly used to separate fine-grained weakly magnetic materials from non-magnetic materials, such as ilmenite, monazite, tungsten and tin, tantalum-niobium ore, and other dry separation operations. The induction distance

获取价格

Capacity: 8-35 t/h Application: Mainly used for wet separation of various weakly magnetic metal minerals such as magnetite, hematite, limonite, garnet, ilmenite, tungsten ore, and iron removal process of silica sand and kaolin.

获取价格

2024/3/5 Magnetic Separator can be either dry or wet. The magnetic separator can also be classified as permanent or electromagnet magnetic separator. Magnetic separator for mineral processing industry falls into three basic categories: low, medium and high intensity, based on the relative magnetic field strength employed to accomplish

获取价格

In the iron ore beneficiation process, high-intensity magnetic separation is used for minerals with low magnetic susceptibility, while lowintensity magnetic separation is used for minerals with ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين