2023/2/28 Primary vs. Secondary Crushers: While primary crushers are responsible for breaking down larger rocks and stones into smaller particles, secondary crushers are used to further refine these particles

获取价格

2020/3/19 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm,

获取价格

2024/3/25 The capacity of a crusher is how much it can crush in a certain amount of time, often talked about in tons per hour. Secondary crushers can handle from 50 to 300 tons per hour, depending on the

获取价格

Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers –

获取价格

2024/7/17 Types of crushers. Crushing is a multi-stage process that includes primary crushing, secondary crushing, and tertiary crushing. Different types of crushing

获取价格

The world's most popular modern cone crushers. HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity

获取价格

2023/2/28 The two most common types are horizontal shaft impactors (HSI) and vertical shaft impactors (VSI). HSI crushers are designed for primary or secondary

获取价格

2019/9/2 PQ University Lesson 7: Crushing Secondary Breaking. In the quarry, crushing is handled in four potential stages: primary, secondary, tertiary and quaternary. The reduction of aggregate is spread

获取价格

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1.

获取价格

2019/9/2 2. About how much output can a jaw crusher typically produce in an hour? 3. What type of technology is slowly replacing some stationary plants in quarries? 4. What type of crusher is most similar to a

获取价格

MoleDive Secondary Crusher can crush 60-548 tons of materials per hour, with a maximum feed size of up to 1000mm. Compared to traditional impact crushers, it significantly improves the crushing ratio. ... (kg)

获取价格

2014/9/23 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm, or 200mm, depending on the size of the crusher. ... allowing

获取价格

2015/12/16 Cone crusher and short head cone: feed diameter < 25 cm; reduction ratio 5:1 to 10:1 usually 7:1; capacity 5 to 300 kg/s: Mohs hardness < 8. Usually secondary or tertiary crusher. Impact crusher pulverizers, shredders or smooth roll: feed diameter 1 cm with a reduction ratio of 7:1 to 10:1; capacity 0.3 to 50 kg/s.

获取价格

grinding production and complete plant plan...Secondary Crusher Pulverisette 13 5 Kg Hour Crush To. that can crush stone to 350 microns; EquipmentRock crusherRock to 212 micron 183; secondary rock mining millscrushed to minus 5 mm by a jaw crusher More Henan Mining Machinery and Equipment Manufacturer. special crushers to crush and

获取价格

sbm / sbm secondary crush mobile.md. 28 KiB Raw Permalink Blame History Unescape Escape. This file contains unexpected Bidirectional Unicode characters! This file contains unexpected Bidirectional Unicode characters that may be processed differently from what appears below. If your use case is intentional and legitimate, you can safely ignore ...

获取价格

secondary crusher 5 kg hour crush Secondary crusher pulverisette 13 5kg hour crush to 1 microns crusher spesifiion kg hour flavioplafonnage Mobile Cone Crushers, Mobile Cone Crusher Series Weight kg (lbs) Optimum feed size mm (in) QH441 Mobile hydrocone crusher: CH440: 50,488 (111,307) 215 (85) QH332 Mobile hydrocone crusher:

获取价格

Generally the machines have to be rigid enough to crush also hard inclusions. As the reduction ratio is only about 5:1 a 2-stage crushing is required in most applications. ... Single – rotor hammer crushers are built for throughputs to up to about 2000t/hour. For example, a well known machine of this capacity has a rotor of 3300 mm width and ...

获取价格

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m; Product: -300mm (for transport) to -200mm (for SAG mill)

获取价格

2021/4/16 A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per ...

获取价格

The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for making graded material that is going on to be used on government projects. ... Gyratory crushers and cone crushers are both types of compression crushers that crush materials by squeezing them between a ...

获取价格

Jaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as ... Weight kg 14500 17500 17800 21820 40500 lbs 32000 38600 39160 48100 89300 17 High ... MEKA Secondary impact crushers feature a unique combination of heavy rotor design, wear material and crushing chamber ...

获取价格

Taking into account formula (5) and table 2, the coefficient of energy of destruction of granite will be 0.446 J/m3 or, in terms of kg, 1.16 kJ/kg.

获取价格

2023/2/28 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them. Discover case studies and examples of successful applications, as well as future

获取价格

The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for making graded material that is going on to be used on government projects. ... Gyratory crushers and cone crushers are both types of compression crushers that crush materials by squeezing them between a ...

获取价格

Jaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as ... Weight kg 14500 17500 17800 21820 40500 lbs 32000 38600 39160 48100 89300 17 High ... MEKA Secondary impact crushers feature a unique combination of heavy rotor design, wear material and crushing chamber ...

获取价格

Taking into account formula (5) and table 2, the coefficient of energy of destruction of granite will be 0.446 J/m3 or, in terms of kg, 1.16 kJ/kg.

获取价格

2023/2/28 Learn about the different types of secondary crushers, including impact crushers, cone crushers, roll crushers, and jaw crushers, and their functions, advantages, disadvantages, applications, and factors to consider when selecting them. Discover case studies and examples of successful applications, as well as future

获取价格

The output from the secondary crusher and the throughs from the secondary screen are transported by conveyor to the tertiary circuit, which includes a sizing screen and a tertiary ... PROCESSING OPERATIONS (kg/Mg) a . Source . b. Total Particulate Matter . r,s. EMISSION FACTOR RATING Total PM-10 EMISSION FACTOR RATING Total PM-2.5

获取价格

GECO Secondary Jaw Crusher 30x10, For stone/coal, Capacity: 32 - 55 Tph ₹ 11.50 Lakh. Geco Grinding Centre. Contact Supplier. Mild Steel 48"x36" (1200x950mm) - Primary Jaw Crusher ₹ 65 Lakh. ... 300 kg/hour. Brand: S.R Fab Engineering Works. Automation Grade: Semi-Automatic. Power Source:

获取价格

2016/1/10 It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest. The power consumption of a machine or installation is usually expressed in kw.-hours per ton as being the most convenient method.

获取价格

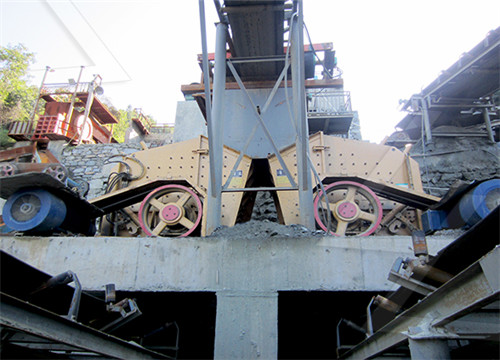

2023/2/28 The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher. The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1. The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness,

获取价格

2014/2/1 Taking into account formula (5) and table 2, the coefficient of energy of destruction of granite will be 0.446 J/m3 or, in terms of kg, 1.16 kJ/kg.

获取价格

The crushing and drive technology of the Crush + Size double roll crusher ensures crushing results far beyond the previously known limits of a roll crusher. ... Primary and secondary crusher for concrete recycling. 22. May 2023. read more. Dec 9 2022. BAUMA 2022 ... Crush + Size Technology GmbH Co. KG. Kölner Straße 94 D-51702 ...

获取价格

2016/2/17 From Allis-Chalmers’ Superior Primary and Secondary Crushers. ° Actual required depends on stone hardness, reduction ratio, and so on. If a 60-in. gyratory crusher is to process material from a quarry where a shovel loads the raw material, the shovel would probably have to have a dipper capacity of at least 5 cu yd to be compatible.

获取价格

secondary stage because it significantly reduces the risk of blockage to ensure an ... HP Series cone crushers 5. The ® HP Series™ for aggregates ... Total crusher weight 6,470 kg (14,300 lbs) 12,160 kg (26,800 lbs) 18,100 kg (39,900 lbs) 25,600 kg (56,400 lbs) 37,000 kg

获取价格

2024/3/25 The capacity of a crusher is how much it can crush in a certain amount of time, often talked about in tons per hour. Secondary crushers can handle from 50 to 300 tons per hour, depending on the type and how you use it. ... The feed size means the biggest piece the crusher can crush. Secondary crushers usually can crush pieces

获取价格

2019/1/1 The coarse aggregates obtained by different crushing mechanisms (jaw and impact crushers) show very similar characteristics in terms of binder content assessed by acid leaching (27.5 and 26.6 wt.%), water absorption (8.76 and 9.75 wt.%) and porosity (18.6 and 20.2 vol.%).Thus, it is not possible to conclude that any of these mechanisms

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين