Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores. These devices

获取价格

2022/1/1 Low-grade iron ore mined from the earth is usually composed of several minerals, desirable and undesirable. Magnetic separation means applying a magnetic

获取价格

2023/12/1 Utilizing magnetic separation is an important step towards achieving green and low-carbon steel production. In China, every 1% increase in iron ore

获取价格

With the STEINERT MRB you achieve high-value material extraction of ferromagnetic metals in the fine grain range. Our two-stage magnetic separator therefore combines a

获取价格

2022/1/1 The first SLon-2500 vertical ring-pulsating high gradient magnetic separator was designed and built up in 2006. It was installed at the tails dam of Hai Nan

获取价格

2015/12/31 Abstract. This chapter introduces the principle of how low-grade iron ores are upgraded to high-quality iron ore concentrates by magnetic separation. Magnetite

获取价格

Stage 1: A weak magnet and a high-belt speed – scalping process removes ferromagnetic material. Stage 2: A medium-strength magnet and/or slower belt speed – removes

获取价格

Flocculators. Compact, powerful units use magnets to speed settling of magnetic solids from slurries and liquids for easier recovery and separation. Used widely in the iron and

获取价格

2021/6/26 Today, I will share with you the magnetic separation process of iron ore. Magnetic Separation Principle. ... Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the

获取价格

Multotec supplies a complete range of magnetic separation equipment that effectively separates ferromagnetic and paramagnetic particles from dry solids or slurries. Magnetic separators are renowned for their

获取价格

The Reading Rare Earth Magnetic Drum (RED) uses a unique 5 pole magnetic element to generate a field intensity in excess of 0.7 Tesla on the drum skin. The magnetic element design affords the maximum field

获取价格

2017/5/22 ABSTRACT. High intensity dry magnetic separators are in use for various applications in the mineral as well as coal processing industries. Evaluation of the performance of these separators treating different minerals has

获取价格

2022/1/1 This chapter introduces the principle of how low-grade iron ores are upgraded to high quality iron ore concentrates by magnetic separation. Magnetite is the most magnetic of all the naturally occurring minerals on earth and can be readily extracted by low-intensity magnetic separators from magnetite ores. On the other hand, oxidized

获取价格

2017/4/12 A tower containing magnetic ore separator at Edison's Ogdensburg, N.J mine. Courtesy: National Park Service, Edison National Historic Site. ... The plant had three magnetic separators that could produce a total of 530 tons of refined ore. There was other equipment to re-refine what was left over to extract even more ore. But technical

获取价格

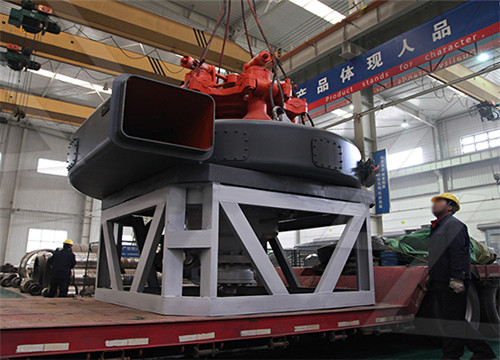

Magnetic Separator Working Video. Introduction of Magnetic Separator: Magnetic separator is the professional refinement and iron removal equipment that can be used in the magnetic iron ore the dressing process such as magnetite, hematite, magnetic pyrite and limonite and non-metallic materials iron removal working including coal, quartz and

获取价格

1. Efficient Separation: Magnetic separator can efficiently separate mineral particles with magnetic properties, allowing valuable minerals to be easily extracted. 2. Wide Applicability: It is suitable for various ores and materials, including magnetite, magnetic pyrite, roasted ore, ilmenite, as well as coal, non-metallic minerals, construction materials, and other

获取价格

This series of products has an ul- tra-high background magnetic field that cannot be achieved by ordinary electromagnetic equipment, and can effectively separate weakly magnetic substances in fine-grained minerals.It is suitable for beneficiation of rare met- als, non-ferrous metals and non-metal- lic ores, such as cobalt ore enrichment, impurity

获取价格

From traditional and trusted magnetic separation equipment, right through to innovative sensor sorting technologies, we help our customers achieve their goals with sustainable solutions. ... when it is necessary to protect equipment from tramp iron in material recovery facilities or to process iron ore efficiently, we offer tailor-made magnet ...

获取价格

2023/12/1 Utilizing magnetic separation is an important step towards achieving green and low-carbon steel production. In China, every 1% increase in iron ore concentrate grade increases blast furnace utilization factor by 2% to 3%, coke consumption by 1.5%, and limestone consumption by 2% [34].

获取价格

Through different magnetic circuit designs and rotation speed options, our dry drum magnetic separators deliver high grade concentrate, middlings and tailings quantities. Our Dry Drum Magnetic Separators features: Ideal for cobbing iron ore beneficiation or banded iron stone removal on a diamond plant

获取价格

2022/12/14 The process stages are detailed, providing information on some characteristics of the magnetic separation equipment. The plant capacity is estimated based on technical and economic criteria. ... Ezhov, A.; Shvaljov, Y. Dry magnetic separation of iron ore of the bakchar deposit. Procedia Chem. 2015, 15, 160–166.

获取价格

An upstream, weak-field magnetic drum initially extracts fine, clean iron from the material flow. The residual fraction from the first magnetic stage passes via a discharge directly onto a downstream, fast-running magnetic separator equipped with strong neodymium permanent magnets.

获取价格

2023/12/1 Utilizing magnetic separation is an important step towards achieving green and low-carbon steel production. In China, every 1% increase in iron ore concentrate grade increases blast furnace utilization factor by 2% to 3%, coke consumption by 1.5%, and limestone consumption by 2% [34].

获取价格

Through different magnetic circuit designs and rotation speed options, our dry drum magnetic separators deliver high grade concentrate, middlings and tailings quantities. Our Dry Drum Magnetic Separators features: Ideal for cobbing iron ore beneficiation or banded iron stone removal on a diamond plant

获取价格

2022/12/14 The process stages are detailed, providing information on some characteristics of the magnetic separation equipment. The plant capacity is estimated based on technical and economic criteria. ...

获取价格

An upstream, weak-field magnetic drum initially extracts fine, clean iron from the material flow. The residual fraction from the first magnetic stage passes via a discharge directly onto a downstream, fast-running magnetic separator equipped with strong neodymium permanent magnets.

获取价格

equipment,suchasmaterialhandlingsystems,crushers,andmills.Thistypeofsepa- ... Tramp iron magnetic separator is able to remove large particles up to 2 m in size success-fully. When selecting the required protective magnet, parameters such as the shape and size of iron pieces as well as the material handling system have to be taken into

获取价格

Mineral concentration based on.magnetic properties of the minerals contained in the ore. Magnetic Protection Equipment. ... Application of intermittent current to the cross-belt separator arose from the need for the dry separation of an iron composition material from the copper in a product submitted by personnel of a Bureau of Mines ...

获取价格

2023/3/9 Among them, the most magnetic is magnetite. The demand for iron ore by various iron and steel enterprises has grown rapidly, further stimulating the development of the iron ore beneficiation industry. Magnetic separation is one of the main beneficiation methods of iron ore beneficiation, and magnetic separator is the main equipment of

获取价格

2017/1/1 Finally, the magnetic component of the roasted ore can be recovered by magnetic separation after being liberated from gangue minerals. Many pilot-scale suspension magnetizing roasting and magnetic ...

获取价格

Slon has specialized in magnetic separator manufacturing since 1987. [email protected] +86-0797 ... Manganese Ore HGMS; Copper-cobalt HGMS; Feldspar HGMS; Silica Sand HGMS; Waiting for Updating; Iron Ore Magnetic Separator; Magnetic Separation. Wet Magnetic Separation; Dry Magnetic Separation; ... and its research on magnetic

获取价格

The removal of “tramp“ iron from feed belts can also be regarded as a form of low-intensity magnetic separation. However, tramp iron removal is usually accomplished by means of a magnetic pulley at the end of an ore conveyor (Figure 13.12) or by a guard magnet suspended over the conveyor belt (see Chapter 2).Tramp iron removal is important prior

获取价格

2017/6/4 WHIM is the short acronym for Wet High Intensity Magnetic Separation. At present, most U.S. iron raw materials are produced from magnetic taconites, which are ground to a nominal minus 270 mesh (53 micrometers), beneficiated by wet low-intensity magnetic separation, and pelletized. The taconite ore bodies generally contain 19 to 25

获取价格

2024/8/14 Mining magnetic separator is common equipment in mineral processing. And magnetic separation is the main method of iron ore dressing. ... Wet Permanent Magnetic Drum separator is a kind of magnetic separator often used in iron ore concentrators. It is suitable for separating high magnetic minerals. According to the

获取价格

2023/3/1 The experimental equipment and steps are shown in Fig. 1. 100 g of slag powder was weighed and placed in a magnesium oxide crucible.It was then placed in a muffle furnace (MoSi 2 resistance heating) at 1500 °C for 90 min, cooled to 1350 °C at a rate of 1 °C/min and held for 90 min, cooled to 1100 °C at 1 °C/min, then cooled to 800 °C at

获取价格

2024/3/15 1. Introduction. In arid and severely cold regions such as west China, a plenty of iron ores are difficult to be economically utilized due to water scarcity [1, 2], so that the utilization for such iron ores has an urgent demand for high-efficient dry magnetic separation (DMS) technology [[3], [4], [5], [6]].A large portion of iron ores were currently

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين