Iron Ore Conference Perth, WA, 20 - 22 August 2007 313 APPLICATION OF MOBILE PRIMARY CRUSHING AND BELT CONVEYING SYSTEMS FOR IRON ORE MINING

获取价格

Crushing plant design should accordingly provide for laydown and workspace for onsite equipment refurbishment and repair. Where possible, equipment manufacturers should

获取价格

DEFINITION. The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be

获取价格

2023/3/31 Iron ore crushing station generally consists of four parts of equipment: feeding equipment, crushing equipment, buffer silo, and unloading equipment. Feeding equipment is also divided into silos,

获取价格

2023/12/16 Step 7: Build the plant. The plant can then be built according to the construction plans. Step 8: Commission the plant. Once the plant is built, it can be

获取价格

2023/6/3 In the practice of production, the crushing and screening process is related to the particle size of raw ore, the particle size of final crushing products, and the scale

获取价格

The raw material is extracted from the iron ore mine and transported to the primary crusher. This is where the initial crushing takes place, reducing the size of the ore into

获取价格

2023/12/1 The coating material used in this work was Hadfield steel, ASTM A128 grade C [15], applied for the manufacture of mantle and concave coatings that were

获取价格

The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be provided with almost any type of primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher.

获取价格

In about 1950, railroad runs became longer with the opening if the Sherman crushing/sizing plant. Ore was brought to this facility from the Fraser, Forester, Sharon and other mines in the Sherman Group and from the

获取价格

gold industry and a move to contract crushing in the iron ore industry the demand for larger equipment grew. This has accelerated so that even modest-sized direct-shipping iron ore (DSO) projects are using mobile crushing plant based on innovative designs from vendors. The attractions are flexibility, mobility, capital cost savings and the ability

获取价格

2024/4/26 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction. The most common method of ironmaking is the blast furnace route. In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the top.

获取价格

MAX Plant produces custom modular, fixed, mobile and portable crushing, screening, conveying and mineral processing equipment in Australia. We work with crushing contractors, site owners and operators to design and manufacture the perfect crushing, screening and mineral processing solutions for your application. ... Iron Ore. Recycling ...

获取价格

Stone Crusher Machine Cost, Ore Crushing Plant Equipment Price; Stone Crusher Used in India for Sale with High Performance Cost Ratio; The application of High cost-performance ratio LM vertical mill in slag powder production; In South America; Construction Grinding Mills Help You Achieve New Development in Low-Carbon Energy; SBM Brazil

获取价格

2018/7/11 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking.

获取价格

2023/12/1 These coatings, installed in a crusher, were used to process iron ore with a maximum particle size is 55 mm and a. Results and discussion. Conical crushers have a rotating shaft, whose protective coating is called the mantle. A crusher works by rotating and crushing the iron ore against a surface, which is also a coating and is called the

获取价格

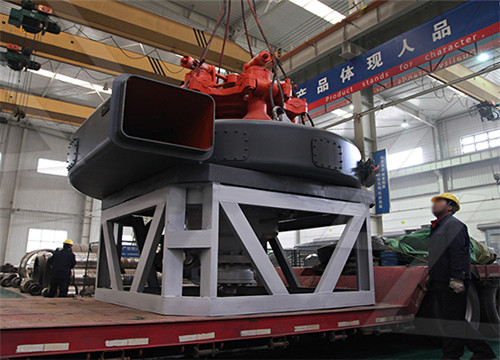

Liming heavy industry supply the iron ore crushing plant with capacity 800tph which including the primary jaw crusher, impact crusher, cone crusher and vibrating feeder and other auxiliary equipment for the iron ore crushing plant. ... HPC220 cone crusher application in gold mining in Ghana. Gold reserve overview in Ghana: Ghana is well

获取价格

The red colour usually allows you to spot it from a distance: iron ore. The volcanic rock is mainly used in the manufacture of steel. India has vast reserves of iron ore and is the second biggest steel producer in the world. The mobile screening plants MOBISCREEN EVO from are used during the extraction of the important material.

获取价格

2021/3/25 The material and its characteristics, e.g., its hardness, density, shape and condition, will affect the type of crusher that needs to be used. Knowing the material characteristics as well as the advantages and limitations of the different crusher types will help to determine the best primary crusher for a given application.

获取价格

The cost of a Iron Ore Process Plant can vary widely depending on its size, capabilities, and complexity. Most of the price of Iron Ore Process Plant ranges from US $ 500 to $ 159999 per Piece. It's important to research and compare different models and features to find the best Iron Ore Process Plant for your needs and budget.

获取价格

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc., but the advantage is only partial

获取价格

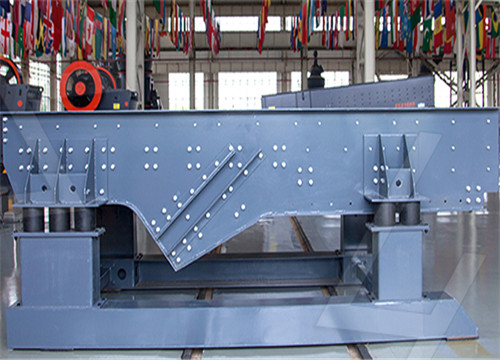

Types: Small portable jaw crusher with vibrating screen; Small portable jaw crusher with belt conveyor; Small portable hammer crusher; Application: The small portable rock crushers widely used to crush and screen various rocks, stone, aggregates, construction materials and ores, including limestone, granite, marble, gypsum, basalt, iron ore,

获取价格

2021/3/25 The material and its characteristics, e.g., its hardness, density, shape and condition, will affect the type of crusher that needs to be used. Knowing the material characteristics as well as the advantages and limitations of the different crusher types will help to determine the best primary crusher for a given application.

获取价格

The cost of a Iron Ore Process Plant can vary widely depending on its size, capabilities, and complexity. Most of the price of Iron Ore Process Plant ranges from US $ 500 to $ 159999 per Piece. It's important to research and compare different models and features to find the best Iron Ore Process Plant for your needs and budget.

获取价格

2014/4/3 Fig 3 Types of processing ores. The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore. The wet process consists of multi-stage crushing followed by

获取价格

Types: Small portable jaw crusher with vibrating screen; Small portable jaw crusher with belt conveyor; Small portable hammer crusher; Application: The small portable rock crushers widely used to crush and screen various rocks, stone, aggregates, construction materials and ores, including limestone, granite, marble, gypsum, basalt, iron ore,

获取价格

Mineral processing plant including crushing facilities; Associated infrastructure includes onsite water supply and in-pit dewatering bore fields, explosives storage, maintenance and administration facilities, haul and access roads, and a run of mine pad ... Assessment report for the application of ML for the Buzzard Iron Ore Project ...

获取价格

iron ore crushing plant application In iron ore processing plants, crushers are used to perform comminution up to a defined range for the next stage of the process, grinding. It is very common to use tapered crushers, and the crushing occurs within a cavity called the chamber, whose capacity is defined by the distance between the concave and ...

获取价格

Contribute to naicha22/2022 development by creating an account on GitHub.

获取价格

2022/8/18 Innovation has an important role in improving the productivity, safety and sustainability of mining operations. Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies. The innovative

获取价格

2021/3/15 Dust emission is one of the critical problems of the mining industry. Dust emission can cause respiratory diseases among workers and adjacent residents of the factory and environmental pollution in the region. This study aims to reduce dust emissions of an iron ore concentrate plant in Iran. Applying dust control methods can affect the

获取价格

Royal Engineering is one of the leading Manufacturers of Crushing Plant across the world. Since 1995 we have been leading manufacturer and supplier for Crushing Plant, Crusher Machine, Jaw Crusher, Grinding, Screening, Conveying Equipment, also Mineral processing plant equipments for the field of Mines, Quarry, Minerals, Chemicals, Pharmaceuticals,

获取价格

3 Screening machines for iron ore and coal. The crushing and screening systems for iron ore processing vary widely, depending on whether a magnetite or hematite deposit is being mined. While good quality magnetite is now dry-processed, hematite from deposits below the water line requires wet processing due to sticky quartz and clay contaminations.

获取价格

Application: Quarry, Mining Ore, Construction Project. Capacity: 0-100/ 100-200/ 200-300/ 300-500/ 500-700/ 700-1000T/H ... Limestone. Granite. Cobblestone. Marble. Iron Ore. Copper Ore. Concrete Wastes. Asphalt Wastes. Stationary Crushing Plant . Stone crushing plant is designed to crush rocks and minerals, typically constructed at a

获取价格

Our Iron Ore Crushing Plant is equipped with high-quality crushers and screens, allowing for efficient processing and sorting of large volumes of iron ore. Whether you need a complete crushing plant or individual components, we can customize our solutions to meet your specific requirements. ... Lead zinc ore has a wide application in electric ...

获取价格

2023/6/3 In the practice of production, the crushing and screening process is related to the particle size of raw ore, the particle size of final crushing products, and the scale of the mineral processing plant. The application of modern measurement and control for crushing and screening process is beneficial to improving the quality of products and the ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين