2024/6/18 Generally speaking, Jaw Crushers tend to be more cost-effective for primary crushing applications, while Cone Crushers may command a higher price due to

获取价格

2024/3/20 Jaw crushers are usually louder than cone crushers because of the back-and-forth motion of the movable jaw and the way the material slams against the crushing plates. Cone crushers, on the other

获取价格

2024/2/20 3. Production Capacity. Throughput Needs: High-volume projects might benefit more from jaw crushers, which can process large amounts of material quickly. Impact crushers, while efficient, may have a

获取价格

The main difference between these two types of machines is how efficiently they break down materials. Jaw crushers are better at small-size rocks and grits, while impact crushers are better at larger chunks (up to 2 inches in

获取价格

2022/11/21 In terms of volume, jaw crusher is smaller than cone crusher. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3

获取价格

Cone crushing main advantages: High productivity, less power consumption, work more stable, small vibration crushing ratio, product granularity is more uniform, any side can give ore, and can be crowded

获取价格

The 30×62 Grizzly King Jaw Crusher size is designed with recycling in mind. Gradation is less of a focus with this jaw crusher size, instead intended to run less aggressively to

获取价格

2024/7/15 If ton/hr; 161.7(gape in meters)∧2, use a jaw crusher. If ton/hr>161.7(gape in meters)∧2, use a gyratory crusher. 2. Differences in installation and maintenance ... VS cone crusher Horizontal shaft impact

获取价格

2016/2/28 Features of the Jaw Crusher. Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory,

获取价格

2020/8/21 Aggregate equipment expert Dave Phelan goes in depth about two popular crushing options so you can decide which on is right for you. For more information on ...

获取价格

PDF On Sep 20, 2020, Ekin Koken and others published COMPARISON OF SECONDARY CRUSHING OPERATIONS THROUGH CONE AND HORIZONTAL SHAFT IMPACT CRUSHERS Find, read and cite all the research you need ...

获取价格

2019/5/30 The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers. Cone crushers have traditionally been used as secondary and ...

获取价格

2020/12/30 Using a jaw crusher and a cone crusher in Snowstorm gravel pit. Join Philip Watson as he explains how Road Base is made. Using a jaw crusher and a cone crusher in

获取价格

2. Different in production characteristics. Generally, jaw crusher and cone crusher has the following production characteristics: Feeding size: The feeding size of jaw crusher is relatively large, and it can generally handle materials below 1200mm, which the feeding size of cone crusher is relatively small, generally below 560mm. Production capacity: cone

获取价格

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a

获取价格

2015/4/1 The reason impact crushing has not been developed in this way before is because most manufacturers produce both cone crushers and impact crushers, and each product is focused on its own market segment. Moreover, cone crushers are more expensive to purchase than impact crushers and provide greater returns for manufacturers.

获取价格

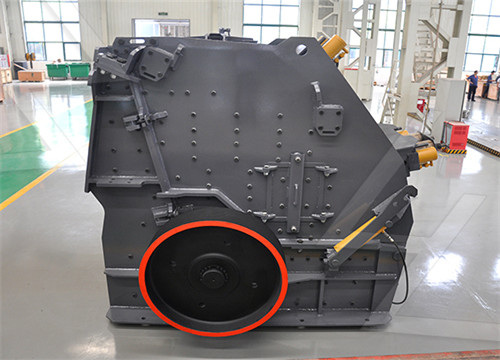

The working mode of jaw crusher is a curved extrusion type, and the material is crushed by compression in the crushing chamber composed of a moving jaw and a fixed jaw. Impact crusher adopts impact crushing principle, where the material is repeatedly impacted and crushed between the rotor (plate hammer) and the impact plate.

获取价格

2022/11/21 Among these crushers, jaw crusher and cone crusher have similar crushing principle, but different in many ways. Lets’ talk about the differences between jaw crusher and cone crusher. Jaw crusher: preferred for coarse crushing. Jaw crusher has the advantages of simple structure, high reliability of continuous operation and low price.

获取价格

mechanism in cone crushers that has a profound impact on the aggregate morphology. Rajan and Singh [4] investigated the variations in rock aggregate morphology produced by various crusher circuits.

获取价格

2023/10/20 Jaw Crusher vs. Cone Crusher. Cone crushers have a wide range of uses and high crusher efficiency. Cone crushers are divided into three types: coarse crushing, medium crushing and fine crushing according to the scope of use. Standard type cone crusher – medium crushing equipment; Fine crushing equipment – short-head

获取价格

2017/7/26 Activities at the primary stage will depend on gyratory, jaw or impact crushers. Cone crushers, roll crushers and impact crushers are mostly used at the secondary stages. The tertiary and quaternary stages mostly require the utilization of cone crushers, although some functions may require vertical-shift impact crusher.

获取价格

2022/11/21 Among these crushers, jaw crusher and cone crusher have similar crushing principle, but different in many ways. Lets’ talk about the differences between jaw crusher and cone crusher. Jaw crusher: preferred for coarse crushing. Jaw crusher has the advantages of simple structure, high reliability of continuous operation and low price.

获取价格

mechanism in cone crushers that has a profound impact on the aggregate morphology. Rajan and Singh [4] investigated the variations in rock aggregate morphology produced by various crusher circuits.

获取价格

2023/10/20 Jaw Crusher vs. Cone Crusher. Cone crushers have a wide range of uses and high crusher efficiency. Cone crushers are divided into three types: coarse crushing, medium crushing and fine crushing according to the scope of use. Standard type cone crusher – medium crushing equipment; Fine crushing equipment – short-head

获取价格

2017/7/26 Activities at the primary stage will depend on gyratory, jaw or impact crushers. Cone crushers, roll crushers and impact crushers are mostly used at the secondary stages. The tertiary and quaternary stages mostly require the utilization of cone crushers, although some functions may require vertical-shift impact crusher.

获取价格

2020/9/16 When compared with cone crushers, impact crushers often have a lower capital cost, but can potentially incur high operating costs if the application has not been evaluated properly and has high abrasive qualities. ... Compression crushers such as cones and jaw crushers normally have lower reduction ratios than HSI or VSI crushers, but do

获取价格

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material

获取价格

2023/2/23 When it comes to crushing equipment in the mining industry, two popular options are gyratory crushers and cone crushers. While both types of crushers are designed to crush rock and other materials, there are significant differences between them. In this article, we'll explore the key differences between gyratory crushers and cone crushers,

获取价格

2024/6/26 Whether you choose a cone crusher, an impact crusher, or a jaw crusher, you can trust our products to deliver superior performance and reliability. Explore our full range of crushers at Rokbro and contact our team of experts for personalised assistance in selecting the best equipment for your operations.

获取价格

2024/4/19 This way is frequently applied in jaw crushers and cone crushers. In jaw crushers, the material is squeezed between the fixed jaw and the moving jaw. ... Cubical particles are the primary products of cone and compression crushers, while impact crushers usually generate the angular particles. 2. Gradation Requirements: ...

获取价格

2020/12/17 Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the material. Jaw crushers, gyratory crushers and cone crushers operate according to the compression principle. Impact crushers, in turn, utilize the impact principle. Another way to classify the equipment is ...

获取价格

2021/2/22 Hydraulic vs mechanical. Hydraulic types of puller are easier to operate than their mechanical equivalents, but you will need a pump, hose, and gauge. Depending upon the size of the puller, the pump may be powered by hand, air, or electric. Reach. The reach is the available distance between the pulling surface of the jaw and the jaw head

获取价格

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material

获取价格

In aggregate processing plants, jaw, cone and im-pact crushers are most commonly used. At the initial stages of crushing, jaw or cone crushers are usually used. The advantages of the jaw crusher are the low ... 1 – fixed jaw, 2 – moving jaw, 3a, 3b – toggle plates, 4 – pitman, 5 – eccentric shaft,

获取价格

2023/2/21 While jaw crushers have their own set of advantages and disadvantages, they are often compared with other types of crushers, such as impact crushers, cone crushers, and gyratory crushers. In general, jaw crushers are a good option for applications where the material is relatively hard and where a high degree of reduction is required.

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين