2020/6/8 ML Process optimization can be performed by generating a database with satisfactory number of experiments followed by modeling the physical correlation between process parameters and the process

获取价格

2022/9/7 The flotation tests were carried out in a Metso model D-12 cell (Helsinki, Finland). ... V. Development of online soft sensors and dynamic fundamental model-based process monitoring for complex

获取价格

2021/3/1 All flotation tests were performed in duplicates. Flotation experiments were carried out at neutral pH (=7), stirring speed at 325 rpm and the air flow (7 L/min)

获取价格

the flotation recovery of Ni, Cu and Co from a nickel-copper sulphide ore. The effect on flotation performance of various parameters such as pH, collector dosage, % solids and

获取价格

2010/12/1 Key words: copper sulphide ores; flotation reagents; modelling; optimization 1 Introduction Froth flotation is a process used for selectively separating

获取价格

2022/6/1 The ores are concentrated through froth flotation in the form of copper-sulfide or copper-iron-sulfide minerals (e.g. chalcopyrite, chalcocite and etc.), which are

获取价格

2019/9/26 The presence of fine and ultra-fine gangue minerals in flotation plants can contribute to sub-optimal valuable ore recovery and incomplete water recycling from thickeners, with the performance of the

获取价格

2020/9/24 both cases (copper grade and copper recovery) the parameter effects are. similar to be varied. A maximum recovery of copper was 88,58% while the grade was 2,88. with 32,29 copper oxide on the ...

获取价格

2014/8/11 The flotation by surface sulphidisation of the oxidized copper-cobalt-bearing ore from Kimpe (1.97% Cu; 0.66% Co) was studied in order to evaluate its behavior by the analysis of its most ...

获取价格

2018/8/28 The flotation treatment of nickel–copper sulphide ore at the Western China nickel mine has historically been difficult due to the presence of large amounts of serpentine minerals.[1] ... Flotation tests revealed that the stirred tanks with two impellers had an advantage over those with one impeller in intensifying agitation pretreatment, and ...

获取价格

2017/1/1 Results of flotation tests were unsuccessful in terms of both recovery and grade of concentrate product. The highest copper recovery of concentrate was found as 61.35% with 8.69% copper

获取价格

2022/6/1 The ores are concentrated through froth flotation in the form of copper-sulfide or copper-iron-sulfide minerals (e.g. chalcopyrite, chalcocite and etc.), which are then melted in a high-temperature reheating furnace (± 1250 ℃). ... The results of the above flotation tests show the superiority of grinding with Na 2 CO 3 compared to those ...

获取价格

2020/8/28 In this research, flotation of copper, lead and zinc minerals from a copper oxide–sulfide ore was studied. The identification tests showed that the sample is a mixture of quartz, chalcopyrite, galena, cerussite, hemimorphite and iron oxide minerals with 5.04% CuO, 1.61% PbO, 2.07% ZnO and 56.40% SiO2. The experimental design

获取价格

2015/9/13 addition on flotation performance of a nickel sulphide ore. The objectives of the study were to: 1. develop an understanding of the effects of collector and depressant dosage, and its interactive effects, on flotation performance and 2. determine the effect of stage dosing collector and depressant on flotation performance.

获取价格

2022/9/7 The flotation tests were carried out in a Metso model D-12 cell (Helsinki, Finland). ... V. Development of online soft sensors and dynamic fundamental model-based process monitoring for complex sulfide ore flotation. Miner. ... "Response Surface Methodology for Copper Flotation Optimization in Saline Systems" Minerals 12, no. 9:

获取价格

2019/7/1 All sulphide minerals and copper oxides are concentrated in the sulphide flotation stage, whilst cobalt oxides are less concentrated or equal to the content in the feed. When comparing the information from Table 6 with the recovery per mineral in Table 4, it follows that a higher recovery of valuable minerals is accompanied with a lower ...

获取价格

2017/7/4 Copper is most commonly present in the earth’s crust as copper-iron-sulphide and copper sulphide minerals, for example, chalcopyrite (CuFeS2), bornite (Cu5FeS4) and chalcocite (Cu2S).

获取价格

2022/11/1 1. Introduction. The continuous development of the global economy has resulted in a high demand for copper production and high copper consumption [1], [2], and exploitation and effective use of copper oxide mineral resources have attracted attention [3].Copper oxide deposits evolve from shallow copper sulfide deposits after long-term

获取价格

2022/5/16 ABSTRACT. The extraction of nickel (Ni) from sulfide resources commences with flotation to produce a concentrate which is then smelted to produce a nickel-enriched phase called matte, and further refined to produce pure Ni products as well as by-products, such as cobalt (Co), copper (Cu) and precious metals.

获取价格

2013/9/1 The copper oxide ore in Dali, which contains 0.69% of copper and 11.24g/t of silver, was beneficiated by sulphidizing - xanthate flotation method. The flotation tests were carried out systematically with sodium sulfide as sulphidizing agent and butyl xanthate + ammonium dibutyl dithiophosphate as the combined collectors. Through closed-circuit

获取价格

Asghari et al. [27] investigated the improvement of copper recovery in an industrial flotation circuit (Sarcheshmeh copper mine), and stated that about 95% of overall copper lost in final tailing was in the rougher circuit while the rougher flotation recovery of mixed copper ore was 8% less than the sulfide ore.

获取价格

Key words: copper sulphide ores; flotation reagents; modelling; optimization 1 Introduction Froth flotation is a process used for selectively separating hydrophobic materials from hydrophilic. Various factors, such as the type and quantity of chemicals added[1í2], the bubble size[3], stator and rotor configuration[4] and residence time[5 ...

获取价格

2020/5/23 As part of a study investigating the influence of mineralogical variability in a sediment hosted copper–cobalt deposit in the Democratic Republic of Congo on flotation performance, the flotation of nine sulphide ore samples was investigated through laboratory batch kinetics tests and quantitative mineral analyses. Using a range of ore

获取价格

2013/9/1 The copper oxide ore in Dali, which contains 0.69% of copper and 11.24g/t of silver, was beneficiated by sulphidizing - xanthate flotation method. The flotation tests were carried out systematically with sodium sulfide as sulphidizing agent and butyl xanthate + ammonium dibutyl dithiophosphate as the combined collectors. Through closed-circuit

获取价格

Asghari et al. [27] investigated the improvement of copper recovery in an industrial flotation circuit (Sarcheshmeh copper mine), and stated that about 95% of overall copper lost in final tailing was in the rougher circuit

获取价格

Key words: copper sulphide ores; flotation reagents; modelling; optimization 1 Introduction Froth flotation is a process used for selectively separating hydrophobic materials from hydrophilic. Various factors, such

获取价格

2020/5/23 As part of a study investigating the influence of mineralogical variability in a sediment hosted copper–cobalt deposit in the Democratic Republic of Congo on flotation performance, the flotation of nine sulphide ore samples was investigated through laboratory batch kinetics tests and quantitative mineral analyses. Using a range of ore

获取价格

2015/9/17 Now that we’re all educated on sulphide flotation selectivity and its impact on mass-pull; review the 2 rougher flotation test results below and tell me if More Mass is Better?. 3 plots are provided to help in your analysis: Mass VS Copper Recovery Copper Recovery VS Total Sulfur Recovery Copper Grade VS Copper Recovery. PS:

获取价格

2016/5/16 Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the mills has continually been improved to increase production while reducing operating and maintenance costs. Also, considerable attention is paid to automatic sensing devices and

获取价格

Therefore, the main objective of the study was to optimize the process parameters for the flotation of base metals from a nickel-copper sulphide ore. 2. Materials and Methods 2. 1. Materials The nickel-copper sulphide ore used in this study was supplied by Trojan Nickel Mine located in Bindura, Zimbabwe.

获取价格

2021/2/16 Cyanidation of Copper Flotation Tailing. As described under “Flotation of Copper”, concentrates containing percent of the copper, 62.7 percent of the gold, and 61.2 percent of the silver wore made by 1-stage cleaning. The cleaner tailing from this operation were then returned to the rougher tails.

获取价格

2019/11/1 At Silver Queen mine (Canada) a combined lime-starch-SO 2 conditioning scheme is used for copper flotation from the Pb/Zn sulphides (Bulatovic, 2007b). In the process, lime (1200 g/t) and starch (200 g/t) are used first, at pH 10.5–11.2, after which the pH is reduced to 5.5 with SO 2 (200 g/t) and the copper sulphide floated.

获取价格

2015/10/10 Flotation tests were carried out using single collectors as well as various mixtures of the two collectors at different but constant total molar concentrations. Flotation performances were increased effectively by the combination of collectors. ... Thiol collectors were used in the froth flotation of copper sulphide from the slag. The xanthates ...

获取价格

2019/4/12 The aim of this study is to apply process mineralogy as a practical tool for further understanding and predicting the flotation kinetics of the copper sulfide minerals. The minerals’ composition and association, grain distribution, and liberation within the ore samples were analyzed in the feed, concentrate, and the tailings of the flotation

获取价格

The flotation tests were done using a laboratory Essa flotation machine with a 2.5 L cell. Charges of 1 kg were used in order to obtain a pulp density of 32% solids.

获取价格

Laboratory batch flotation tests were done on the sulphide composite with PAX as a collector and on the oxide composite using AM28 as collector. A third test was done on the ore blend using both AM28 and PAX collectors. Results are shown in Figure 2.8. Figure 2.8 Flotation response for copper sulphide composite using PAX as the copper collector.

获取价格

2014/11/1 1. Introduction1.1. The project requirements of laboratory flotation testing. This review discusses flotation testing at the 1–2 kg batch scale.The metallurgical engineer arranging the flotation test programme typically wants clear, unambiguous results showing “before” and “after” test conditions that are significant, cogent, reproducible, and have a

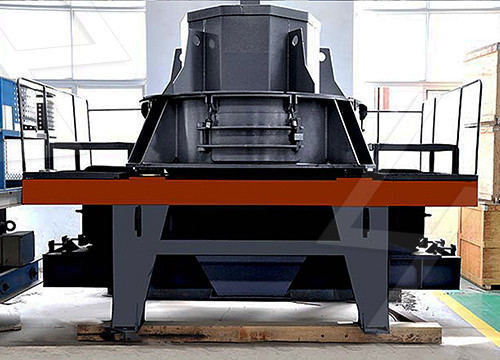

获取价格قواعد انتاج قوية، وفيرة الخبرة في التصنيع وفريق البحوث المهنية تساعد التنمية في عمق آلات التعدين. كلا النوعين المنتجات والنماذج قادرة على تلبية جميع مطالب في هذه الصناعة، وضمان الجودة وتسليم المعدات.

إذا كنت مهتمًا بشركتنا أو منتجاتنا ، فسيقوم موظفونا بتزويدك بإخلاص بمعلومات المنتج ومعرفة التطبيق والخدمة الجيدة.

بودونغ ، شنغهاي ، الصين