INFORMATION AND RELATED FILES GAR-BRO 10 CF QUAD GT BALL MILL BUCKET, DWG G07-116.PDF GAR-BRO 10 CF QUAD GT PIVOT

获取价格

Our PERI AutoCharge Mill Grinding Ball Charging System is designed to provide a controlled continuous supply of balls to maintain consistent ball loading in the grinding mill. Continuously charging grinding balls will allow your mill to maintain a consistent power draft, charge volume, ore feed rate, or consumption average (kg/t).

获取价格

2018/12/18 Mill ball charging systems have undergone little change during the past two decades. Most operations utilize a locomotive/ball car combination to load and haul charges from the ball storage bin to the

获取价格

2018/2/16 After a mill run, the mill jar is opened and the contents are carefully poured into the separation bucket screen, which is resting in the receiving bucket. After placing a lid loosely on the top of the separation

获取价格

2017/2/13 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for

获取价格

Available cylinder sizes range from laboratory mills to 12′ in diameter.. Discharge Features. For discharge of the product on wet grinding processes we offer our standard media retention grate along with an adequate size discharge valve. For discharge of the product on dry grinding processes we offer our dry media retention grate and housing. ...

获取价格

This design uses heavy duty support rollers to drive the rotation of the mill shell directly. Depending on the, the drive and support rollers can be polyurethane lined rollers or a series of rubber tyres. Bulk Handling Techonolgies can design and supply roller mounted ball mills with capacities ranging from 500 kg/hr up to 25 TPH in a single mill.

获取价格

Standard: Extended hopper: Power supply: 380 – 420 Vac 50Hz 25A (440 – 480 Vac 60Hz 25A) 380 – 420 Vac 50Hz 25A (440 – 480 Vac 60Hz 25A) Hopper capacity

获取价格

2015/10/9 Calculating a grinding circuit’s circulating loads based on Screen Analysis of its slurries.. Compared to %Solids or Density based Circulating load equations, a more precise method of determining grinding circuit tonnages uses the screen size distributions of the pulps instead of the dilution ratios.Pulp samples collected around the ball mill or rod

获取价格

2021/11/1 Several approaches have been proposed to detect mill load, including active power, vibration (Davey et al., 2012, Xie et al., 2013, Zhao et al., 2013), acoustic sensors (Jackson et al., 2014, Pax, 2001), toe and shoulder angles (Clermont et al., 2008, Millsense, 2021). Vibration method is the most widely used one for in-situ measurement,

获取价格

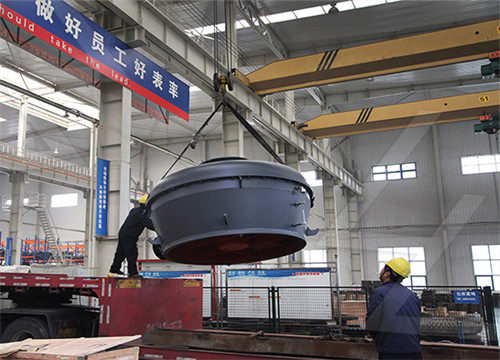

2017/3/1 To assist with loading and unloading of these steel balls, they use a kibble system. More importantly, this provides a safe and easier way to charge mill chutes or inlets. In consultation with our client, we can design a kibble system to ensure it is suitable for the application and also in accordance with Australian Standards.

获取价格

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Dry Mill - The general operation of a grinding mill is to have the product impacted between the balls as ...

获取价格

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power

获取价格

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Dry Mill - The general operation of a grinding mill is to have the product impacted between the balls as ...

获取价格

The rotational speed of the ball mill drum directly affects the milling process. Higher speeds increase the kinetic energy of the grinding media, resulting in more violent collisions and finer grinding outcomes. However, excessively high speeds may cause excessive wear and tear on the mill components. 3. Fill Rate

获取价格

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product.

获取价格

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power

获取价格

Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of

获取价格

The rotational speed of the ball mill drum directly affects the milling process. Higher speeds increase the kinetic energy of the grinding media, resulting in more violent collisions and finer grinding outcomes. However, excessively high speeds may cause excessive wear and tear on the mill components. 3. Fill Rate

获取价格

For ball mill, reasonable ball loading not only affects the improvement of grinding efficiency and productivity, but also relates to the service life of ball mill. Therefore, it is very important to master the reasonable ball loading quantity and the ball loading ratio of the ball mill in the process of using the ball mill.

获取价格

2017/7/3 In the cylindrical mill the work of the rationed ball load was about 60 percent better than the Davis ball load, and when the mill which was lined with truncated cones was used there was a further gain of about 5 percent. ... A better plan was to permit the drag sand to fall into buckets and at set intervals to pass the sand back to the new

获取价格

Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer. n by Thomas Holzinger, Holzinger Consulting, Switzerland BALL MILLS 1 FEBRUARY 2021 INTERNATIONAL CEMENT ...

获取价格

2013/8/2 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor ... title="Calculate and

获取价格

12TH AUSIMM MILL OPERATORS’ CONFERENCE / TOWNSVILLE, QLD, 1–3 SEPTEMBER 2014 FUNCTIONAL PERFORMANCE OF BALL MILLING CIRCUITS – A PLANT METALLURGIST’S TOOL FOR PROCESS CHARACTERISATION 229 with the higher circulating load ratio had coarser mill feed and mill discharge, thus, more of the

获取价格

2017/7/3 The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load. Rods in place weigh approximately 400 pounds per cu. ft. and balls in place approximately 300 pounds per cu. ft.. Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill ...

获取价格

The processing capacity of the ball mill increases with the increase of the filling rate of the steel ball. It increases the probability of grinding the ore and the self-grinding effect. When the ball filling rate is 45%, the ball mill load is the largest, and when it exceeds 45%, the load is greatly reduced as the filling rate increases.

获取价格

The Magotteaux ball loading machine enables to load the grinding media into a tube mill in a very fast (15-25 tph) and safe way. The machine is operated by 1 worker and increases the operational safety; The loading speed significantly reduces the mill downtime and saves a substantial amount of time and money;

获取价格

Simply place a sample in the rotating bucket with six steel charges. The bucket will rotate 600 times at a speed of 58-62 rpm, for approximately 10 minutes. After the rotation is complete the mass of the remaining aggregate is weighed and compared with the original weight to determine the WBM value.

获取价格

Ball Mill Charging System - 911metallurgist. Mill ball charging systems have undergone little change during the past two decades. Most operations utilize a locomotive/ball car combination to load and haul charges from the ball storage bin to the mill charging boxes or, alternatively, transport charges to the charging boxes by means of a ball bucket

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين