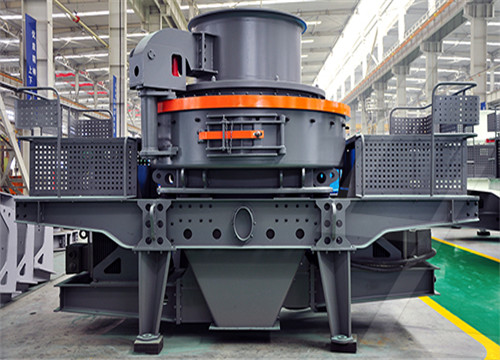

95% or greater uptime. 50% less footprint vs ball mill (In same application) Up to 50% less media consumption. < 2 weeks to install. < 85 db noise. 4. Metso Vertimills®. n fine wet

获取价格

Grinding efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner wear make Vertimill® the lowest total cost of ownership

获取价格

Methodologies for the evaluation of grinding media consumption rates at full plant scale. 2004 • Jaime Sepulveda. Download Free PDF View PDF. ... Vertimill grinding and classification zones Vertimills can be either top

获取价格

Open the catalog to page 3. A versatile and energy efficient solution Metso Vertimill® is the industry benchmark in gravity induced milling technology. Globally recognised as efficient grinding machines, they bring

获取价格

2019/4/8 The energy consumption obtained for grinding in the pilot tests was compared with that reported by Donda and Bond. The SSSAG route had the lowest energy consumption, 11.8kWh/t and the SAB route ...

获取价格

Description. Vertimill® is globally recognized as an energy efficient grinding machine. Through a low total cost of ownership, they bring substantial improvement to the profitability of concentrators. During the

获取价格

For a mill of a given size, speed and charge filling, the rate of size reduction of ore particles depends on (i) the frequency of grinding media collisions (ii) the probability of capture of ore ...

获取价格

grinding media, receiving the same feed stream, being fed the same tonnage rate and achieving the same fineness of grind. The results of the study showed a Vertimill

获取价格

2019/3/5 Based on a review of the Vertimills currently in operation and a comparison of their efficiency and media consumption relative to a ball mill, Metso estimates that approximately 1.48 million MWh of energy

获取价格

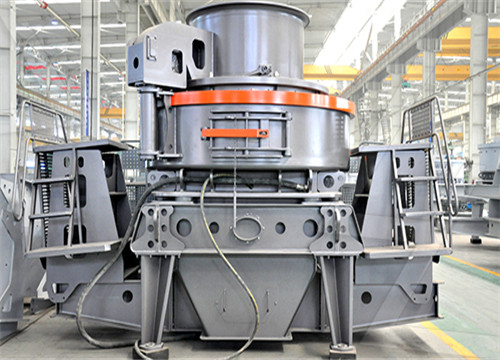

Vertimill Functional Description The Vertimill is typically arranged in closed circuit and fed by the cyclone underflow. The motor power turns the Vertimill screw at constant speed to stir the grinding balls and slurry.

获取价格

During the years, Vertimill® technology has proven to be efficient especially in secondary and tertiary grinding, regrinding, fine grinding, and lime slaking applications. Vertimill® is a unique product offered exclusively by Metso Outotec. Grinding efficiency, reduced media consumption, lower installation cost,

获取价格

During the years, Vertimill® technology has proven to be effi-cient especially in secondary and tertiary grinding, regrinding, fine grinding, and lime slaking applications. Vertimill® is a unique product offered exclusively by Metso Outotec. Grinding efficiency, reduced media consumption, lower installation cost, minimal main-

获取价格

Methodologies for the evaluation of grinding media consumption rates at full plant scale. 2004 • Jaime Sepulveda. Download Free PDF View PDF. Minerals Engineering. ... Vertimill grinding and classification zones Vertimills can be either top fed (the new feed is introduced into the top of the mill via a feed pipe that deposits the feed just ...

获取价格

vertimill grinding media consumption rates kg. grinding media costs and the need to discriminate between steel and magnetite in coarse. Application of Vertimill fine grinding technology at.. Consumption rates for power wear and other consumables labor and maintenance and. CO2 emission 1.0 kg per kWh of electricity CO2 tax 23 per t of CO2 ...

获取价格

2015/9/1 The grinding efficiency of this plant was recently verified through a sampling campaign and the results showed that the measured specific energy consumption was similar to the predicted specific ...

获取价格

Metso Vertimill® is the industry benchmark in gravity induced milling technology. Globally recognised as efficient grinding machines, they bring substantial improvement in profitability of concentrators. Up to 50% less media consumption < 85 db noise 4

获取价格

Contribute to dinglei2022/en development by creating an account on GitHub.

获取价格

2004/1/1 A silver/lead/zinc mine in Queensland, Australia was originally designed to treat 1.5 million wet metric tonnes per annum. The original grinding circuit consisted only of primary autogenous milling.

获取价格

Ball Mill Vertimill Media Unit 25mm 25mm Power Draw kW 3,350 2,010 Running Hours h/year 8,059 8,059 Energy Consumption MWh/year 27,000 16,200 Media Consumption t/year 2,735 2,735 Energy Pricing CAD/kWh 0.200 0.200 Grinding Media Pricing CAD/t 1,000 1,250 Energy Cost kCAD/year Grinding Media Cost kCAD/year Total Cost

获取价格

Table 4 – Simulation results for the initial expansion option – 65% pebble ports open area in the AG mill Feed Rate (t/h) 347 365 U/F split to Vertimill (%) 75 50 Mill charge % 41.46 41.35 ...

获取价格

grinding circuits. The benefits the Vertimill offers in terms of lower energy consumption and lower media consumption are well established and documented; such benefits can significantly improve the viability of a new project, plant expansions or upgrading grinding mills that need to be replaced.

获取价格

grinding media, receiving the same feed stream, being fed the same tonnage rate and achieving the same fineness of grind. The results of the study showed a Vertimill required 44% less power than the

获取价格

2018/10/1 The relationship between the available volume for slurry and the VertiMill® power is shown in Fig. 1.The relationship as shown in the figure was validated by survey data collected from a mine site (Palaniandy, 2014) where the entire mill grinding media was weighed after a crash stop.The survey data showed good agreement with the developed

获取价格

Table 4 – Simulation results for the initial expansion option – 65% pebble ports open area in the AG mill Feed Rate (t/h) 347 365 U/F split to Vertimill (%) 75 50 Mill charge % 41.46 41.35 ...

获取价格

grinding circuits. The benefits the Vertimill offers in terms of lower energy consumption and lower media consumption are well established and documented; such benefits can significantly improve the viability of a new project, plant expansions or upgrading grinding mills that need to be replaced.

获取价格

grinding media, receiving the same feed stream, being fed the same tonnage rate and achieving the same fineness of grind. The results of the study showed a Vertimill required 44% less power than the

获取价格

2018/10/1 The relationship between the available volume for slurry and the VertiMill® power is shown in Fig. 1.The relationship as shown in the figure was validated by survey data collected from a mine site (Palaniandy, 2014) where the entire mill grinding media was weighed after a crash stop.The survey data showed good agreement with the developed

获取价格

2016/3/30 The Vertimill VTM1500 also has a significantly lower grinding media consumption. The media consumption of processing the raw ore dropped from 0.8 kg/t to 0.3 kg/t, equivalent to a 60% reduction. With an annual output of 800,000 tons of iron concentrate, the savings in grinding media alone can amount to RMB 2.4 million Yuan

获取价格

2015/3/15 Davey, G., 2006. Fine Grinding Applicants Using the Metso VertiMill Grinding Mill and the Metso Stirred Media Detritor... Holloway, B., Clarke, G., Lumsden, B., 2008. ... (~100 kg m −3), much higher fluxes were attained with coarser PSDs at both higher concentrations and lower dosages. When flocculating slurries of the seven PSDs at a

获取价格

2018/8/1 When looking at VTM machines with manual doors, discharging the grinding media poses significant safety risks. In the field, we’ve seen clients attempt to open the door using makeshift solutions such as long chains and other devices. This can lead to media spillage, endangered maintenance workers, and cause problems for

获取价格

2017/4/29 The original ball load in the mill was 6614 lb. (3000 kg.) and the load at the end of the 694 hr. was 6338 lb. (2874.8 kg.). During this time, 590 lb. (267.6 kg.) of balls less than 3 in. (76.2 mm.) in diameter were discarded from the mill. The screen analysis of the ball charge at the end of the operation is shown in Table 20.

获取价格

2024/4/18 Vertimill ® grinding mills are part of Metso’s Planet Positive offering and provide up to 40% better energy efficiency than ball mills. The robust and vertical design benefits customers through long component lifetimes and as much as a 50% reduction in plant footprint. ... Vertimill ®, HIGmill™, and Stirred Media Detritor (SMD) allowing ...

获取价格

2020/10/1 Vertimill® is an energy-efficient grinding machine. They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns. ... Significant savings in flocculant consumption could be made June 27, 2024 June 24, 2024 admin 0. Product News . Modernization of blast furnace A at

获取价格

vertimill grinding media consumption rates kg. vertimill for dry grinding - trinivastnl. vertimill grinding media consumption rates kg Vertimill For Dry Grinding India hotelsiddharthajmerin In the wet grinding process of a stirred media mill the bead . Get Quote vertimill grinding samac - noa4lifenl. vertimill grinding samac - leehosea ...

获取价格

2024/4/17 Metso Corporation’s press release on April 17, 2024, at 09:00 a.m. EEST. Metso is excited to introduce the world’s most powerful vertical screw type stirred mill, the Metso Vertimill ® 7000. Developed as a solution to lower total cost of ownership, the large mill allows for more available grinding power.One Vertimill® 7000 grinding mill

获取价格

To get energy efficient grinding below approx. 40 µm you need to have finer grinding balls than are suitable for the tumbling mill. So, the case for the stirred media mill that often has media in the range 5-10 mm if used as a tertiary grinding step or for re-grinding.

获取价格

2013/9/5 In comparison to traditional ball mills, in fine and regrind applications, the VERTIMILL® mills can perform the same grind with 30% to 50% less energy and significantly lower grinding media ...

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين